Ah! A very nice improvement for the FJR.

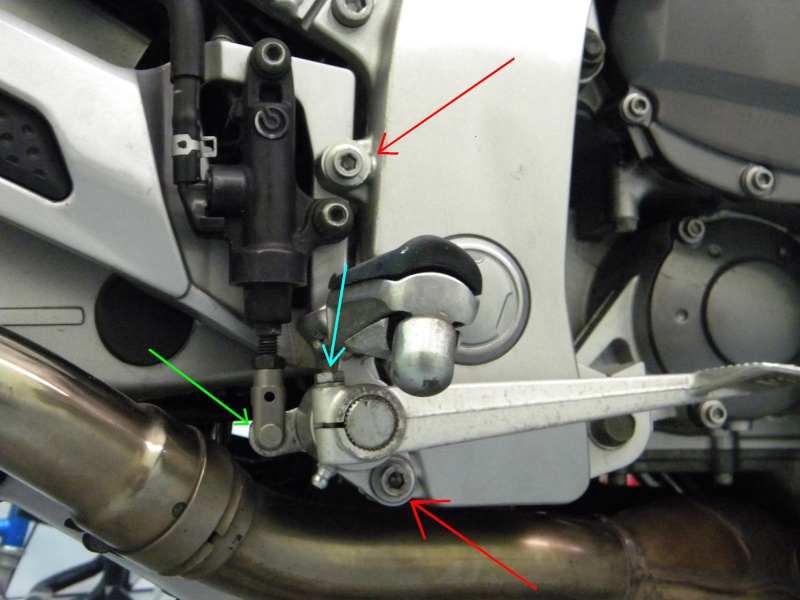

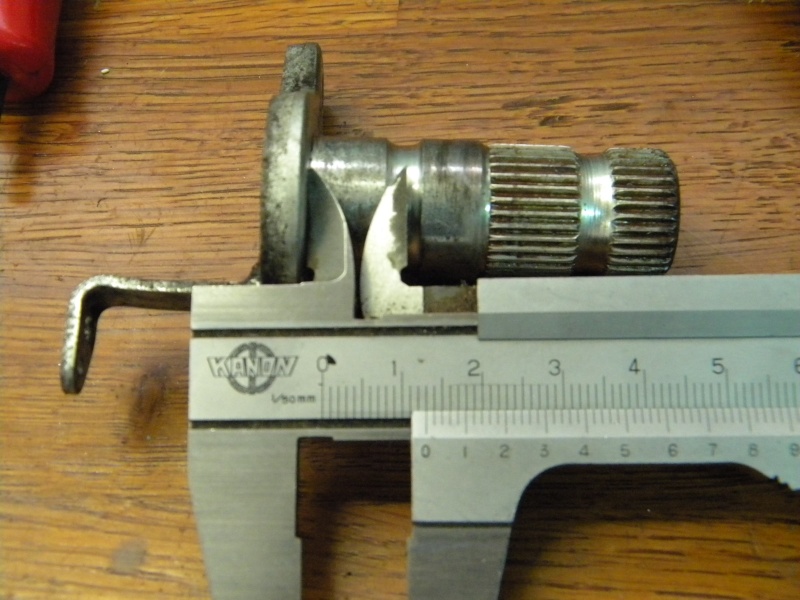

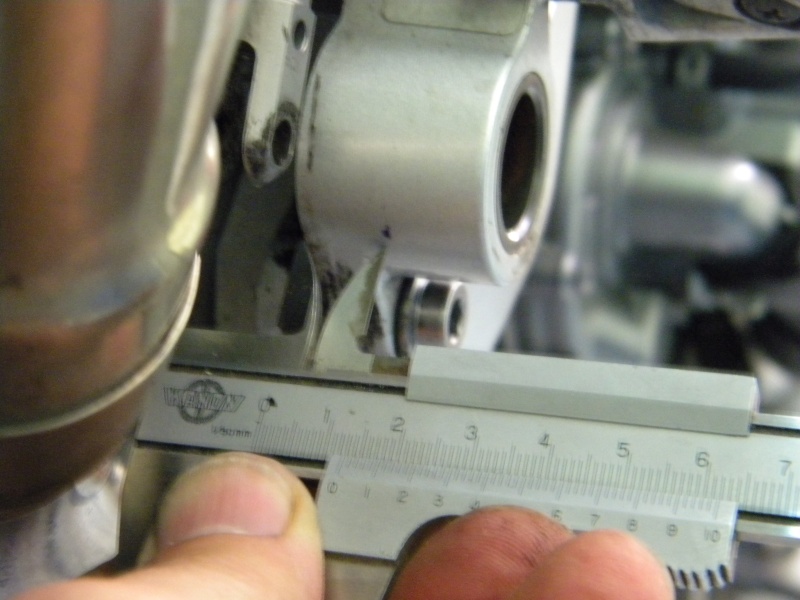

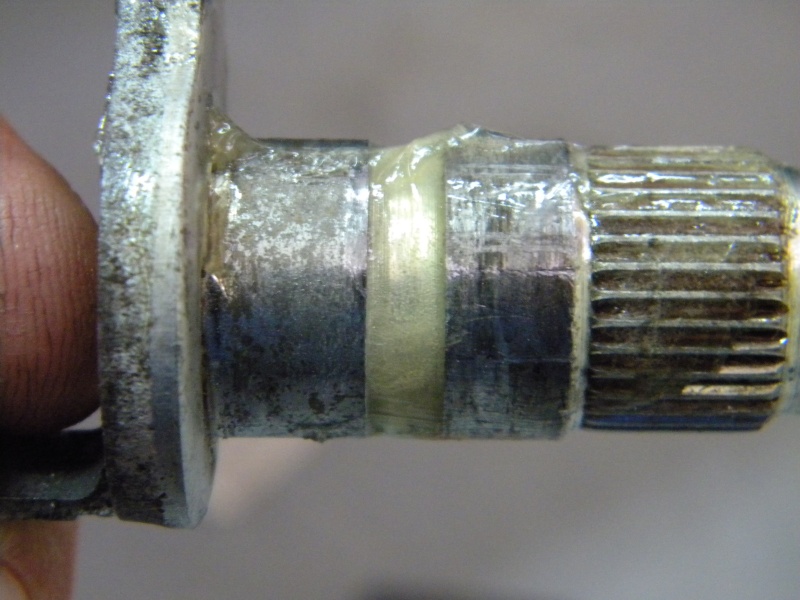

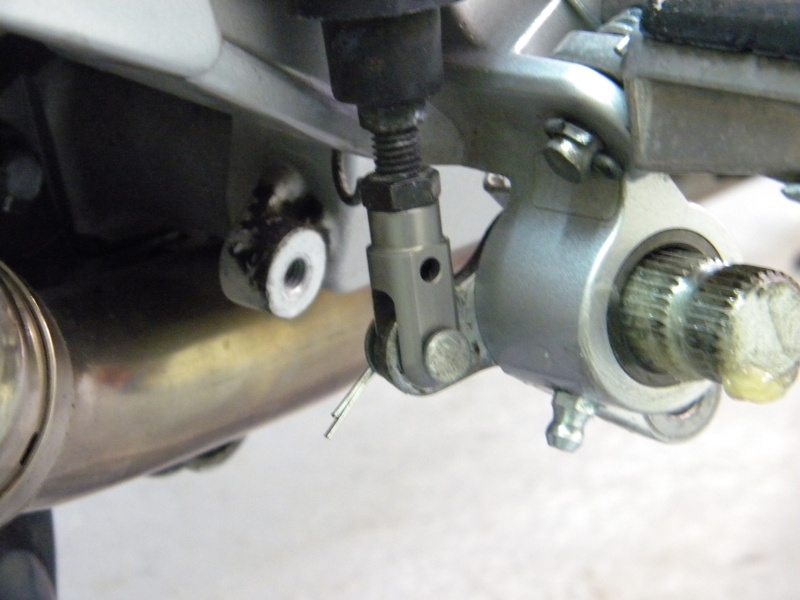

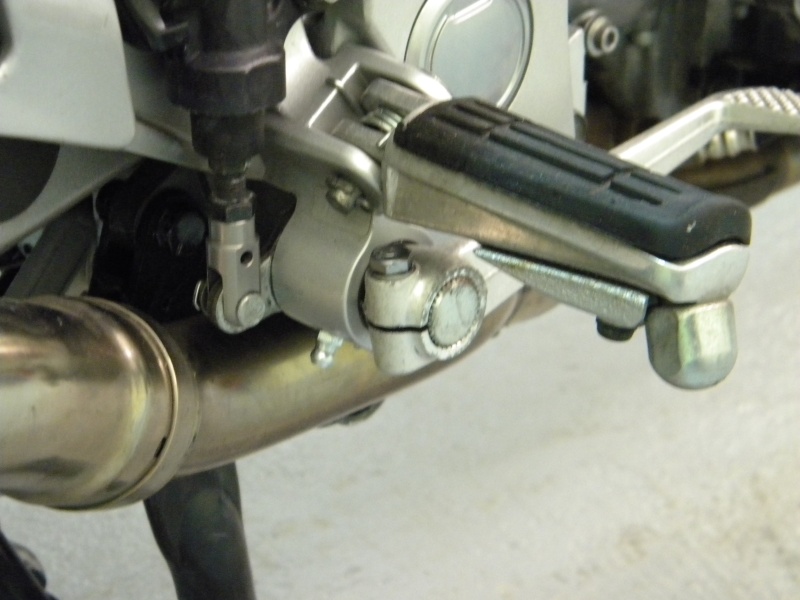

Fred's photos show the mysterious chunk of ballast metal on the underside of the footrest.

After having that pedal/footrest bracket removed do you see any simple mod which would reduce the transmission of engine vibration to the footrest? It's not a big problem but if the vibes could be easily attenuated it would be welcomed.

Fred's photos show the mysterious chunk of ballast metal on the underside of the footrest.

After having that pedal/footrest bracket removed do you see any simple mod which would reduce the transmission of engine vibration to the footrest? It's not a big problem but if the vibes could be easily attenuated it would be welcomed.