Wow,splicing into the ECU harness looks a little scary, and restoring to original sometime down the road won't be a simple plug 'n play.

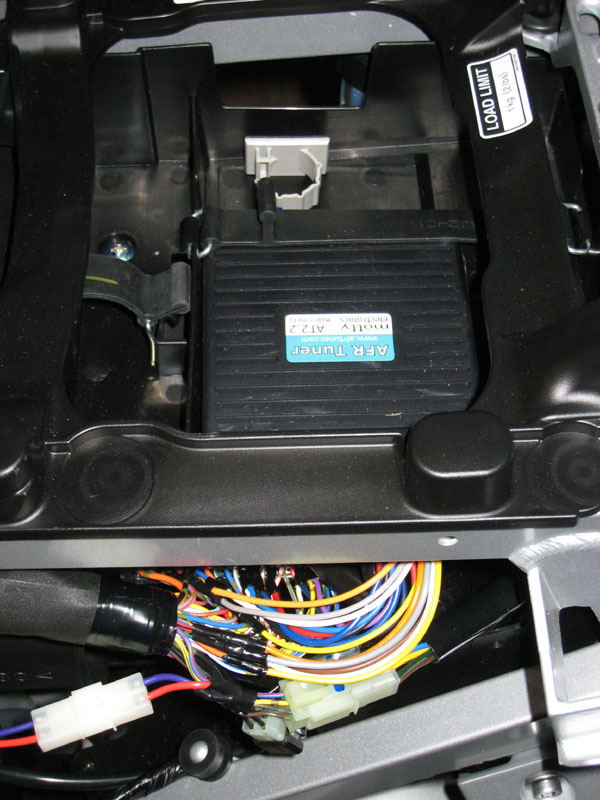

As long as you do the wiring correctly, the bike can be restored to original by plugging a small adapter into the Motty's wiring harness to pass the fuel injection signals through as usual. If you get a new bike someday, you can cap off the wiring harness on the old bike, order a new wiring harness for the new bike, and take the Motty unit itself to your new bike.

Curious,what does the Motty give you that something like a Power Commander does'nt?

Short answer: The Motty continuously tunes itself to account for changes to the bike and the environment, whereas the Power Commander must be tuned on a dyno.

Long answer follows...

A Power Commander only allows you to specify adjustments to the stock fuel injection amounts. The actual adjustment values must be tuned on a dyno to achieve the desired A/F ratios under different engine conditions (various combinations of throttle position and RPMs). The Power Commander then intercepts the fuel injection signals from the ECU and adjusts them by the amount specified for the current throttle position and RPMs. The adjustment values that are configured in the Power Commander become invalid any time something changes that affects the amount of airflow through the engine. Examples include changing exhaust, modifying air intake, and even more subtle and gradual changes such as seasonal temperature changes and an air filter becoming dirty. These all change the amount of air that goes int the cylinders. The ECU may make adjustments for this stuff, but how much of an adjustment is unknown. The Power Commander knows nothing about these changes at all and keeps on making the same fixed adjustments to whatever fuel injection signals come from the ECU. Any time you change your bike, you must get it re-tuned on a dyno. Your bike will only run perfectly as tuned when the environmental conditions are the same as they were in that dyno room.

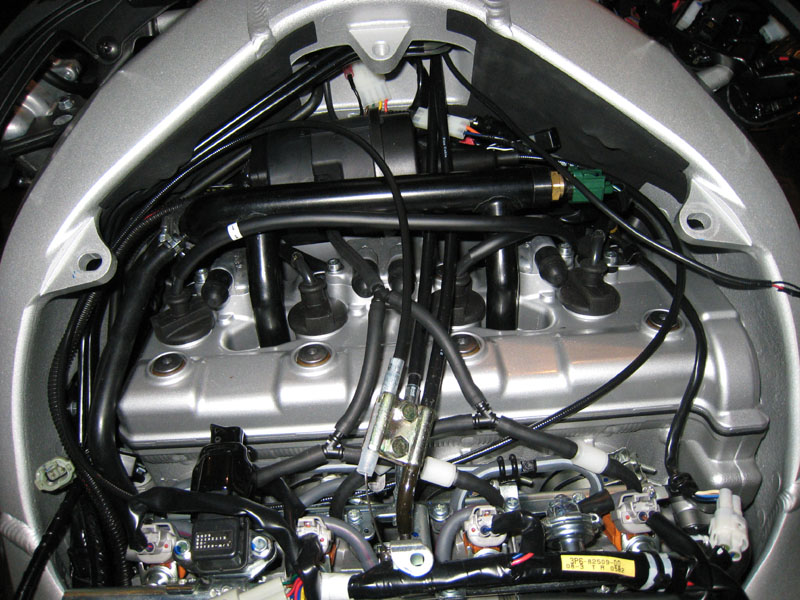

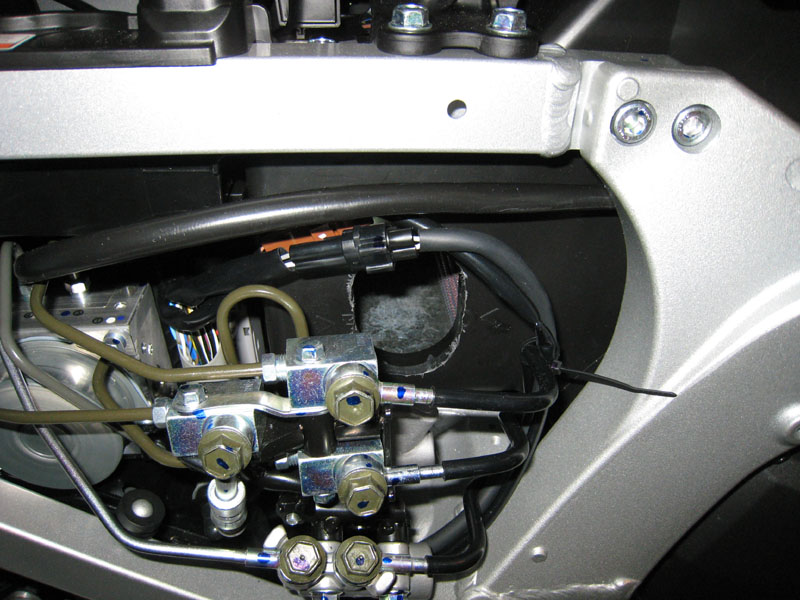

The Motty at its core is like a Power Commander - it has a table of fuel injection adjustments that it applies to intercepted ECU signals. However, the Motty also has a corresponding A/F ratio table that allows you to specify the exact A/F ratio that is desired for each throttle position and RPM combination. The Motty uses a wideband oxygen sensor mounted in the exhaust to measure that actual A/F ratio. It then continuously updates its fuel injection adjustments until the actual A/F ratio matches the desired A/F ratio. Never need to get it tuned on a dyno. It'll continuously tune itself as you ride.

The Motty also has a built-in data logger. This is useful for determining which portions of the map are used while cruising so that you can adjust the desired A/F ratio for better fuel economy in those areas.