majicmaker

Well-known member

Just make sure you don't upset the balance. [friday]Balancing beads probably won't help here.[/friday]

Just make sure you don't upset the balance. [friday]Balancing beads probably won't help here.[/friday]

They might if you put them on a string and mumble while stroking them.Just make sure you don't upset the balance. [friday]Balancing beads probably won't help here.[/friday]

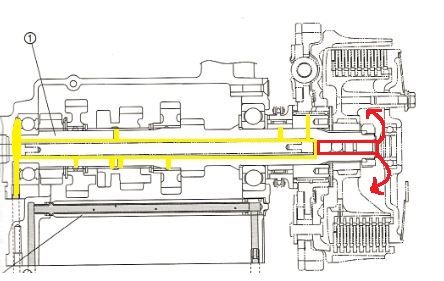

I think that you are right...Seems to me that the wrong part was drilled. Drilling the basket spins out what oil may be there trying to do its job in an already dry area. I remember reading about drilling more holes in the clutch hub - the component that the steel discs spline into. This would help distribute splashed oil to more surfaces within the clutch pack.

Just a thought

Brodie

C-Mesh,In the area you've highlighted with red there's an o-ring on the short push rod just to the right of the ball inside the axle. Don't know if the o-ring is for stopping the oil from proceeding any farther to the right onto the short rod?

You will need this,also you can buy it from a Yamaha dealerRemove the hub need a special tool?

Or, you put the bike in 5th gear on the side stand and hit the nut holding the inner hub in place with an impact wrench. Probably a good idea to have someone standing in front of the bike holding the handlebars, just to make sure the bike stays in place. Shouldn't take much effort for the impact wrench to break the nut loose.You will need this,also you can buy it from a Yamaha dealerRemove the hub need a special tool?art number :90890-04086

https://www.cmsnl.com/products/cluctc-holder_9089004086/#.V2br_9KLS00