I have removed the screws that are on the plastic piece in front of the seat that bolt into the tank. (to help get electric lines run under the seat) (Hex key 4mm) and now one of them won't screw go back in. How screwed am I? What do I do? Not real mechanical so could use some advice. Smart a__ comments are fine about the screw but would still like some actual ideas. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

screw replacement on tank

- Thread starter Havard

- Start date

Help Support Yamaha FJR Motorcycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Roadstar

Well-known member

The first time i took mine out , i had the same problem & found out i was at the wrong angle , so once i figured that out i have no problem. Another thing is loosin everything & try again. (hope it helps)

escapefjrtist

Searching for Dry Roads

I think Roadstar hit it on the head. Take the plastic surround off and see the angle necessary for the screws to start. Be very careful they aren't cross threaded...Then reassemble with the screws just snug, as there's not a whole lot of threads to screw into.

Good Luck.

--G

Good Luck.

--G

wfooshee

O, Woe is me!!

And when putting it back together (putting anything back together, actually) don't tighten any fasteners until all are at least started.

BobMercer

Well-known member

I've had the same experience, and I suspect that I've cross threaded the screws. Material seems to be pretty soft and vulnerable to cross threading. Gave some thought to using an appropriate sized tap, but it may cause more trouble.

Bob

Bob

$24.37

Fuel Tank Sticker Motorcycle Stickers for Yam&aha FJR1300 FJR 1300 Tank Pad Protector Decal Emblem Side Fairing Symbol Adventure

nanyangshixianpushangmaohanggerenduzi

$64.99

Edwards Oil Change Kit fits 2003-2020 Yamaha FJR1300 Sport Touring

Edwards Motorsports & RV's

$15.15

$21.95

Tough Headwear Balaclava Ski Mask - Winter Face Mask for Men & Women - Cold Weather Gear for Skiing, Snowboarding & Motorcycle Riding (Black)

Tough Outfitters

$22.09

$25.99

MOREOK Waterproof & Windproof -30°F Winter Gloves for Men/Women, 3M Thinsulate Thermal Gloves Touch Screen Warm Gloves for Skiing,Cycling,Motorcycle,Running-Black-L

MOREOK-US (Ships from USA)

$44.99

Real Time Industries Reflective Decals for Yamaha FJR1300 Gen 2 Fairing (Black - Silver Print)

Real Time Industries

$49.00

WILD HEART Waterproof Motorcycle Duffel Bag PVC500D With Rope Straps and Inner Pocket 40L 66L 100L for Kayaking, Camping, Boating,Motorcycle

ZHONGSHAN WILD FRUIT OUTDOOR

$127.99

$159.99

FLAVOR Men Brown Leather Motorcycle Jacket with Removable Hood (Large (US standard), Brown)

FLAVOR Leather

$22.09

$25.99

MOREOK Waterproof & Windproof -30°F Winter Gloves for Men/Women, 3M Thinsulate Thermal Gloves Touch Screen Warm Gloves for Skiing,Cycling,Motorcycle,Running-Black-XL

MOREOK-US (Ships from USA)

I think the threads are scewed up. I bought a Tap and Die kit last night and I think the screw and hole are 5MM and 09 thread. That is what it fit at Lowes on the size chart they have. I have never used a tap and Die set in my life. This sucks!

Know any fellow FJR riders in your area? If you were a little closer (okay, a LOT closer) I'd gladly come over and help.I think the threads are scewed up. I bought a Tap and Die kit last night and I think the screw and hole are 5MM and 09 thread. That is what it fit at Lowes on the size chart they have. I have never used a tap and Die set in my life. This sucks!

ionbeam

2 FUN

I was going to sit this one out, but...

Start screws by hand. If the screw is reluctant to start don't force it, the screw should go in easily. As mentioned previously, check for binding due to part alignment, don't tighten the screws until they are all in and started, and check for entry angle. If a thread does get buggered sometimes you get lucky and have access to the back side of the fastener; insert the screw from the back side and run it through and out the face side. This will essentially re-form the threads. This isn't ideal but it works.

If a screw is reluctant to start, turn it backwards(!) in the hole and you will almost always be able to feel a little click/pop where the screw threads back over the beginning of the lead-in threads in the nut or bolt hole. When you feel the little click try to start the screw again. If it still fails, reverse the screw again until you feel a click. This trick works best on fine threads and small screws but it can also help on coarse threads too.

[/too late]

What you want to do is 'Chase the Threads', not cut new ones like a tap is intended to do, though you can use a tap to do the job. Standard taps are actually designed to cut new threads rather than chase existing ones. Every time you use a standard tap to chase a set of bolt threads, the tap will also remove more of the existing threads. This reduces the overlap of the female threads. This reduced overlap can often lead to stripped threads unless you use less torque on the fastner.

Use a Tee handle and use lots of cutting oil. Line up the tap as best you can with the existing hole and threads. Turn the tap in a little, then back it out, then in a bit more and back it out some. This in/out action will allow the cutting oil to carry away any chips. If chips are allowed to build up the tap can break; taps are very hard but very brittle. If you break a tap in the hole your life will get a lot more difficult because you can't drill out a broken tap in most cases.

If the screw simply won't start you may be lucky and only need to dress the top turn of the threads to fix the lead-in thread. If you forced the screw in until it bound up then you will have to chase the entire hole.

May the force be with you

[too late]I think the threads are scewed up. I bought a Tap and Die kit...I have never used a tap and Die set in my life...

Start screws by hand. If the screw is reluctant to start don't force it, the screw should go in easily. As mentioned previously, check for binding due to part alignment, don't tighten the screws until they are all in and started, and check for entry angle. If a thread does get buggered sometimes you get lucky and have access to the back side of the fastener; insert the screw from the back side and run it through and out the face side. This will essentially re-form the threads. This isn't ideal but it works.

If a screw is reluctant to start, turn it backwards(!) in the hole and you will almost always be able to feel a little click/pop where the screw threads back over the beginning of the lead-in threads in the nut or bolt hole. When you feel the little click try to start the screw again. If it still fails, reverse the screw again until you feel a click. This trick works best on fine threads and small screws but it can also help on coarse threads too.

[/too late]

What you want to do is 'Chase the Threads', not cut new ones like a tap is intended to do, though you can use a tap to do the job. Standard taps are actually designed to cut new threads rather than chase existing ones. Every time you use a standard tap to chase a set of bolt threads, the tap will also remove more of the existing threads. This reduces the overlap of the female threads. This reduced overlap can often lead to stripped threads unless you use less torque on the fastner.

Use a Tee handle and use lots of cutting oil. Line up the tap as best you can with the existing hole and threads. Turn the tap in a little, then back it out, then in a bit more and back it out some. This in/out action will allow the cutting oil to carry away any chips. If chips are allowed to build up the tap can break; taps are very hard but very brittle. If you break a tap in the hole your life will get a lot more difficult because you can't drill out a broken tap in most cases.

If the screw simply won't start you may be lucky and only need to dress the top turn of the threads to fix the lead-in thread. If you forced the screw in until it bound up then you will have to chase the entire hole.

May the force be with you

Last edited by a moderator:

mcatrophy

Privileged to ride a 2018 FJR1300AS

As usual, all very good advice.I was going to sit this one out, but...

...

What you want to do is 'Chase the Threads', not cut new ones like a tap is intended to do, though you can use a tap to do the job. Standard taps are actually designed to cut new threads rather than chase existing ones.

...

May the force be with you

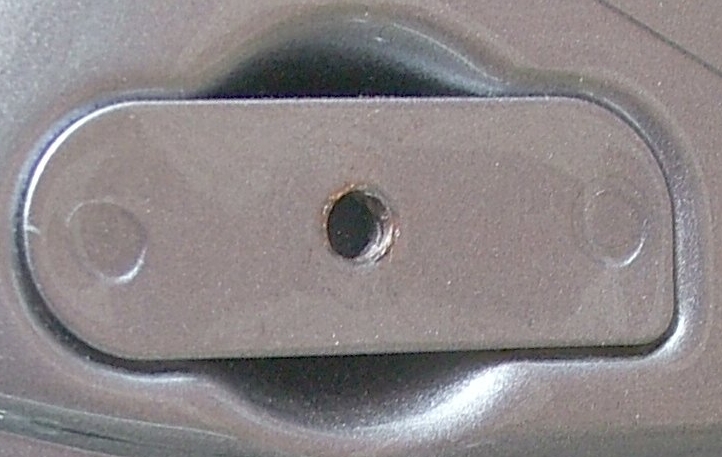

It's worth remembering that this particular thread is perhaps the worst engineered one on the bike.

(Click on image for larger view)

It's cut into a thin piece of metal strip, and there's not a lot of room behind it for a tap to go in. I'd suggest using the final tap from a set designed to tap deep into a blind hole.

{edited to add blow-up]

Last edited by a moderator:

ionbeam

2 FUN

Wow, another Gen II feature I don't have on my Gen I

Fortunately this cruddy setup is for a cosmetic piece and does not require structural amounts of torque.

I don't know what the access is like behind this spot welded sheet steel piece, but if things go really bad here are a couple of ideas. Good or not, or applicable I dunno. Doomsday solutions: Clickable link pixs

Is there room to add a clip nut, similar the ones around the front faring?

Probably the best solution would be a self clinching nut. It would be slipped in from the back side if there is room, then the serrated ring would be drawn into the now stripped hole. Self clinching nuts like this one from PEM work real good and will neither spin or strip.

Self-clinching nuts are installed by placing them in properly sized holes in sheets and applying a parallel squeezing force to the head of the nut. The sheet metal surrounding the head cold flows into an undercut thereby making the fastener an integral part of the sheet. A serrated clinching ring prevents the fastener from rotating after installation.

Either of these solutions should last the life of the bike. Perhaps these ideas will inspire some other similar solutions.

Fortunately this cruddy setup is for a cosmetic piece and does not require structural amounts of torque.

I don't know what the access is like behind this spot welded sheet steel piece, but if things go really bad here are a couple of ideas. Good or not, or applicable I dunno. Doomsday solutions: Clickable link pixs

Is there room to add a clip nut, similar the ones around the front faring?

Probably the best solution would be a self clinching nut. It would be slipped in from the back side if there is room, then the serrated ring would be drawn into the now stripped hole. Self clinching nuts like this one from PEM work real good and will neither spin or strip.

Self-clinching nuts are installed by placing them in properly sized holes in sheets and applying a parallel squeezing force to the head of the nut. The sheet metal surrounding the head cold flows into an undercut thereby making the fastener an integral part of the sheet. A serrated clinching ring prevents the fastener from rotating after installation.

Either of these solutions should last the life of the bike. Perhaps these ideas will inspire some other similar solutions.

Last edited by a moderator:

Grumpy

Well-known member

Agreed! So far, only the front forks and brakes appear to be an improvement over my '03 Gen I

When you talk chasing the thread are you talking about using the tap and die or is there another magic tool that I am not aware of? The clips may be the next option that I go with. Will try to tap tonight and see what happens.. WISH ME LUCK!

Thanks for the ideas folks.

Anyone else think that Tap and Die is not the most encouraging name. Just an observation.

Thanks for the ideas folks.

Anyone else think that Tap and Die is not the most encouraging name. Just an observation.

UPDATE:::

I think it will work. tapped and died both hole and screw and they now go together. Will find out when I am actually done wiring and put it back together to see if it holds. Thanks for all the help everyone. Moral support sometimes helps.

Now to get the Fuzeblock hooked up. The Farkeling never ends!

I think it will work. tapped and died both hole and screw and they now go together. Will find out when I am actually done wiring and put it back together to see if it holds. Thanks for all the help everyone. Moral support sometimes helps.

Now to get the Fuzeblock hooked up. The Farkeling never ends!

After looking at the last pics, I'd seriously consider drilling the holes out and changing to a plastic fastener as used on other parts of the bike where you have a push in center piece to release, then pop it back out to re-insert and push it flush to lock. This type of trim piece has no real need for a threaded fastener and you'd never need to worry about damaged threads again.

To answer your question, yes there is a tool called a re-threading or thread restoring tap. LINK They are not designed to cut new threads. These work very well in aluminum or mild steel, but not in hardened steel. The idea is to re-form the threads w/o removing material. Not ideal for the sheet metal application here, but would have probably done the job. There just isn't much material there to work with in this case.

They also make re-threading dies, btw.

To answer your question, yes there is a tool called a re-threading or thread restoring tap. LINK They are not designed to cut new threads. These work very well in aluminum or mild steel, but not in hardened steel. The idea is to re-form the threads w/o removing material. Not ideal for the sheet metal application here, but would have probably done the job. There just isn't much material there to work with in this case.

They also make re-threading dies, btw.

dcarver

Well-known member

One of mine came back stripped after stealership job. IIRC, the plastic push rivets won't work due to lack of hole dept. It's been too long ago that I looked at. Since mine is covered by the seat I just left it empty.

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 10

- Views

- 942

- Replies

- 33

- Views

- 3K