bucky

Well-known member

Just wondering what sort of compensation Yamaha will offer to those who made fixes proactively or after the fact while out of warranty on their own dime.

Traveling my ass off busy as Hell. All the Airplanes are Flying again. Thank God!! Hell Yeah we need to go ride! :clapping:Dude, where the hell YOU been?????This is The Best F@#King Forum EVER!! :yahoo:

We need to go riding! (once it cools off a bit and stops raining!)

I agree with Woketman, Good Luck with That!Just wondering what sort of compensation Yamaha will offer to those who made fixes proactively or after the fact while out of warranty on their own dime.

Amen, let's ride. :yahoo:Dude, where the hell YOU been?????This is The Best F@#King Forum EVER!! :yahoo:

We need to go riding! (once it cools off a bit and stops raining!)

MCATrophy,If the wire gauge was the problem, the wires would be heating up inside the loom where they are even less cooled than when exposed to the air near the connectors. The wire only burns when the spider contact gets hot and then only with conducted heat from the spider.Whether or not the insulation actually bursts into flames I don't know, but if it did it would increase the damage to the wire. BUT ONLY NEAR THE SPIDER... from their teeny 20 (?) gauge wires that become overburdened. ...

Of course, once the wire is burnt, it will be thinner, its resistance will go up, it will start self heating. But only after the damage has been done.

How about the square root of -1 ?...Does the square root of zero sound about right????

I believe at least one Ground Spider failure was reported by an owner some miles after he took the time to inspect and clean all ground spiders and they pack with di-electric grease upon re-assembly.One of the issues is clean contact avoiding oxygen and other contaminants. Die Electric Silicon Grease at these connections will insure protection against atmospheric contamination.

I think we are in total agreeement, that the initial problem is the connector, not the wire.MCATrophy,If the wire gauge was the problem, the wires would be heating up inside the loom where they are even less cooled than when exposed to the air near the connectors. The wire only burns when the spider contact gets hot and then only with conducted heat from the spider.Whether or not the insulation actually bursts into flames I don't know, but if it did it would increase the damage to the wire. BUT ONLY NEAR THE SPIDER... from their teeny 20 (?) gauge wires that become overburdened. ...

Of course, once the wire is burnt, it will be thinner, its resistance will go up, it will start self heating. But only after the damage has been done.

The reason wires get hot is resistance, there is no resistance in the wire in the loom, the resistance builds in areas of of corrosion near the spider connections, the ends of copper wire transfer heat better than the steel connections, as the heat rises, more corrosion builds up to the point of failure. One of the issues is clean contact avoiding oxygen and other contaminants. Die Electric Silicon Grease at these connections will insure protection against atmospheric contamination.

FWFE

And thanks to all whose effort has not gone unnoticed.

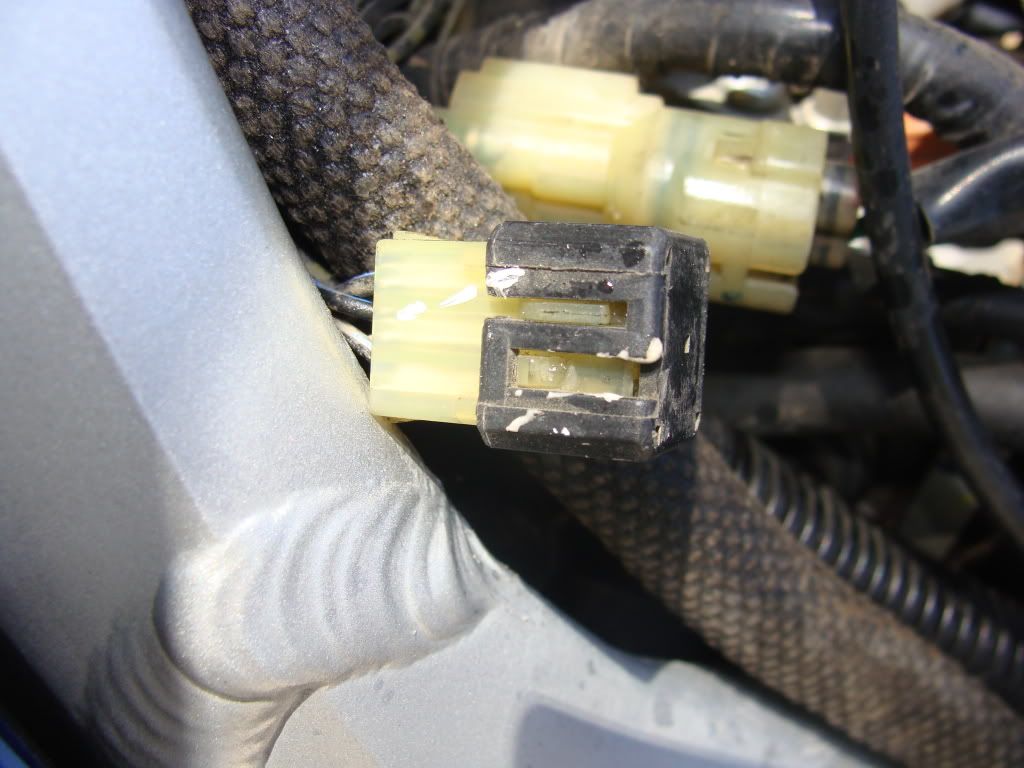

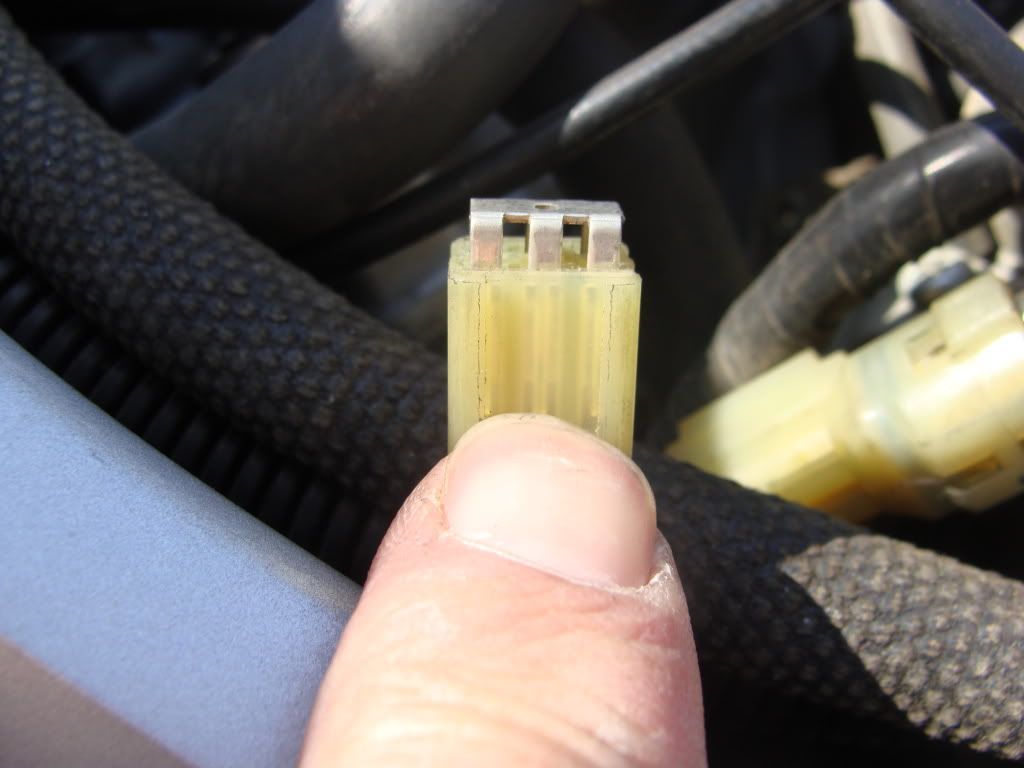

All the following pictures are stolen from dcarver without his knowledge or consent. But damn, he did such a good job.What's a spider and why are they in my bike?

Ignore the issue and you WILL be in the dark....at 60mph on an unlit backroad.Sometimes it's better to be in the dark.

That was me. I made it to Yellowstone from PA and there I sat, in Tower Falls parking lot, funny dash lights and too silent. I think it was 3 weeks from dielectric grease to cooked spider. The rubber cap was slightly bubbled, and the one spider leg was brown-ish colored. I think all the dielectric grease did was help keep the heat down, the metal to metal contact was still oxidized. I cleaned the spider, put it back in, and nothing happened. I even swapped a spider for a spider. That worked, and I rode 1/2 mile and S4 fried again! Managed a U-turn while stalled and coasted the 1/2 mile back down the hill to Tower Falls parking lot. $1200 towing later I am at my hotel in Cody.I believe at least one Ground Spider failure was reported by an owner some miles after he took the time to inspect and clean all ground spiders and they pack with di-electric grease upon re-assembly.One of the issues is clean contact avoiding oxygen and other contaminants. Die Electric Silicon Grease at these connections will insure protection against atmospheric contamination.

Enter your email address to join: