I've been meaning to pull the airbox and at least take a look at the throttle bodies on my old 1st gen. She's sitting at 90k miles and each time that I have checked the TBS I've noticed that it is always requiring a little bit of adjustment each time, and that the end result isn't as good in terms of minimizing vibration in the 4000-5000 rpm range that it once did.

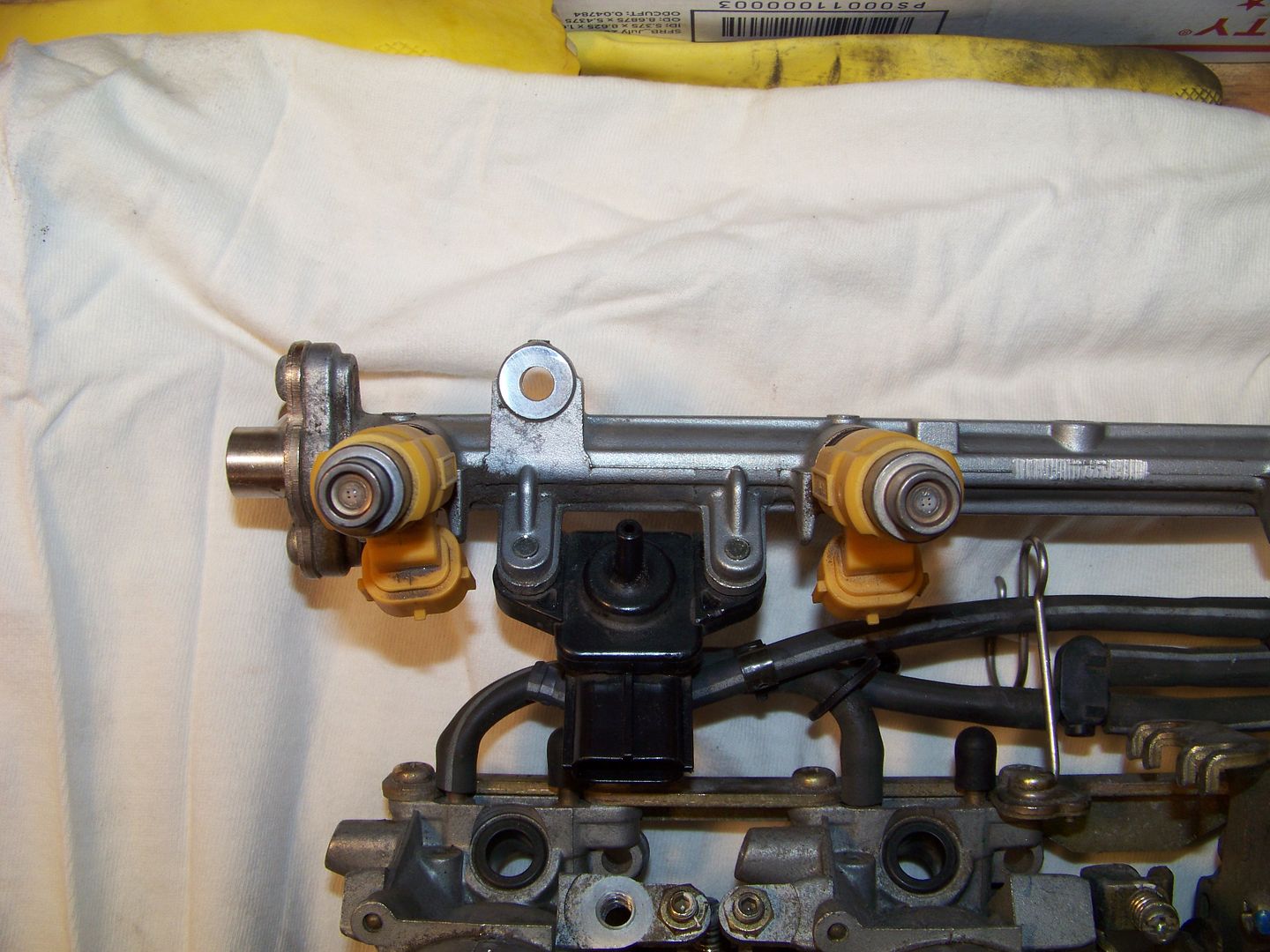

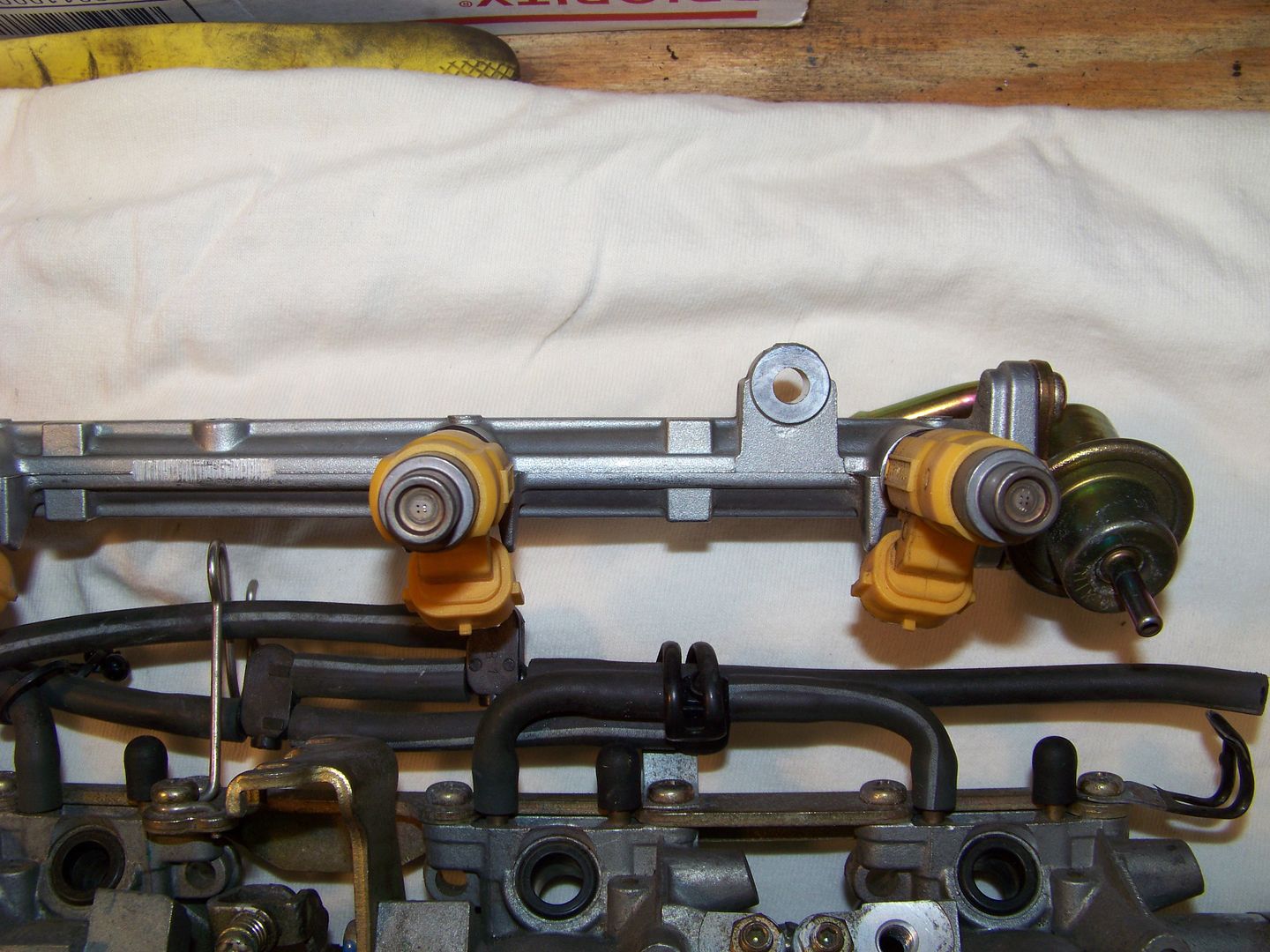

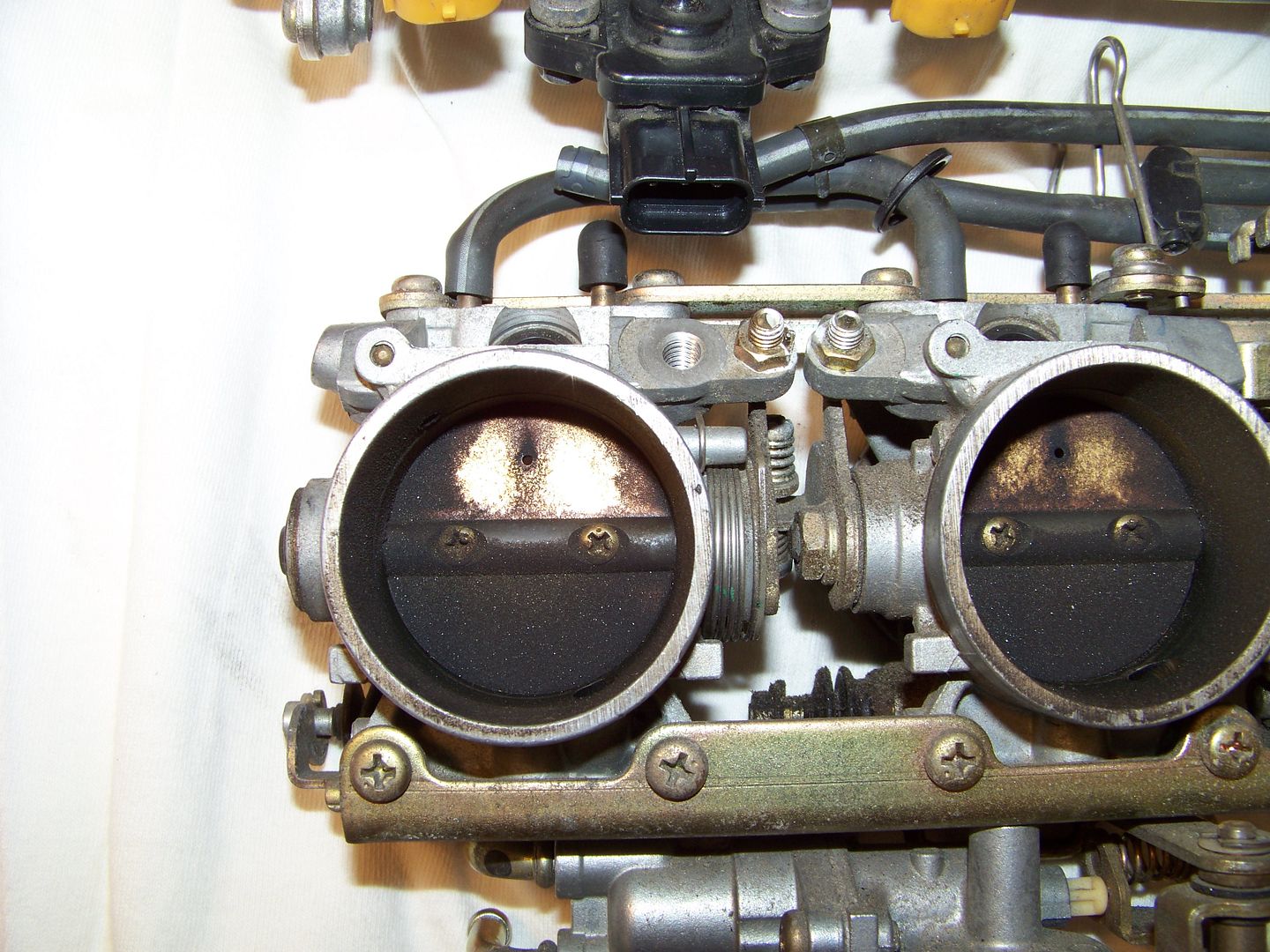

Today was the day. Pulled the tank off, Fuel rail and injectors, and the airbox and here's what I saw:

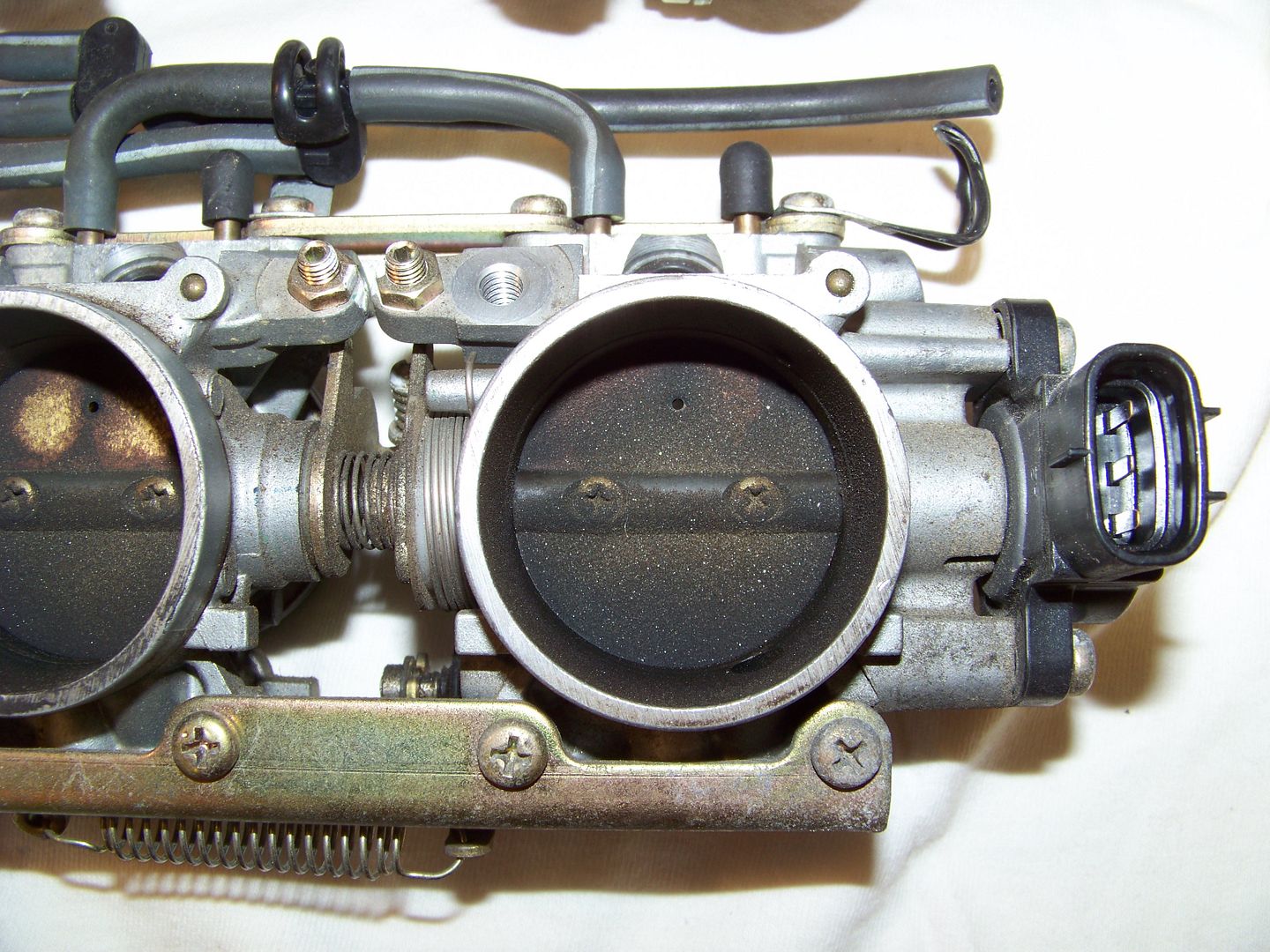

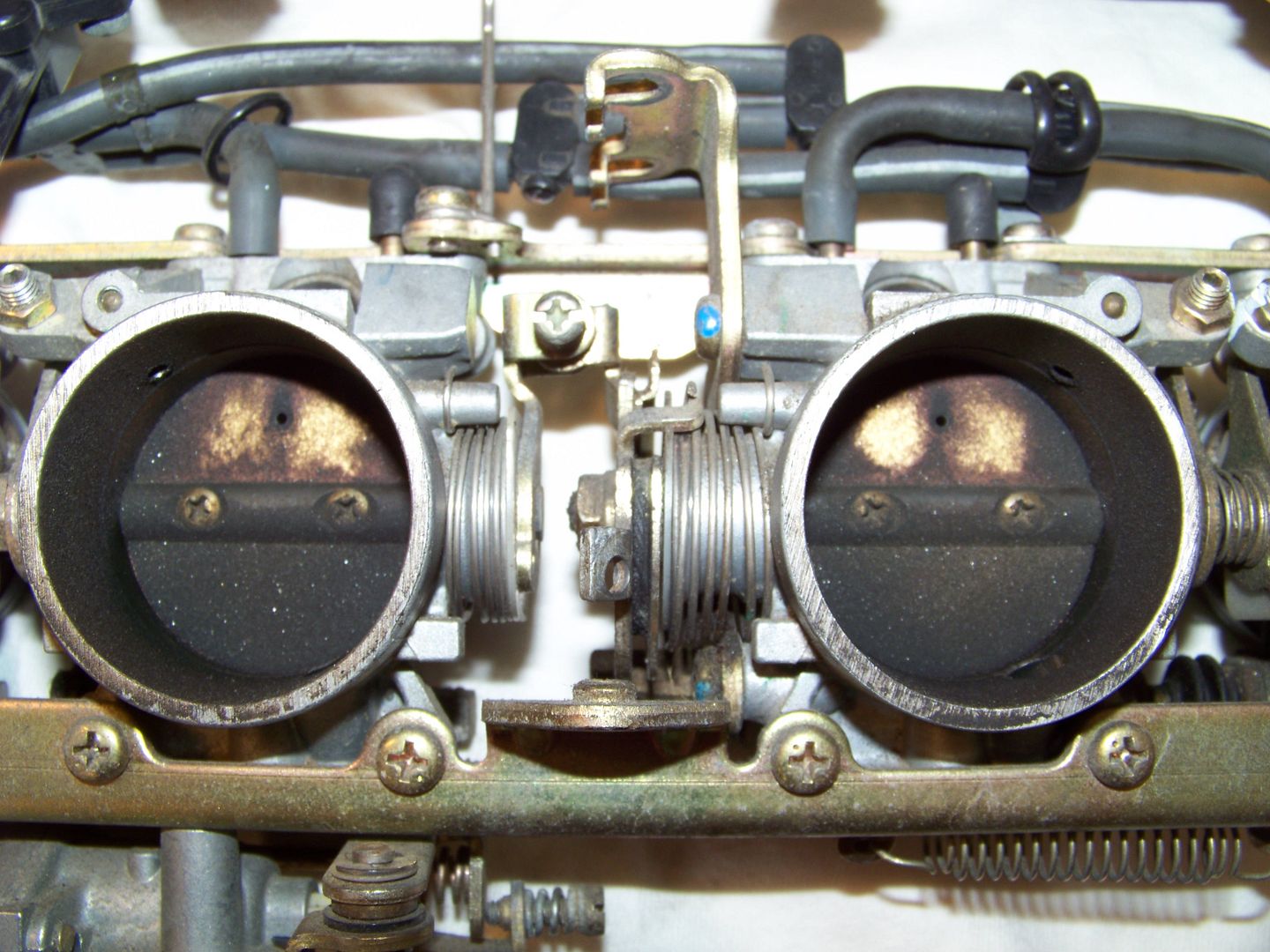

Naturally once I saw the state of those throttles I pulled the assembly off for a thorough bench cleaning...

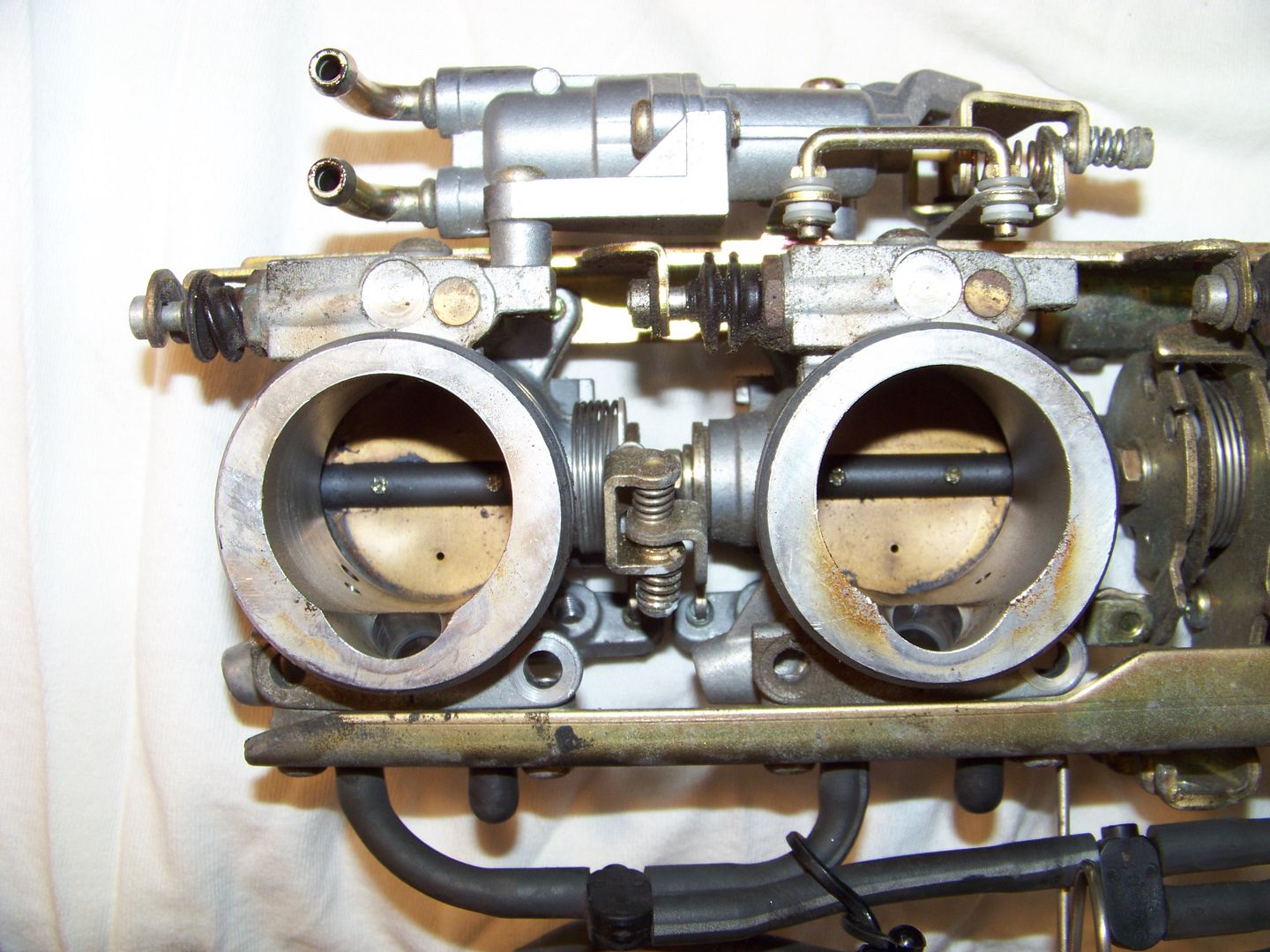

The fuel injector nozzles look pretty clean... probably because I do run a tank of seafoam mix now and then.

But looking closer at those butterflies was downright scary. Inlet side is caked with spooge and fine dirt:

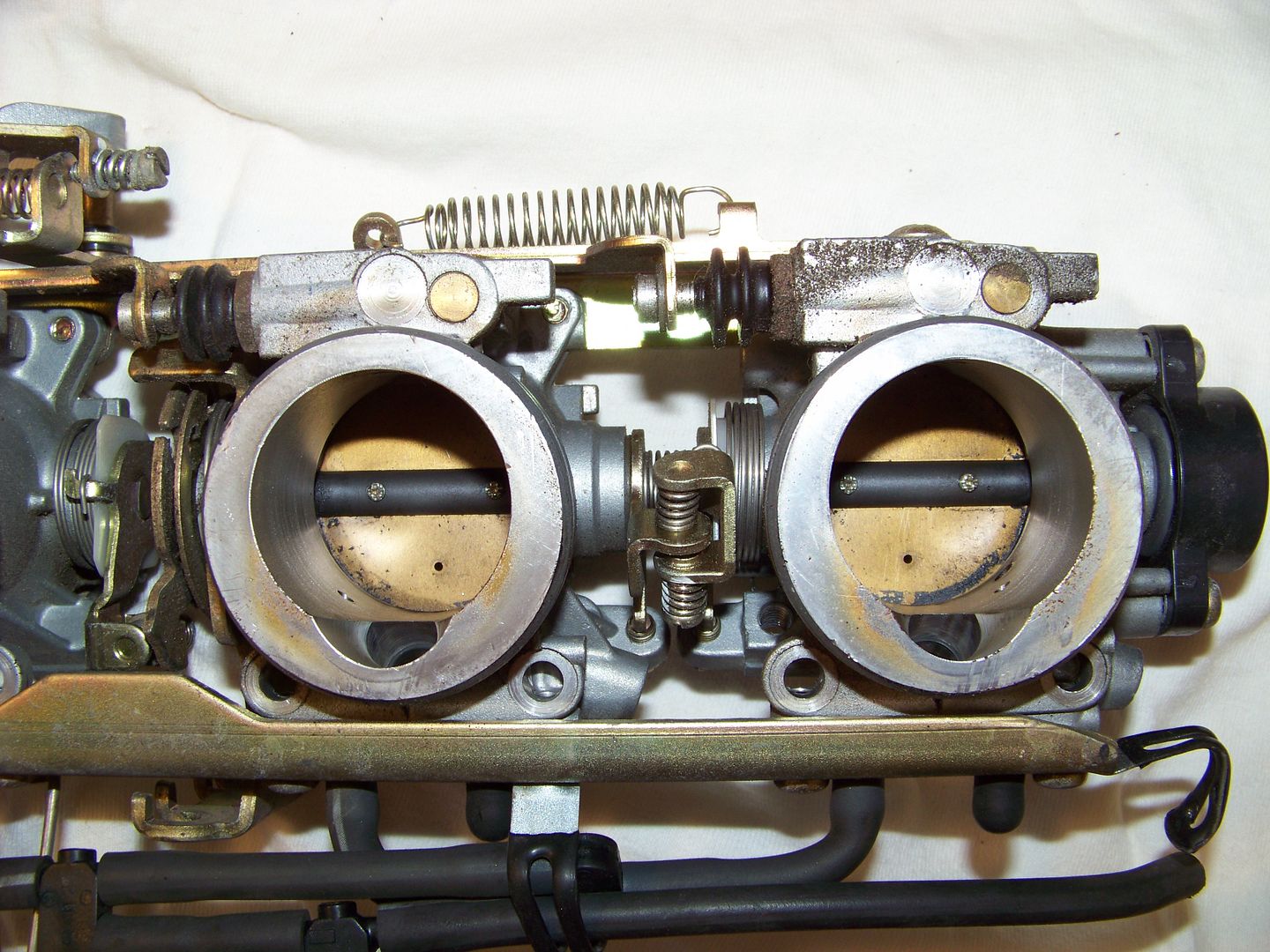

The engine side of the throttle plates did look a lot better, but the throttle bores themselves had a well developed crust all around the periphery.

As a point of reference, it took me only a little over an hour to get the bike stripped down this far and yank the bodies out, and that was slightly complicated by having a PCIII installed which doubles the connectors that need to be detached. Not all that daunting. Cleaning things up and putting it back together was a bit more time consuming, but quite easily do-able in a short day.

I did not get pictures of these next observations, and for that I apologize. But I got a bit carried away in my zeal to get this nasty crap outta there and (hopefully) restore my filthy throttles. You can see that the bores in front of the butterflies are considerably larger than the bores behind them. When you open up the throttles (by hand) you'll see that just behind the throttle plates there is a curved flare down from the larger diameter at the rear to the smaller diameter at the engine.

As the plates are cracked open, and for the first 10-15 degrees or so, the upper edge of the plates stays relatively close to that curvilinearly flared surface on the upper side of the bores as the lower edge moves rearward (toward the filter). The entire surface of these flares was well coated with black spooge buildup like the forward side of the throttle plates but without the grit. I believe it was that buildup that was causing my syncing problems lately.

Before anyone jumps in and tells me that it is all my fault because I don't wind the piss outta my bike enough (which I actually do) consider this: These plates are ahead of the fuel injectors in the airstream. This buildup is NOT going to be affected by a heavy throttle hand in the least bit. And, FWIW, before my last valve check I used Seafoam Deep Creep injected from the airbox end, in an attempt to clean the throttle plates without removing the air-box. That effort was clearly futile.

So, what's up with this crap? Folks have speculated about it since the very first first gens were looked at, but nobody has had definitive evidence to say for sure. After today I think I can rectify that. After I thoroughly cleaned the throttles with carb cleaner (went through two big cans) and a soft bristled brush to scrub away the nasty deposits, and since I had the air-box off already, I decided to split the box to clean up the innards (it just has a bunch of Philips head screws holding the two halves together.

The inside of the upper half didn't look all that bad at first glance... pretty clean and dust free actually.

And here's the lower half of the air-box with the four rubber intake snorkels. They had only a very light dust stuck to their surfaces.

But wait! What is that shiny dark stuff on the small tee shaped affair at the bottom of that last photo?

Ah ha! It's oil, that's what it is. And that is the port where the crankcase ventilation pipe (with no PCV valve or anything in line) hooks up coming from the crankcase.

Now, going back to take a closer look at the upper half of the airbox that would be directly behind that crankcase vent tee tells the full story...

Mystery solved, IMO. The free venting crankcase hose vents blow-by gasses and hot oil vapor into the "clean" side of the airbox. That oil vapor wets the throttle plates and any dust that makes it through (or around) the air filter sticks to the oily residue.

Obviously I cleaned everything up well before reassembling, and I just put everything back together as it was (for now anyway). I do like to ride me some dirt roads, and that is probably why my plates looks so gritty. I guess the FJR air filter media is not cut out to handle dusty air intake. Might be something to think about in the future.

Had there not been an oily deposit on the throttle plates none of the spooge would have deposited or built up, necessitating the big disassembly and cleaning. Maybe if we vented the crankcase through a small filter on the way to the air-box we could trap some of the oil vapor, as was suggested above by LAF (above), over three years ago.

While having to do this kind of thing every ten years or so is not overly cumbersome, I was well overdue from the looks of things. And, when I got everything back together I was extremely pleased with how well the TBS rebalanced. It required considerable adjustments of the plates (with the air screws closed down per RCDUA procedure) and then after opening the 4 air screws an equal 1/2 turn each and re balancing the balance looked very good as I revved the engine up to ~4k rpm. Very little tweaking from there.

The best part was how the bike felt afterwards on the 1 hour obligatory "Test Ride." Oh my gosh, what a difference!

At 4000 - 4500 rpm there is a complete null in vibration. 4500 is 80 mph (on a 1st gen) so cruising on the interstate is totally joyful again. I'm not kidding, the vibration at 80 mph is so low you'd swear that the engine isn't even running.