RadioHowie

I Miss Beemerdons!

It's one of those nights where everything falls in place. You make plans...you gather your resources together...and you get 'er done.

I've got a full plate this week at work, so tonight was the only night I had to re-hang Grumpy's motor in my frame. Called on the way home from work to make sure both my "assistants" would be available, got home, changed straight into work clothes and hit it.

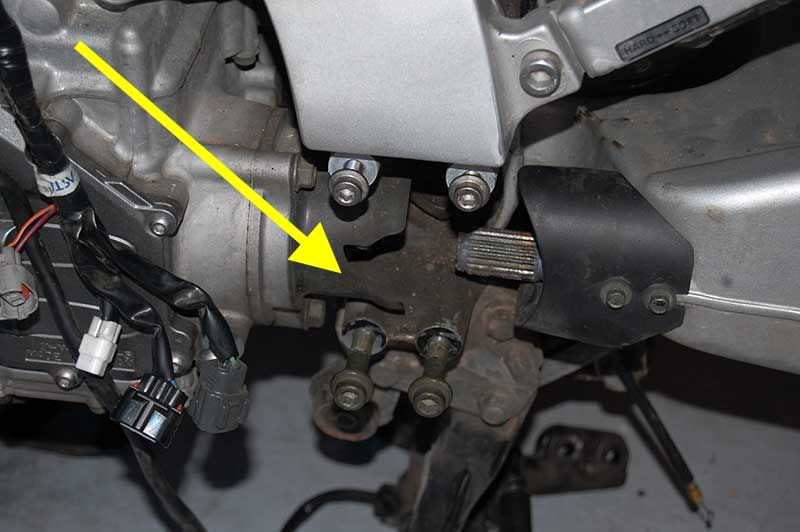

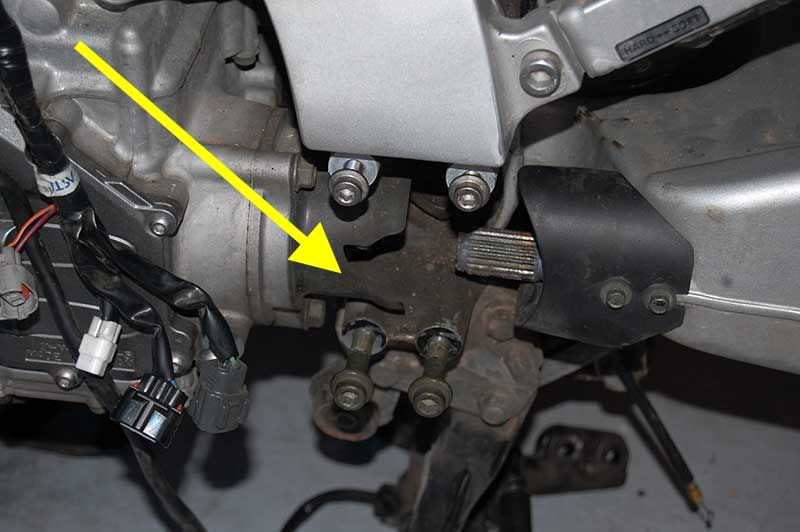

Lining up the motor to the frame:

And then the photo documentary stops. Nothing wrong with the camera, it's just that getting the motor OUT is 10 times easier than getting it back in. Maybe 20 times easier.

Any of you that have ever done your own work on your FJR knows that there is NO surplus of room between the motor and the frame. Clearances are literally in the millimeters range. Taking the motor out is much easier because you have gravity on your side, not to mention you're going from a very tight place to a very loose place.

Well to make a long story short, if you're ever going to R&R a motor, take some advice from someone who just finished the job 20 minutes ago.....put the motor up on a suitable stand, a crate, a low work table, about 2 feet off the ground is more than enough. Fix up some kind of hoist arrangment and lift the frame OVER the motor and set it down in place.

I didn't have anything to put the motor on. Couldn't have lifted it up that high even if I did, and don't have a hoist. After struggling for 45 minutes with the motor on a jack, trying to wiggle it into the right position and pivoting the frame on the centerstand down in place, I gave up. Even with two strapping young helpers, it's nearly impossible, since the frame is coming down in an arc using the centerstand as a pivot. The frame must come down over the motor nearly vertically to clear everything. And balancing a nearly 300 pound motor on a jack is NO fun. There was a casualty. It slipped off the jack and fell to the floor....easy Grumpy, it's okay -- it was only about 2 inches....and the only damage was to the dust cover that encompasses the output shaft/U-joint.

Bent like a paper cup. But I'll replace it with the one from my dead motor.

Finally put the motor down on the floor, lifted the frame up off the centerstand, kicked up the stand, and set it down on the motor. A wiggle here...a wiggle there...and all 9 motor mounts lined up like they're suppposed to. Snugged everything up, pivoted the entire frame/motor assembly forward enough to deploy the centerstand, tilted it back using the rear subframe as one-half of an expensive see-saw and put jackstands back under the lower frame castings.

So guess what? The ***** is back in the frame ready for the million and a half things left to do to hook everything back up!! :yahoo:

Sorry there's not step-by-step. It's just a matter of getting the frame over the motor then get out the elbow grease and starting wiggling until **** lines up. Nothing technical about it. It's 100% grunt work.

Remember, if you ever do this, get a hoist for the frame. You won't regret it.

Next...rear end and rear wheel, exhaust, radiator and front end. Oh...torque down those motor mounts!

It's gonna be a busy Saturday.

'Howie

I've got a full plate this week at work, so tonight was the only night I had to re-hang Grumpy's motor in my frame. Called on the way home from work to make sure both my "assistants" would be available, got home, changed straight into work clothes and hit it.

Lining up the motor to the frame:

And then the photo documentary stops. Nothing wrong with the camera, it's just that getting the motor OUT is 10 times easier than getting it back in. Maybe 20 times easier.

Any of you that have ever done your own work on your FJR knows that there is NO surplus of room between the motor and the frame. Clearances are literally in the millimeters range. Taking the motor out is much easier because you have gravity on your side, not to mention you're going from a very tight place to a very loose place.

Well to make a long story short, if you're ever going to R&R a motor, take some advice from someone who just finished the job 20 minutes ago.....put the motor up on a suitable stand, a crate, a low work table, about 2 feet off the ground is more than enough. Fix up some kind of hoist arrangment and lift the frame OVER the motor and set it down in place.

I didn't have anything to put the motor on. Couldn't have lifted it up that high even if I did, and don't have a hoist. After struggling for 45 minutes with the motor on a jack, trying to wiggle it into the right position and pivoting the frame on the centerstand down in place, I gave up. Even with two strapping young helpers, it's nearly impossible, since the frame is coming down in an arc using the centerstand as a pivot. The frame must come down over the motor nearly vertically to clear everything. And balancing a nearly 300 pound motor on a jack is NO fun. There was a casualty. It slipped off the jack and fell to the floor....easy Grumpy, it's okay -- it was only about 2 inches....and the only damage was to the dust cover that encompasses the output shaft/U-joint.

Bent like a paper cup. But I'll replace it with the one from my dead motor.

Finally put the motor down on the floor, lifted the frame up off the centerstand, kicked up the stand, and set it down on the motor. A wiggle here...a wiggle there...and all 9 motor mounts lined up like they're suppposed to. Snugged everything up, pivoted the entire frame/motor assembly forward enough to deploy the centerstand, tilted it back using the rear subframe as one-half of an expensive see-saw and put jackstands back under the lower frame castings.

So guess what? The ***** is back in the frame ready for the million and a half things left to do to hook everything back up!! :yahoo:

Sorry there's not step-by-step. It's just a matter of getting the frame over the motor then get out the elbow grease and starting wiggling until **** lines up. Nothing technical about it. It's 100% grunt work.

Remember, if you ever do this, get a hoist for the frame. You won't regret it.

Next...rear end and rear wheel, exhaust, radiator and front end. Oh...torque down those motor mounts!

It's gonna be a busy Saturday.

'Howie