OK, time to resurrect this thread instead of starting a new one...

I just rec'd my Spieglers (ABS kit) from Gary. BTW, he was awesome to deal with, and the stuff came in record time, exactly (I think) as I asked.

Here are a few questions for those who installed this kit. While the instructions on FJR1300.info help, they are far from complete and seriously lack photos.

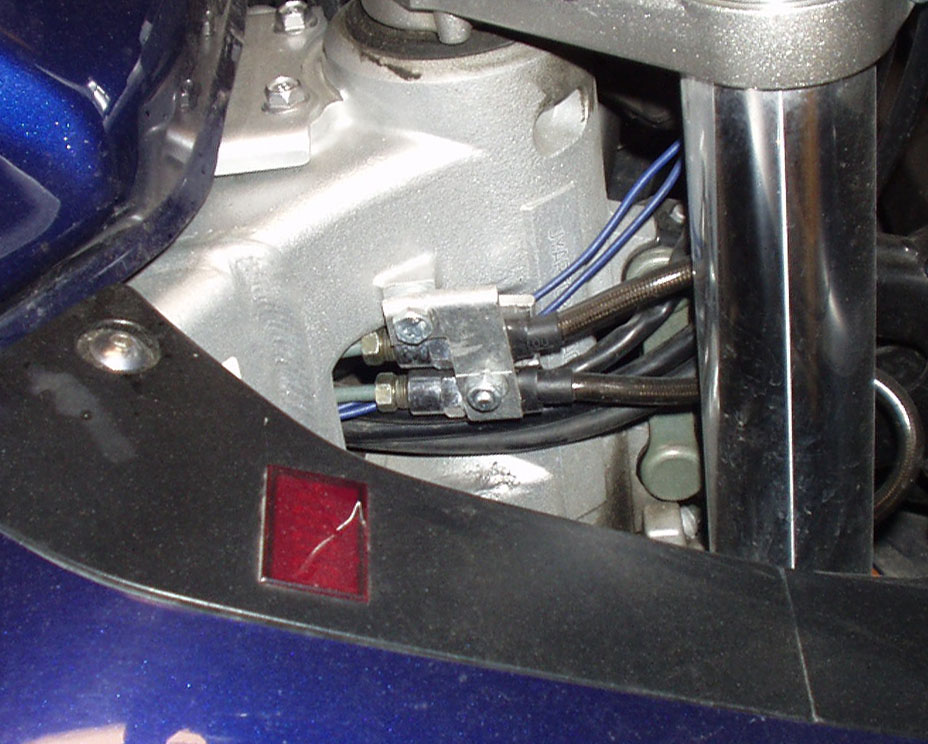

1. I asked for all banjo bolts and rec'd a total of six. One is a double M10 for the 2-way manifold, one is a single M10 for the 2-way manifold. That leaves the four standard thread single banjo bolts. Where do these go? Assuming I re-use the bolts at the ABS pump, there would be two master cylinders and three calipers, for a total of five, so I am one short. Obviously, I will use all three calipers, so which master cylinder gets to keep its original bolt? The rear or front?

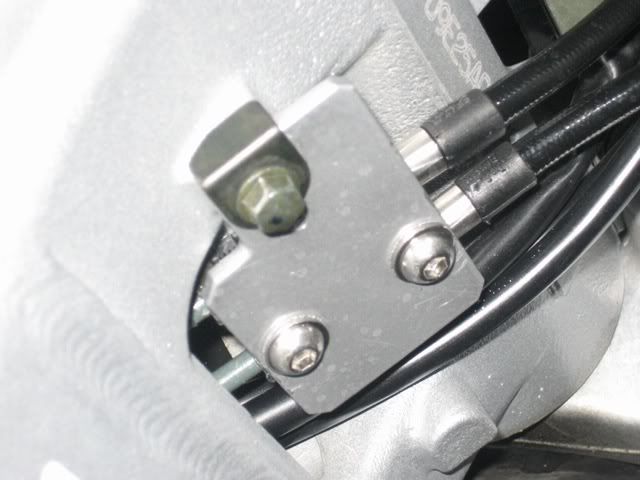

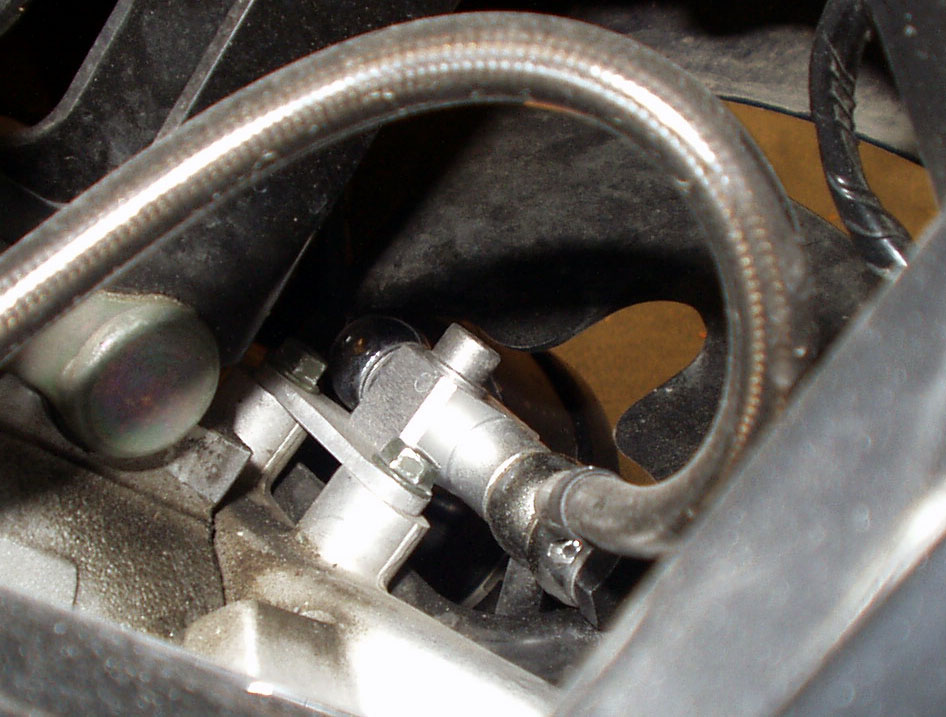

2. How the frig is the two-way manifold configured and mounted? A picture with the line positions would have been nice. I assume the feed from the hard line and the right caliper go on one side, the left caliper is on the other, but still, do they expect us to be psychic? The mount bracket looks like something Helen Keller whipped up in her spare time, too. I cannot in good conscience put this POS on my ride.

3. I count 12 banjos, so with a crush washer on each side, I should have 24. For some reason, the line position sheet indicates 23. WTF? Which banjo gets screwed? Is it the interface between the double banjo? Luckily, they actually put in 26, so when I wreck one I'll be backed up...

4. If anyone has more detailed instructions, or even better yet, some photos, I would gladly repay you somehow.

Thanks in advance!

-BD

![fjackets Real Lambskin Leather Biker Jacket — Quilted Cafe Racer Zip Up Moto Leather Jackets For Men | [1100085] Johnson Brown, XL](https://m.media-amazon.com/images/I/41I7Pm1f+vL._SL500_.jpg)