TomInPA

Well-known member

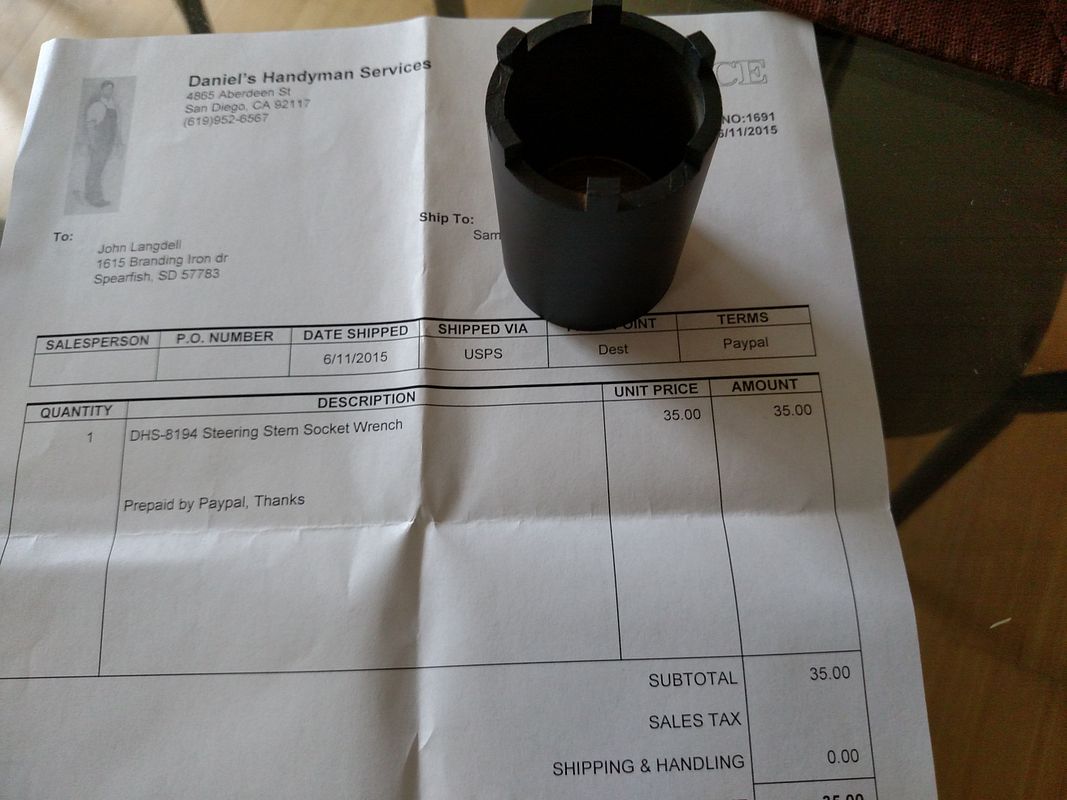

I didn't get Roy's socket when he was making them, and the Yamaha YU-33975 Spanner is pretty scarce. Lots of knock-offs on Ebay, and I'll consider those if someone here doesn't have one they are done with. Anyone with experience with these $29-$32 spanners?

I have developed a pretty distinct click in the steering stem and need to get this done in the next week or so. I need a 36mm socket and spanner. I will settle for either/or.

I have developed a pretty distinct click in the steering stem and need to get this done in the next week or so. I need a 36mm socket and spanner. I will settle for either/or.