wfooshee

O, Woe is me!!

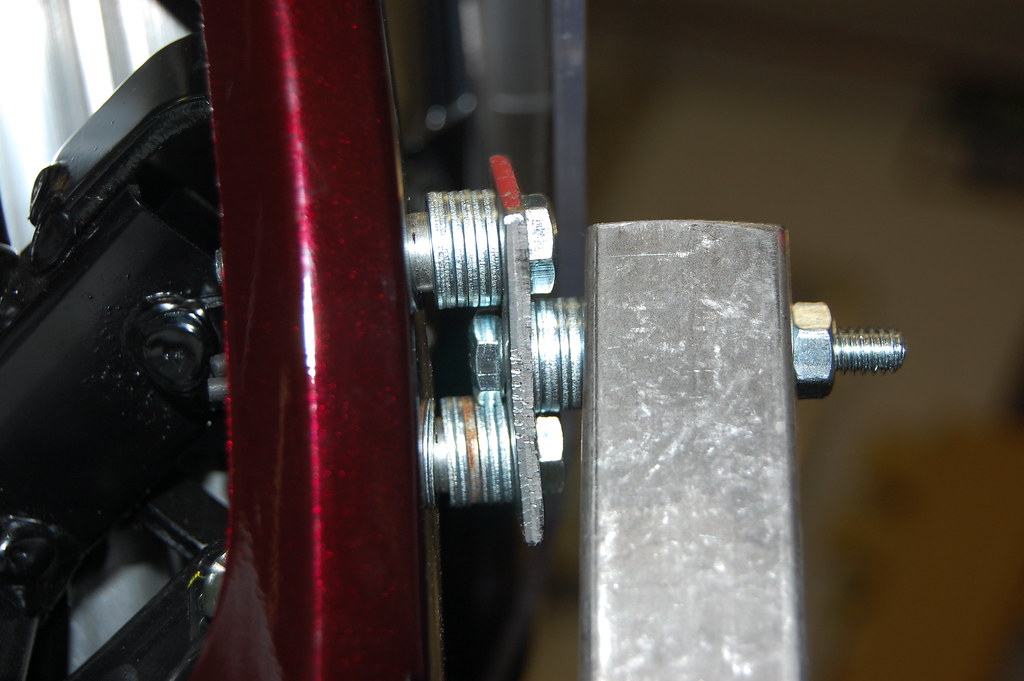

I've had to "adjust" mine, too, and it's not hard, but the adjust was for the mirror being tilted upward after a lowside, not because it sits 1/8 inch too far rearward. That said, a very slight tweak of the plate making the mirror tilt toward the front of the bike (i.e. raising the rear mount hole) would have the effect of moving that base forward slightly. Maybe enough.

The front stay is steel. Magnets adhere to it. Still very easy to bend.

The point above about the windshield being perhaps not exactly symmetrical is a good one, too, and one I didn't consider.

The front stay is steel. Magnets adhere to it. Still very easy to bend.

The point above about the windshield being perhaps not exactly symmetrical is a good one, too, and one I didn't consider.