bluesdog

Well-known member

iirc, it took @ 3 or so sessions before I got mine synched up nicely. Coming up to +53K km now, and it pulls turbine smooth and strong to redline, and I'm still too chicken to WOT in first.

Well you have to understand that the inner workings of what is going on is new to me. If this was normally aspirated, I may not be as out to lunch. Don't forget, you did say "It's much better for folks to be actually thinking (you remember how to do that?) about what it is they are doing, or adjusting, or attempting to do, and consider the ramifications and consequences, rather than just blindly going out and following procedures from some knucklehead chump that says: Hey This is the next best thing since sliced bread."Dude, you are over-thinking this thing way too much. And imagining things too, no doubt. Obsession is not a good thing.

Adjusting the 3rd cylinder screw is no different than adjusting the other three. It didn't cause your engine to sack out. What the absolute reading is on your vacuum gauge is not significant. You have no ability whatsoever to change that.

Take the ride and enjoy it and stop worrying yourself about nothing.

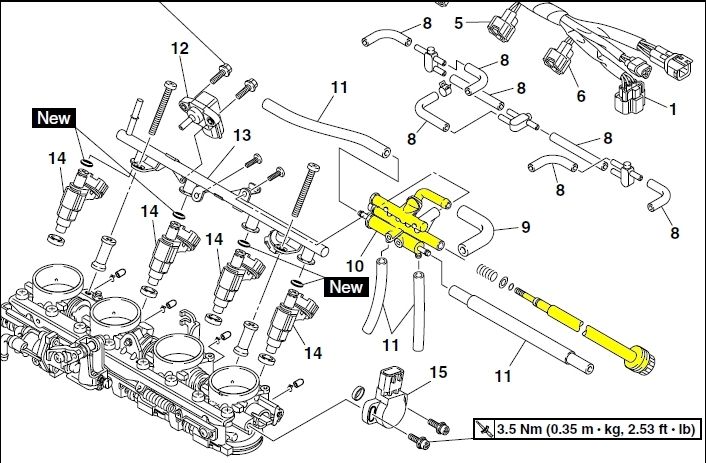

Let me start off by describing the linkage adjustment. The four throttle body plates are on independent shafts that are each connected through the screw adjustable mechanism. The throttle cable is on the #3 shaft, and on 1st Gens that is where the mechanical idle adjuster is, which is just a screw adjustable stop. 2nd Gens have an additional air bypass circuit for for idle adjusting (more on that later)You state to sync the 2-3 adjustments first but how do you determine whether you should adjust the 2-3 to match the other two rather than adjust the other two to match the 2-3?

No, after everything is adjusted perfectly the butterfly valves are not fully closed at idle. There is actually a secondary screw stop on each TB (one that we never touch) that ensures the valves do not close fully. The air required for the bike to idle is a sum of the air passing through the slightly open butterfly and any bypass air (air screw and idle adjust).- I fail to understand what is really happening mechanically when you adjust each throttle plate screw. I would presume youre just adjusting the angle of the butterfly valve and with this set up, youre adjusting two at a time. Is this correct? If so, at idle aren't all the valves supposed to be fully closed? Why cant we just back off the screws (or turn them all the way in - whichever the case may be) and then reverse direction until there the movement makes a difference? You'd know then that the valves are all fully closed.

As mentioned above, the Gen 2 warm idle adjuster is an adjustable air bypass. Here's a thousand words to describe it below:In your Gen II procedure, you suggest to adjust the idle first then close off all the bleed screws ( I thought someone else mentioned to try and bring the idle screw all the way out and hold idle using the throttle - I'm not sure which is best) but there is a problem with this as you will have to shut off the bike to adjust the 2-3 and it would be near impossible to get the same throttle when you re-start.

You have been thinking!Finally, and this is a bit outside the box from what we are doing, but correct me where I am wrong: The throttle body valves open in order to allow more air in. In a normally aspirated engine, the increase air flow creates a low pressure and sucks in more fuel. But in a fuel injected engine, isn't that fuel metered depending on what the throttle position sensor says? And, isn't the TPS calibrated to a position set of one of the butterfly valves? In other words, by adjusting the valves positions, are we not in effect screwing up that calibration thereby changing the amount of fuel that is metered for a certain amount of air (throttle position)?

Another great question. The manufacturer either sets the relative throttle positions mechanically during assembly, or maybe on a flow bench prior to installing it on the bike, for precise alignment of the throttle plates. They say that they should never need to be mechanically adjusted after that, and that you should only adjust the air screws for balance at idle. But we owners have noticed that this does not always result in the least possible vibration at higher rpms.Can someone explain to me the difference between adjusting throttle valves and the bleed air and why does the shop manual state not to ever adjust the former? Why then are they there?

Now here is what I don't understand: why bother screwing around with the bleed screws at all? why not leave them closed and adjust the master idle until I get 1100?

Haven't had a of opportunity to review this until today. Thanks for taking the time to respond in detail and your explanations certainly clear up most of my questions. i particularly benefited from how you described how the the throttle body plates and adjusters work.Hopefully some of the above helps you understand what's going on a bit better.