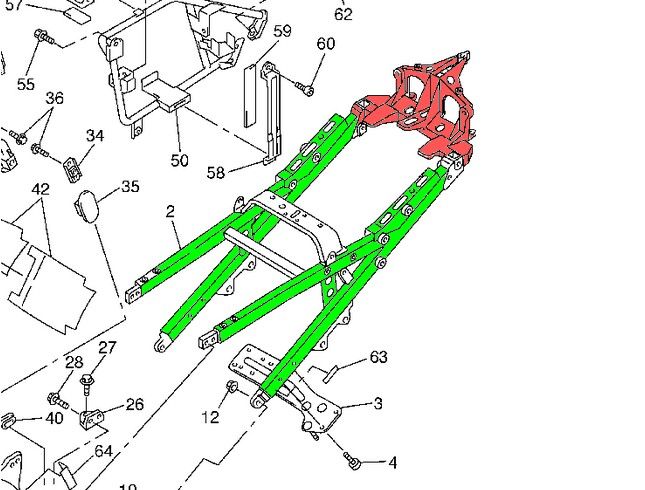

Unfortunately, in this scenario, the Givi rack is also supported by the rear subframe.

I agree that the Givi SR357 frame looks much more robust than the POS Yamaha plat and grab (and snap off) rails, keep in mind that it doesn't remove much of the weight from the rear subframe. The part that bolts under the seat is effectively only the front pivot point for the load.

To prove this, think about mounting this rack using only the under-seat mounting bolts. The rear-most part would easily flex up and down, until it too is bolted down.

Most of the weight is still supported by the rear subframe. You'd need another, even further forward, point of attachment to remove most of the load from the rear.

It's fizix.

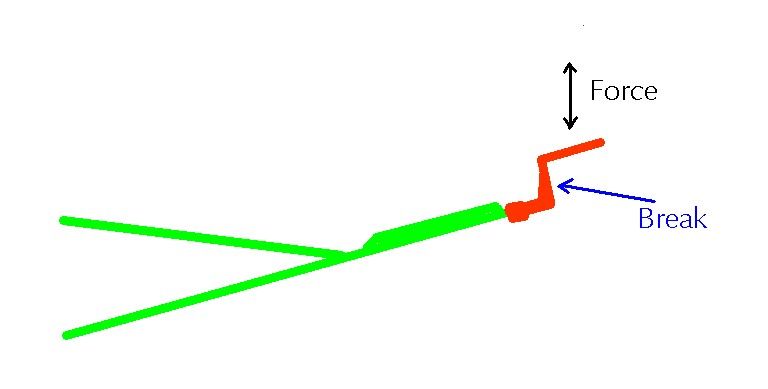

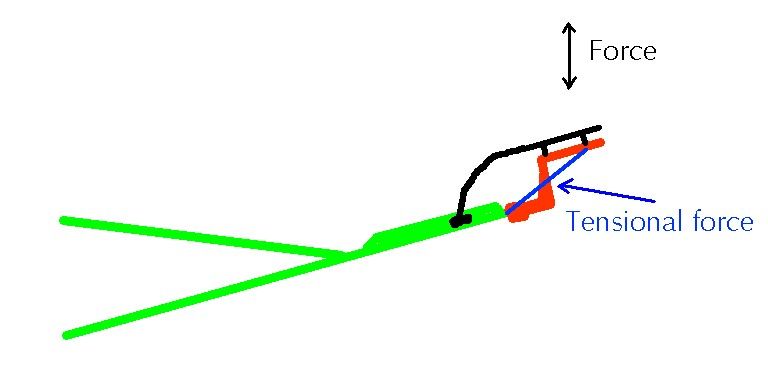

That is true. The weight is still borne primarily on the three rearmost mounting points. But what the arms do provide is a triangulation of the structure so that the cast rear part of the subframe isn't allowed to flex around with the trunk out there bouncing around. That is what causes the cast piece to break, not sheer downward force of the weight.

Look where these subframes usually crack

The Givi rack ties the top piece (that is broken off in this picture) to the tubular steel part of the subframe keeping it from flexing under the cantilevered force of the trunk, which is what shatters that casting.

I do not recall anyone having a broken sub-frame casting who had a (healthy) Givi trunk mount installed. There were some Givi racks that cracked welds when severely overloaded, but I do not know what happened to the sub-frames in those cases if anything.