OK - I'm trying to swap out the new pumpkin and I've got 2 problems.

1. I can't seperate the drive shaft from the broken pumpkin.

Here's a picture of the new pumpkin:

Those splines are way larger than the drive shaft:

I tried removing the circlip and pulling on the drive shaft, but it won't budge.

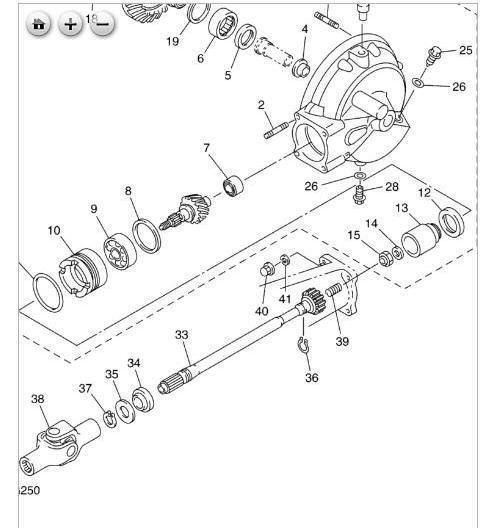

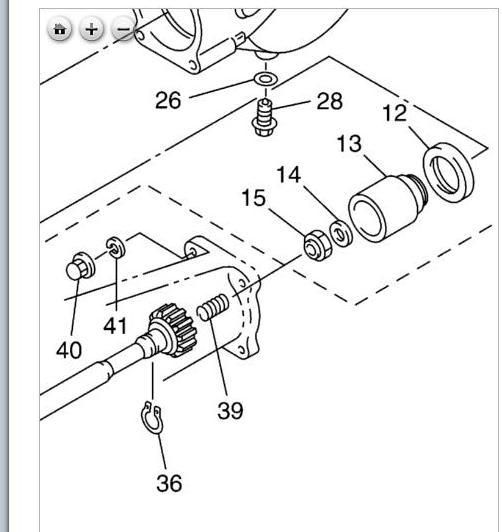

Here's a picture of the parts breakdown:

And a much closer shot:

There does not appear to be any kind of dust seal or other part in this breakdown.

Now here's a picture of a used driveshaft on ebay:

I can see the dust seal on my old pumpkin. There does not appear to be any other clip holding that dust seal in. Maybe I just need to pull on it harder to get it out??? Maybe the assembly was heated on there from running the bike with no rear end oil? What gives here?

2. Not really a problem, but I need to verify that the axle collar just slides in there:

As I was trying to figure out problem #1, when I rolled the broken pumpkin over, the collar fell out.

It will only go in one way, but when i stick it back in there, it doesn't seem to fit right.

It is loose (little slop between the collar and the pumpkin) and it doesn't sit all the way down. I verified with my dial caliper that the collar cannot go into the axle guide on the outside end of the pumpkin (the side where the axle nut washer and nut goes). The collar is substantially larger in diameter than the axle guide. Maybe it just sits in there, but it just doesn't look right. I think the purpose of the collar is to provide support laterally (along the plane of the axle. The larger shoulder on the inside pushes against the wheel bearing. and the small shoulder pushes against the axle guide. The nut just squeezes everything against each other. I mean the axle will center that collar and once that is done, the collar can't move radially I suppose. If I'm right (the collar takes no radial load), then I guess it just slips in there loosely but I just wanted to verify it.

Any help would be appreciated.