luvtoride

My Indian name is "Pants On Fire"

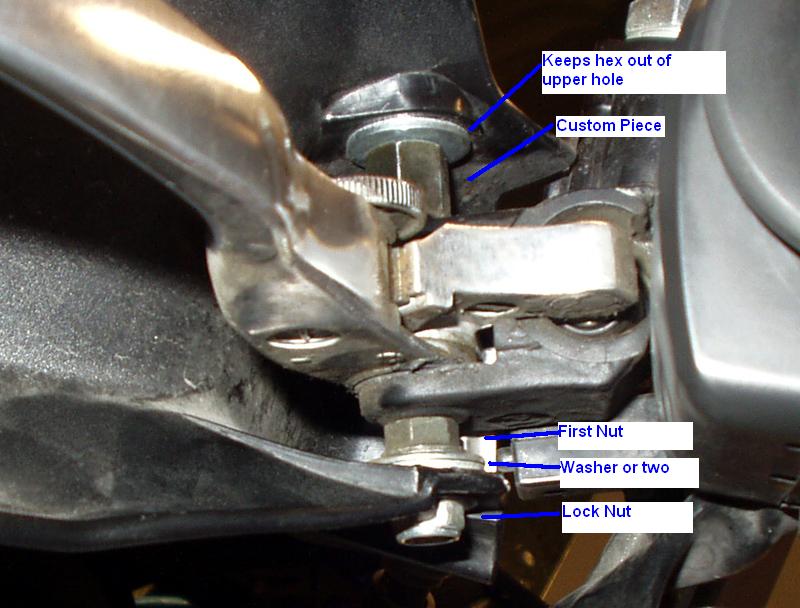

Well, after a good solid month to month & 1/2 I finally received the hardware that I ordered to do this. After looking in the little plastic baggies & seeing which screw fits what bolt & thinking... "man, I could've bought 3/4 of this shit in the hardware store"... I'm a little confused about which piece of hardware goes where. Well, in reality, some of it is pretty obvious but there almost looks like there'd be extra nuts. Now, I know them pups go somewhere!

I went to the FJR Tech page that talks about installing these but no info on the order of nuts and bolts & no really descrptive pics of the nut/bolt install. I decided to come on over here and ask if anyone can give me the exact order of their assembly.

Pics or a verbal decription would be so helpful.

Thanks in advance fellow pilots, Heidi

I went to the FJR Tech page that talks about installing these but no info on the order of nuts and bolts & no really descrptive pics of the nut/bolt install. I decided to come on over here and ask if anyone can give me the exact order of their assembly.

Pics or a verbal decription would be so helpful.

Thanks in advance fellow pilots, Heidi