FJRay

Well-known member

I don't know if you have it figured or not allthough you mention it a number of times. The bronze ( big diff between brass and bronze ) is far more wear resistant than the rest of the aluminum engine. Thats why Bronze is used for bearings world wide and the bronze parts just sit there so there in nothing to create shavings. If you read the notes you will see that I used bronze because thats what I had. The bushing could be made out of plastic and work just as well as tool steel. The spring and the other bronze piece can be eliminated if you want. The purpose of the spring is to take up any change in tension as the chain rotates around the sprockets because all chain drives have tight and loose spots. After you look at the stock one you will understand why folks are having problems. The spring gets weak or breaks and there is nothing to keep it from backing off and letting the chain jump timing. In mine even if the spring broke it wouldn't back off enough to allow this. As far as the grade of the bolt you said you would prefer a grade 3 to a grade 5. In the bolt world the larger the number the harder the bolt so you seem to not have it figured out . No offense taken and critique all you want just figure it out first. Reengineer it any way you would like.Let me see if I've got this figured out correctly, the spring in your set-up holds the plunger against the CC and the long screw takes up the slack. The brass/bronze plug in your set-up is being used for the adj. screw end to ride against while the other end fits the spring ID. I would think that the brass/bronze plug would be to soft and may contaminate the engine with brass/bronze shaving? If this is possible then wouldn't a steel plug work better or is this part of the plunger assembly isolated from getting into the engine as it's sealed from the engine by the bushing? But even if the soft shavings from the plug can't get into the engine they can still score or implant themselves into the bronze bore making the plunger assembly bore not as smooth which could result in the plunger assembly dragging or sticking in the bore? If I have this figured out correctly the adj. screw/bolt in your set-up would have some pressure on it from the spring? If so I'd still have at least a grade 3 screw/bolt to account for the spring pressure. This might be "overkill" but that's just me as I don't trust the hardware store garden variety screw hardness. I guess I'm a little confused as the heading for this thread said "Manual CC Adjuster" when in reality it's a modified manual/spring CC adjuster just like the stock unit?The screw is about a grade 5 so it is way stronger than the aluminum threads in the housing. The stock bolt is only a cork to fill the hole so strength is no issue. I agree a socket head would be nice but one was not avaliable at the time which means it wasn't in my bolt bin.Nice job FJRay! Personally I'd use a heavier grade screw or bolt (Allen head?) than the hardware store version which I think is kinda soft? Don't know what grade bolt the stock one is but I'd at least try and match that or I presonally would go up one grade higher as I live by the word "BulletProof"!There seems to be some interest in this so I will put it out there for folks to do what they want to with it. I have yet to install it because mine only has a few miles on the new one in it so I am waiting for snow fall before I get into it. I am certain it will work just fine.

This shows the stock cct disasembled and in order of assembly.

This shows the cct with the new parts in order of assembly.

This shows the parts that need to be made or purchased

This shows it all together again.

The bushing that needs to be machined can be made out of most any material. I used bronze because I have lots from my boatyard days.

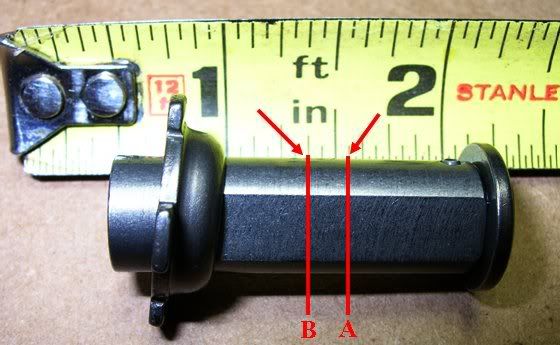

The OD is .711, the ID is .474 and the length is 1.460. All dimensions are +- .001

The spring came from Ace and is a .250 compression spring shortened to .750.

The small button goes in the end of the spring to servw as a base for the screw so it doesn't go into the spring. It is .250 on the big end and is .178 on the small end and is .330 long.

The screw is a standard 6mm x 55mm which is the same as the bolt in the end of the stock cct.

You need to run a 6mm tap through the cct body because the stock threads don't go all the way through. at this point clean up everything and get ready for assy.

I used some grease on the spring and button to keep them from falling out. Put the spring and button in the plunger from the cct. Assemble the plunger and the bushing into the cct housing and install the retainer clip. The original screw,sleve and spiral spring get discarded at this point.

The 6mm x 55mm screw along with the crush washer from the bolt go in the other end. Add a 6mm nut to the screw to act as a lock to hold adjustment.

Install in the engine as you would with the stock unit. If the screw is to long for assy then leave it out until the unit is installed and then put it in with a long screw driver.

For adjustment I would run the screw in until you feel a slight resistance and then go 1 turn to tension the spring. When I put mine in I will start the engine and slowly back out the adjuster until I get some noise and then in until it is quiet and then the 1 turn for tension.

I have no doubt that this will work just fine and require very little service.

If you want to wait until winter I will post up the results on mine.

After looking at the stock CCT pics it almost looks like a manual CCT with an adj. screw in the middle. So the thingy next to the housing must be a spring? So let me see if I've got this right? The stock CCT has an adj. screw that takes up all the free play in the CC and the spring then applies the correct pressure to keep the plunger seated against the CC loose spots? Also on the stock set-up I can see the small short screw that seals the hole for the CCT adj. screw mechanism. Just trying to understand the stock CCT and your up-graded one. No offense meant just trying to critique your set-up so if needed you can improve your design. And yes I've got the FSM just hadn't got around to the CCT yet.

Last edited by a moderator: