OK, well... I received my COS last Friday. It is a Char Broil American Gourmet 300 series offset smoker. It is pretty small in size, but I should be able to do some decent sized pieces of meat. The smoking chamber (larger cylinder) is 24'" long and about 12" wide, so whole chickens won't be a problem, but, probably no whole turkeys.

Put it together and started the seasoning process per the instructions. Just built a charcoal briquette fire in the firebox on the provided grate and tossed on a few pieces of wood for effect, and to get things properly "seasoned" in the smoking chamber.

During the burn-in, I immediately noticed a few problems with this smoker in its stock form. The biggest downfall is that the temperature gradient in the smoking chamber is way too big. The left side nearest the firebox would be almost 300 degrees and the right side is only 200 or less. Also, maintaining any sort of steady heat would seem to be a problem as the temperature in the smoking chamber would rise very quickly to higher than desired.

Time to farkle!

(disclaimer: Yes, I am a tinkerer. I like to mess around and design or redesign things on the fly. I just get an idea and I try to cob something together using readily available materials)

First challenge was to get more fuel into the firebox for a steadier burn. Just throwing charcoal inside the sheet metal firebox might get the job done, but the air flow to the charcoal wouldn't be good, and the sheet metal box would erode quickly. So I got a 1' x 2' piece of expanded metal (cost ~ $10) and fabbed up a screen charcoal box to go inside. This will provide a mini-Minion method burn and should extend the time between fuel feedings somewhat.

The box is 8"x8" and 6" high. To make this box from the one sheet of expanded metal take the 24" long sheet and cut 8" off one end, then cut the remaining 16" lengthwise into two 6" x 16" pieces. Bend the two 16" pieces into right angles and I used pieces of coat hanger to join the ends to form the box. You could just drop the formed box on top of the stock wire grate, but I opted to bend up the ends of that extra 8" piece, place that on top of the grate and just drop the box on top of that before filling it. Still have plenty of access for adding fuel through the door.

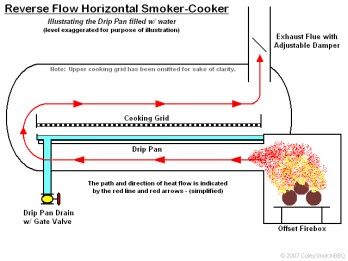

Next, I decided that, in order to make the smoking chamber temperature more uniform, I would want to convert the smoker into a reverse flow smoker. Here's the idea...

Normally the smoke and heat from the firebox enter the smoking chamber from the lower left side and just waft across the smoking chamber on the way over to the chimney / exhaust on the right. So the left side of the smoking chamber is too hot and the right side is too cool. To make a reverse flow you just need to relocate the chimney to the firebox side of the smoking chamber and then build a baffle to make the smoke travel all the way across the bottom of the chamber before allowing it to rise up to the meat on the grilles in the upper half of the chamber.

Here's a diagram of a reverse flow smoker (this would be looking at my smoker from behind)

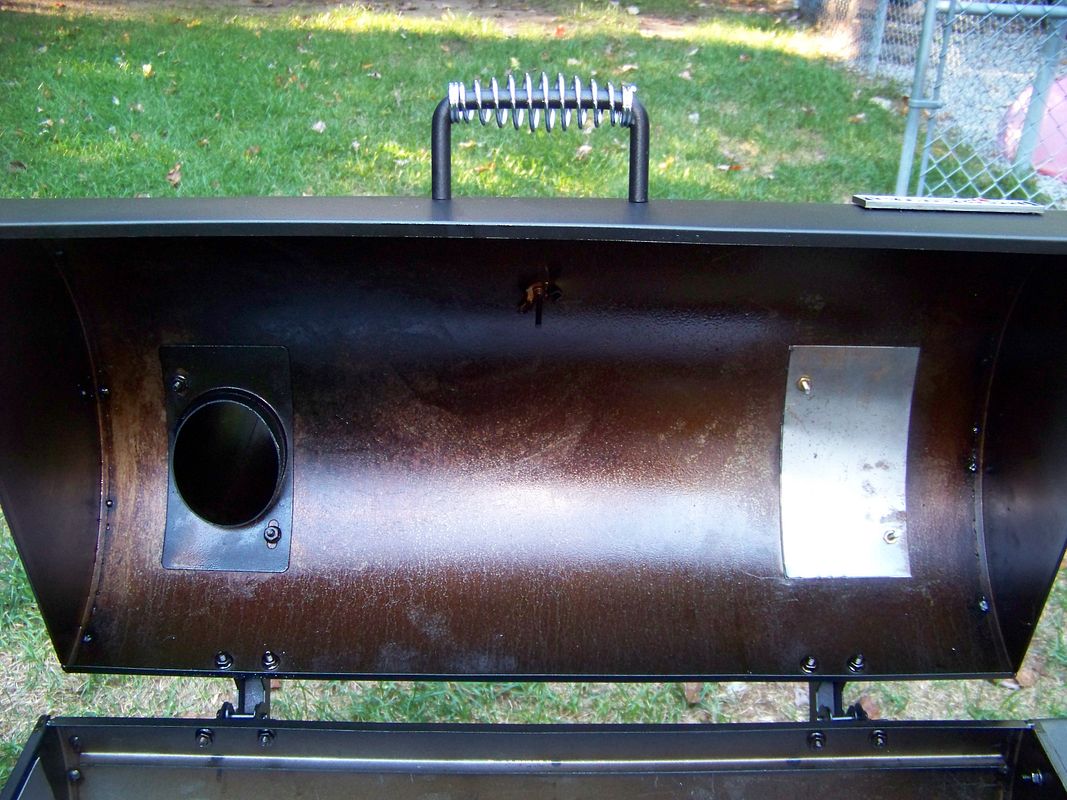

A 2' long x 9 1/4" piece of sheet metal forms the baffle plate, bent at the end and fastened to the end of the chamber using the screws that join the two chambers, blocks off the upper part of the hole between the firebox and smoke chamber.

View from inside the firebox shows that a little more than half of that communication hole between chambers is now blocked off. Smoke and heat must go under the baffle plate.

Cut a new oval hole for the chimney on the opposite end of the smoke chamber lid (patterned after the original one) and mounted the chimney over there, then made a sheet metal patch plate for the original hole.

Fired up the pit with the new mods to get all the new metal "seasoned" and to test out the mods.

I noticed a huge improvement in temperature control-ability. I am easily able to maintain a uniform 225-250 degrees in the smoke chamber and the temperature across the chamber is much more uniform. The baffle plate gets pretty warm, especially on the left side nearer the firebox, which will add radiant heat from below on the (now) cooler side of the smoke chamber. I'll be adding a rectangular water / drip pan on top of the baffle plate when in use to act as a heat sink and also give off some moisture to the smoke.

I have a few mods left to make to get this thing really ready to cook. I still need to extend the chimney pipe on the inside downward to nearer the grille height. This will help capture the hotter smoke in the upper part of the chamber rather than allowing it to escape, and vent the cooler smoke at the grille level. This is a common mod for any smoker.

I also plan on buying some high temp sealant/cement of some kind (maybe just use JB Weld) and plug up most of the leaks in the smoke chamber. Air leaks in the firebox are no big deal. You have to have air in there to burn the charcoal and wood anyway. But air leaks in the smoke chamber are causing it to cool too much and require more charcoal and wood to be burnt. I'll also be making some sort of a gasket for the smoke chamber lid, for the same reason.

I haven't cooked a thing on this little smoker, but I'm already having fun messing around with it.

![Decrum Motorcycle Jacket Men - Mens Leather Jacket | [1100065] Austin Brown, XL](https://m.media-amazon.com/images/I/41HqZSRj6LL._SL500_.jpg)