road runner

Well-known member

Well after much screwing around I came up with another brkt. I took a page out of Harald's book, and this is what I came up with.

I used 1/8" steel, and bent it to match the underside of the plastic air deflector on the bottom tree. It's close to what Harald did, but different. Thanks Harald.

Here's how close it is to the radiator. I replaced the stock horn nut with a nylock nut, and loctite on the 2 bolts in the tree.

Here's the fender clearance. It's 5 1/2- 5 3/4". The 2x4 is 3 1/2" plus 2-2 1/4".

Front view of the horn painted flat black. Eventually I painted the brkt semi gloss black.

It fits up in there good now, and enough clearance for front travel.

I'm not offering these, just thought I'd share the ideas.

I started out with a piece of poster paper 3"x7", cut, fold it to fit up against the plastic air deflector. You will need to cut it to 2 3/8" wide so it fits up in were the bolts are. Leave the rest 3" wide, because you want the mounting hole for the horn to be toward the clutch side of the bike.

Then transfer that to a piece of sheet metal. Bolt that in, and get it to fit in place. Temporarily bolt or hold the horn in place to make sure it's going to work.

Then use the sheet metal as a template to bend the 1/8" steel. The sheet metal is thin enough it wont throw off the dimensions, as long as you put it on top of the steel, or between the steel and the plastic piece. After I got the steel to fit nice, then I cut the corners off as shown in the diagonal lines on this template.

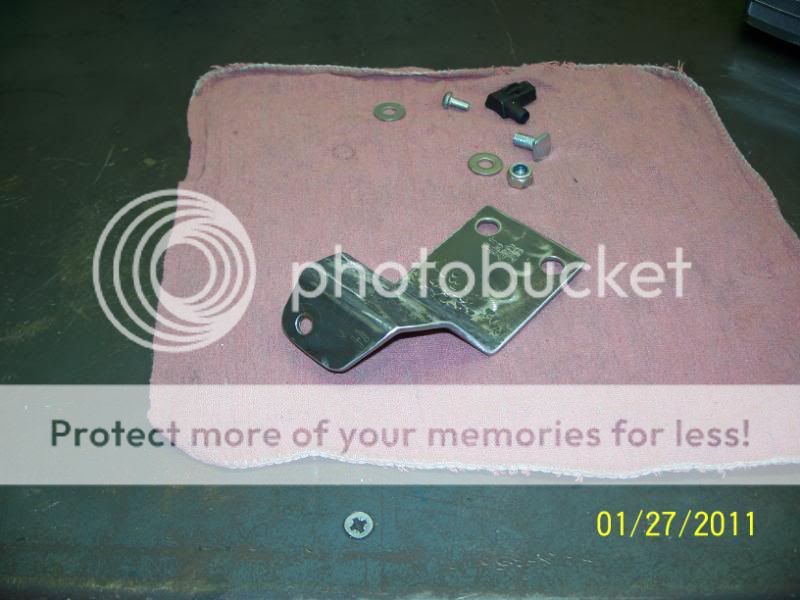

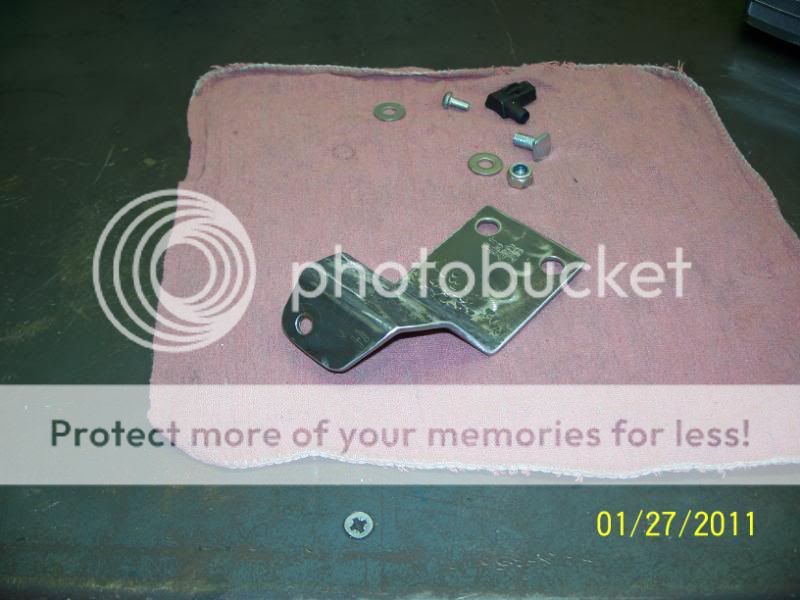

So then it looks like this.

I used 1/8" steel, and bent it to match the underside of the plastic air deflector on the bottom tree. It's close to what Harald did, but different. Thanks Harald.

Here's how close it is to the radiator. I replaced the stock horn nut with a nylock nut, and loctite on the 2 bolts in the tree.

Here's the fender clearance. It's 5 1/2- 5 3/4". The 2x4 is 3 1/2" plus 2-2 1/4".

Front view of the horn painted flat black. Eventually I painted the brkt semi gloss black.

It fits up in there good now, and enough clearance for front travel.

I'm not offering these, just thought I'd share the ideas.

I started out with a piece of poster paper 3"x7", cut, fold it to fit up against the plastic air deflector. You will need to cut it to 2 3/8" wide so it fits up in were the bolts are. Leave the rest 3" wide, because you want the mounting hole for the horn to be toward the clutch side of the bike.

Then transfer that to a piece of sheet metal. Bolt that in, and get it to fit in place. Temporarily bolt or hold the horn in place to make sure it's going to work.

Then use the sheet metal as a template to bend the 1/8" steel. The sheet metal is thin enough it wont throw off the dimensions, as long as you put it on top of the steel, or between the steel and the plastic piece. After I got the steel to fit nice, then I cut the corners off as shown in the diagonal lines on this template.

So then it looks like this.

Last edited by a moderator: