Thanks, yes I do have a service manual. First thing I did was drop the fork a little so I could get a socket on it without having to mess with the handlebars.

Thanks Mcrider007 And FJR4me for confirming that the socket I need to make that long extension tool is indeed a 26mm. That is one hard socket to find. I thought surely Sears or Harbor Freight would have it, but nope. Gotta keep searching. I'll try Auto Zone tomorrow. So far, none of my friends have that odd duck socket. Oh well. And concerning the advice given by Fred (thank you) about NOT needing this special tool, I'm going to make one anyway as I intend to help others do this in the future and it would be nice to have one around just in case. Besides, my buddy Ted from church is itching to do this welding project for me, so I'm going to go ahead with it. Rummaging around his garage, he already found a 16 inch length of 3/4 inch pipe. He'll have this special tool whipped up in no time, all I need is that socket.

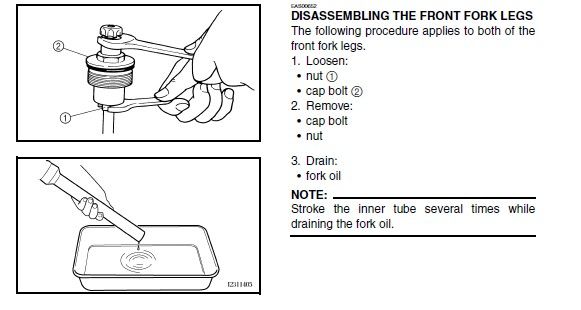

So anyway, here's a few pics of my progress:

First we removed the fender and wheel and the two bolts from the calipers and used some wire to hang them from the mirrors;

Once the calipers were supported, I loosened up the two pinch bolts in the lower triple tree: contrary to what the manual says, you don't have to remove anything to do this. The allen wrench fits up in there just fine.

Next, I loosened the top bolt and dropped each fork...

about 3 inches, and then re-tightened one of the bolts in the lower triple tree. With the fork held firm, I loosened the 24mm cap nut on top of the fork. Doing it this way enables me to leave the handlebars on. There's no way to get that socket in there with the handlebars in the way... without dropping the fork tube a little. Note that quality Harbor Freight 24mm impact socket in dazzling flat black...

Then I loosened the bolt again and slid the fork out of the bike:

Then I clamped it in the vice

and attempted to loosen this rascal. But it was NO GO trying to use the open end of my 17mm wrech... too tight.

First I gotta get that knob off the top so I can get my box end 17mm past it...

So after waiting a while and getting some more advice from the forum, I grabbed my 14 and 17mm wrenches and gave it a good twist:

It took a little more torque than I thought it would, but it popped loose just fine:

The cap assy screwed off easily:

But the nut wouldn't come loose. So I grabbed the threads with my pliers and a couple strips of scrap wood (to protect them),

Which allowed me to unscrew the nut easily:

Then I slid this spacer tubie thingie out...

And set everything aside to keep it in order:

Though it's hard to see the allen headed bolt up inside the bottom of the fork thanks to the lack of good lighting in this picture, that'll be the next thing I take loose once I finish taking the fork apart and draining the oil out... and I complete the special tool with its 26mm socket to hold the other end. I'm guessing this is the process that can be done just as easily most of the time according to FredW's advice about using the spring tension of a re-assembled fork to hold the rest of the assy in place RATHER than requiring any special tools.

We'll try to tackle some more of the project tomorrow. I'm working on this alone and when I've got the umphh to get out there after a long day at work each night. But I do have great lighting in the workshop and I can't complain about the 65 degree temps out there each night. Gotta love Florida this time of year.

Tomorrow I'll be pulling the large diameter washer out once I find my magnetic pick-up tool and begin disassembling this thing. Not sure of exactly what I'm doing, but it's going well thus far.

EDIT: I FOUND THE MAGNETIC PICK UP TOOL, BUT IT WAS NO MATCH FOR THAT WASHER. IT WOULDN'T COME OFF. I FOUND OUT WHY LATER ON IN THIS THREAD...

Gary

darksider #44