My Haynes manual says the following:

"Clean the holder bolts, then lubricate with clean engine oil and fit them into the holders. Got the holders in their correct position and [correct] way round. Tighten the bolts evenly and a little at a time in a criss cross pattern, working from the center of the head outwards (i.e starting with the bolts that are above valves that will be opened when camshafts are tightened down), to the torque setting specified at the beginning of this chapter." which is 10 Nm or 7.3 pound ft.

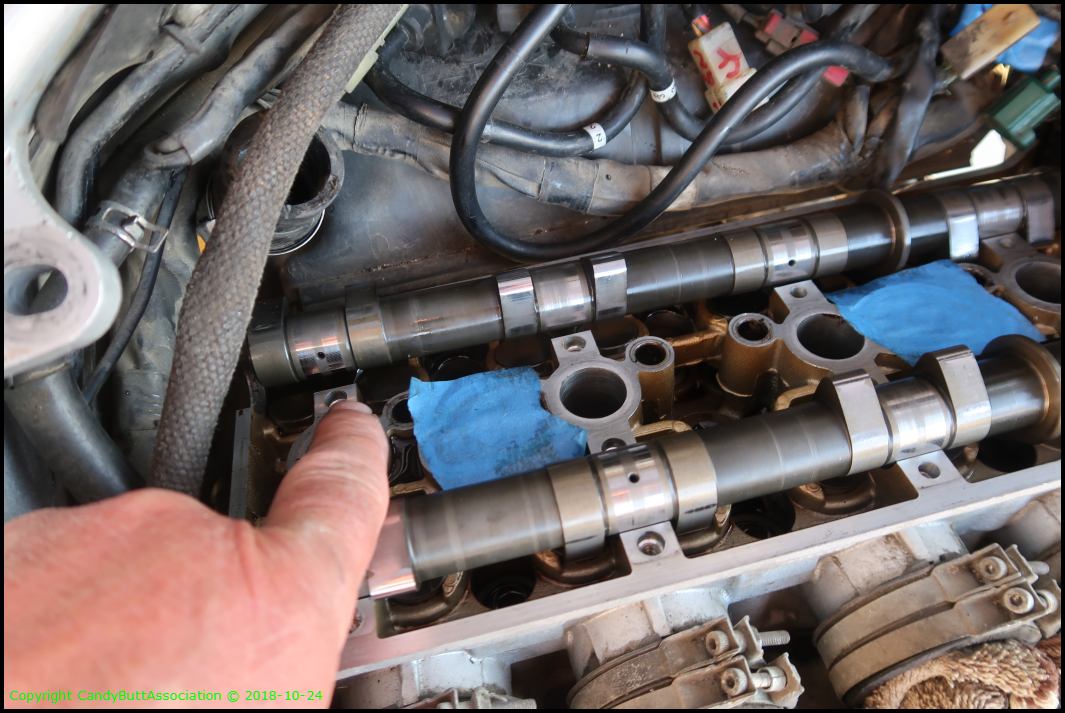

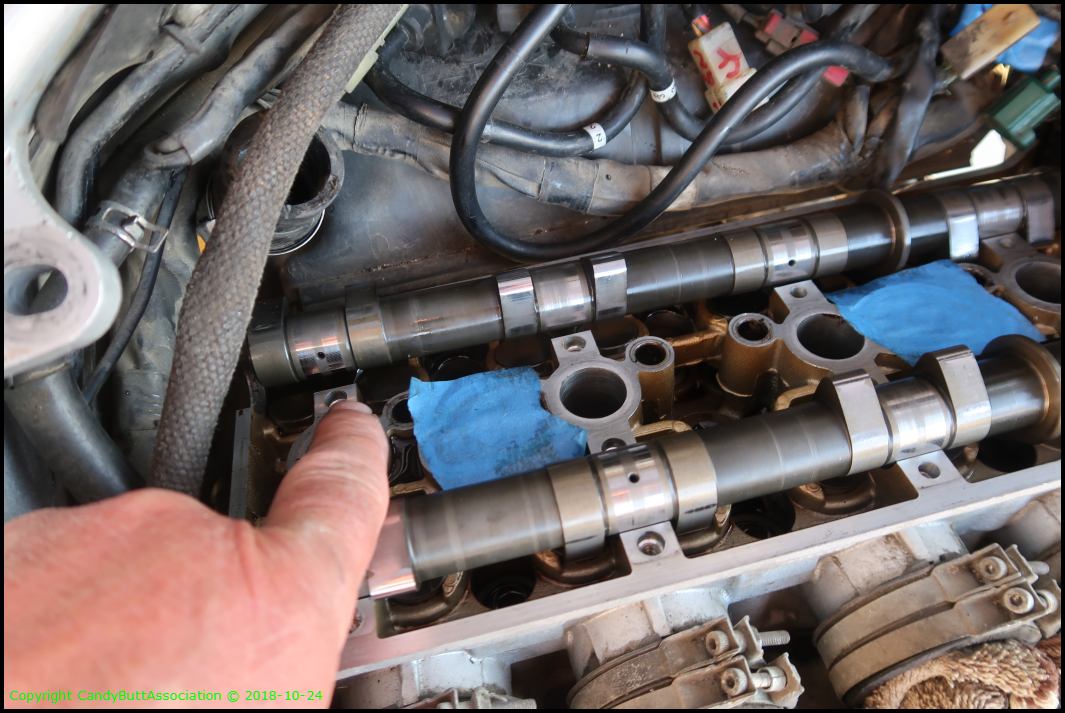

Incidentally i did have to change out one shim on the intake side since it was a little tight. I could not help myself since it was new to me to check the exhaust side torque since the intake side seemed really really torqued down and when i was re-torquing it seemed i was not tightening as hard as it was to loosen them, so i had to darn near use a breaker bar to loosen the exhaust side, then re-torque it to spec. Had a really hard time getting to the bolt on the far side if the cam that your finger is pointing to.

I followed this sequence when i did mine this spring and it's still running, however i might wait for wiser more experience folks to lend their expertise on the matter.I followed this sequence when i did mine this spring and it's still running, however i might wait for wiser more experience folks to lend their expertise on the matter.

Cheers..