Jack D

Well-known member

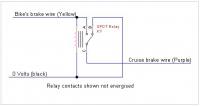

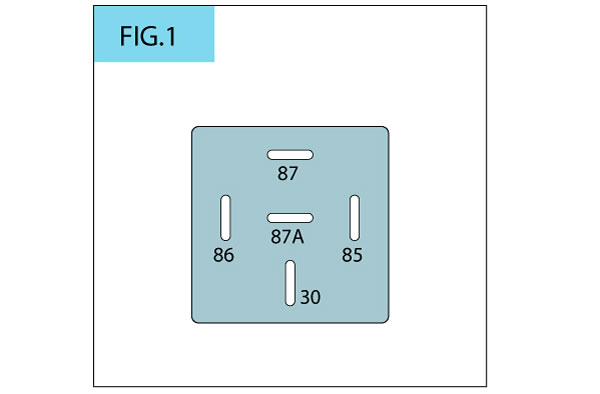

Unfortunately the Audiovox does not have the diagnostic capability of the McCruise, nor does it have the great support of the McCruise. There are 2 areas I would look at. One has already been mentioned and that is voltage on the brake light wire that will disconnect the cruise control. There are many posts about adding a relay to keep that wire grounded until the brake light is activated. It's true, do it. The second is sticky solenoid plungers. Disassemble each one carefully and clean them with alcohol. Do NOT use acetone or brake cleaner. I disagree with the people that say the cruise will shut down if the cable is too slack. I wish it did. Mine had a lot of slack and sometimes would not engage until a mile or two after I pressed the SET button. Of course we know NOTHING about the Audiovox firmware and any revisions that it may have. Maybe some shutdown from too much slack and others don't. I also question the reliability of using the ignition coil as the vehicle speed source. The McCruise uses a sensor picking up a magnetic field from 6 magnets inserted into the 6 bolts holding the disc brake rotor. I would like to try that but I have not found any 6mm diameter cylindrical magnets yet. I also tried connecting the rear wheel ABS hall effect sensor to the Vehicle Speed Sensor line of the cruise control but that did not work. The connection had no effect on the ABS. The output of that sensor swings from .5 volts to 1.5 IIRC. It also has a frequencyof pulses per mile higher than the Audiovox switch settings call for. Currently I have all 4 cylinders connected to the speed control with a check valve for each cylinder. I have a vacuum reservoir but it is currently disconnected and I notice no difference. The McCruise does not use a vacuum reservoir. I hope that something in this post provides some help for you. My next cruise control addition will be with the Rostra unit and using a speed sensor signal, but that will be on a different bike. I am satisfied with my Audiovox but it does have some quirks and definitely is lacking compared to the factory cruise.