Thanks to numerous forum member comments, I just ordered the uber-cool Scala Q2 multiset on ebay. Yay!

I also used the forums' recommended supplier (Murph clicky) to have the audiovox cruise control and left-side touchpad mounting bracket shipped up here to Canada.

please note: I haven't posted a peep on this, as all the answers ARE in the old posts. (I'm a big kid now!)

About the cruise control: I have spent at least 10-12 hours searching/bookmarking/studying the wealth of information and even the illustrated installation walkthroughs that members have been good enough to share. Thanks to all of you, I'm reasonably confident that I won't be stumped tooooo badly.

One thing though, I googled 'checklist', 'pre-installation list' and any other search values I could think of but no luck.

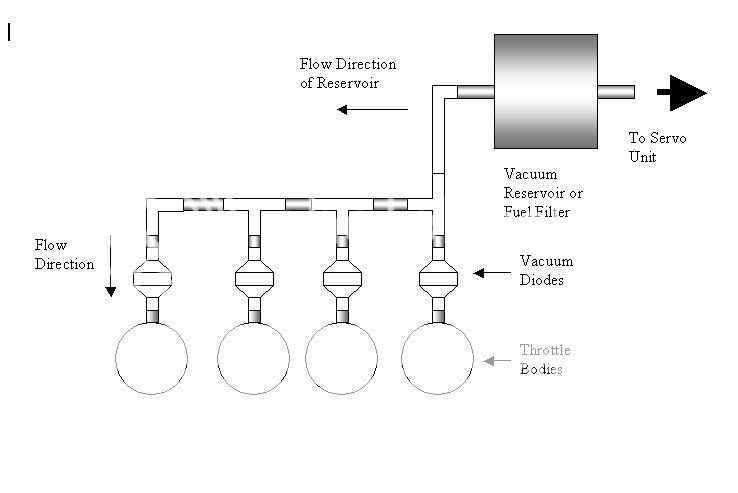

So I'm not stuck making numerous mid-project trips to the auto parts store or hardware store etc... is there such a thing as a pre-installation shopping list / checklist? Never mind about the vaccum reservoir, that I have figured-out. I'm talking about vacuum check valves, zip ties & those types of little odds & ends.

mine's a gen1, if that makes a difference

I also used the forums' recommended supplier (Murph clicky) to have the audiovox cruise control and left-side touchpad mounting bracket shipped up here to Canada.

please note: I haven't posted a peep on this, as all the answers ARE in the old posts. (I'm a big kid now!)

About the cruise control: I have spent at least 10-12 hours searching/bookmarking/studying the wealth of information and even the illustrated installation walkthroughs that members have been good enough to share. Thanks to all of you, I'm reasonably confident that I won't be stumped tooooo badly.

One thing though, I googled 'checklist', 'pre-installation list' and any other search values I could think of but no luck.

So I'm not stuck making numerous mid-project trips to the auto parts store or hardware store etc... is there such a thing as a pre-installation shopping list / checklist? Never mind about the vaccum reservoir, that I have figured-out. I'm talking about vacuum check valves, zip ties & those types of little odds & ends.

mine's a gen1, if that makes a difference

Last edited by a moderator: