You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4 Lessons - Costly, But Priceless

- Thread starter hppants

- Start date

Help Support Yamaha FJR Motorcycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Top_Speed1

Panama Canal Crosser

I think a simple swapout with your good buddy Andrew is in order!. Get out a bottle of scotch, tell RFH that you want to celebrate 'All Saints Day' (but, I'm thinking that may be a holloweener day after dealio however)...

In the morning.... wallah!

Seriously, that sucks , and for peace of mind, jus do it. Leave the final drive problems to the R1200 klan

, and for peace of mind, jus do it. Leave the final drive problems to the R1200 klan

In the morning.... wallah!

Seriously, that sucks

Redfish Hunter

Gone Fishing

Just so you know RFH's final drive may not be moving very far but it does move almost every day. On sunny days there are sometimes 3 other bikes parked next to mine. On rainy days only my FJR is in the parking lot.

It is worth noting that my final drive and Dad's final drive will be in Arkansas by Sunday afternoon and will be staying there for a few days. Perhaps I should check the drain plugs before we leave.

I did think about this whole situation this morning when I was changing the oil in Dad's FJR. I made absolutely certain the drain plug was torqued.

It is worth noting that my final drive and Dad's final drive will be in Arkansas by Sunday afternoon and will be staying there for a few days. Perhaps I should check the drain plugs before we leave.

I did think about this whole situation this morning when I was changing the oil in Dad's FJR. I made absolutely certain the drain plug was torqued.

bergmen

Well-known member

...including the replacement of the rear end differential fluid...

Fingernails on a blackboard.

Just sayin'.

Dan

Fingernails on a blackboard.

Just sayin'.

Dan

Last edited by a moderator:

Uncle Hud

Just another blob of protoplasm using up your oxyg

(original post deleted -- 'cause I missed the point. But thanks for the 'like', WheatonFJR!)

I am an *******. And an idiot. Dangerous combination.

I am an *******. And an idiot. Dangerous combination.

Last edited by a moderator:

Spud

Well-known member

You may want to see if these guys will buy your final drive:

https://rmsportmax.com/gateway.html

It's the company that does final drive gear swaps for the FJR and other bikes and they take core exchanges. They may want it....

https://rmsportmax.com/gateway.html

It's the company that does final drive gear swaps for the FJR and other bikes and they take core exchanges. They may want it....

$24.37

Fuel Tank Sticker Motorcycle Stickers for Yam&aha FJR1300 FJR 1300 Tank Pad Protector Decal Emblem Side Fairing Symbol Adventure

nanyangshixianpushangmaohanggerenduzi

$89.45

No Cutting Motorcycle Frame Slider Anti-collision Drop For Yamaha FJR1300 FJR 1300 2006-2011 motorcycle crash pad(Carbon Fiber Look)

dengzhoushijiushuncaishangmaoyouxiangongsi

$159.99

FLAVOR Men Brown Leather Motorcycle Jacket with Removable Hood (Large (US standard), Brown)

FLAVOR Leather

$19.99

MOREOK Winter Gloves -10°F 3M Thinsulate Warm Gloves Bike Gloves Cycling Gloves for Driving/Cycling/Running/Hiking-Black-L

MOREOK-US (Ships from USA)

$64.99

Edwards Oil Change Kit fits 2003-2020 Yamaha FJR1300 Sport Touring

Edwards Motorsports & RV's

$79.95

Harley-Davidson Water-Resistant Travel Hybrid Duffel Bag/Backpack - Black

Wisconsin Harley-Davidson

$98.16

25-1775 Replacement for All Balls Wheel Bearing Kit (25-1775) for Yamaha FJR1300 03-16 FJR1300ES 14-18

Otisdelilah Auction

When I first got my gen 2 it had 40,000 miles on it and came with a comprehensive service history from a major Yamaha dealer which turned out to be, lets just say a far more impressive pile of paper than any evidence of their efforts on the bike. I drained the pumpkin and I genuinely believe it was the original oil, I'll not try to describe it! There was plenty of grey metallic dust in it with some small metal flakes and I thought it was toast. It took 3 or 4 flushes before it ran clean. That was 30,000 miles ago. I change it every 5000 and its always clean. I think these parts are tough and I'm sure you would have been fine. But, it's your decision and your money.

infrared

Well-known member

- Joined

- Aug 11, 2013

- Messages

- 374

- Reaction score

- 173

Hhpants,Infared - I'm intrigued. Do you cross drill your drain plug and safety wire it? How do you attach the wire to the bike? I've seen safety wire used on a "Bolt/Nut" fastener, but this is a "Bolt/Case" situation. Don't get me wrong, at this point, I'm honestly willing to hear any suggestions. I slept well last night on my decisions.

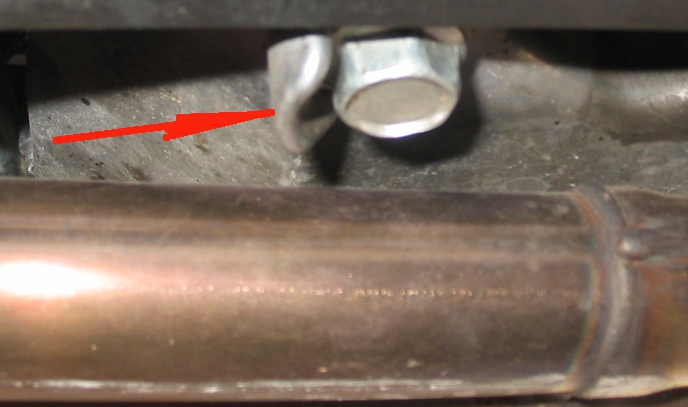

Cross-drilling the plug would be a difficult and demanding job, and it would be really easy to break those small drill bits. Instead, just drill down through the top of the plug, and out one side. It's easier done than said. You can see an unused safety-wire hole like that on the rear drive plug (red arrows). I safety-wired the drain plug to the filler plug, quick and simple.

For the crankcase drain plug, there is a lip part-way around the drain plug. It's easy to drill this aluminum lip for safety wire at the red arrow:

For the oil filter, just install a large hose clamp. I use the bolt-headed screw clamps, so I can use a small socket wrench for tightening. The clamp screw touches the engine boss, where the Allen bolt goes. The oil filter can not unscrew itself, then. Lots of room to get a small ratchet wrench in there, even with Canyon Cages:

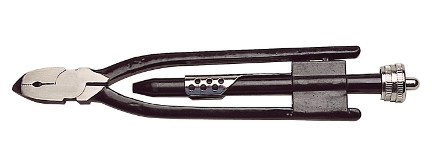

Wire twisting pliers make it easy to twist safety wire. They cost from US$8.00 up to the stratosphere. The 6" (15cm) pliers are fine for bikes, but they come in larger sizes:

Cheers,

Infrared

Totally unimpressed with the 80 miles dry run torture test.

In 1972 a mechanic replaced a seal in the manual transmission of my Datsun 1200 and forgot to refill the transmission lubricant. I left, drove 800 back to Norfolk before discovering the transmission was empty. Filled it up and drove the car another 40,000 miles with no issues.

In 1972 a mechanic replaced a seal in the manual transmission of my Datsun 1200 and forgot to refill the transmission lubricant. I left, drove 800 back to Norfolk before discovering the transmission was empty. Filled it up and drove the car another 40,000 miles with no issues.

Not to be an ******, but (sometimes I can't help myself) you've gotta be freaking kidding me!

How many properly tightened drain plugs have ever loosened and dumped their precious lubricative nectar on the tarmac in the history of FJRs? Might I suggest... NONE?

If you are a paranoid obsessive about such things, and it somehow keeps your hemorrhoids in check by twisting wires, by all means go for it At the very least you'll have something to talk about in the beer enhanced parking lot socials.

But spreading the idea that safety wire is a really good idea, or even worse, a requirement, for a street driven motorcycle is beyond the pale of absurdity. This ain't no KLR650 man.

And... since I'm in full https://www.fjrforum.com/forum//public/style_emoticons/default/******.gif mode: It aint a differential if' n you only got one wheel.

It's just a final drive. And that is all...

How many properly tightened drain plugs have ever loosened and dumped their precious lubricative nectar on the tarmac in the history of FJRs? Might I suggest... NONE?

If you are a paranoid obsessive about such things, and it somehow keeps your hemorrhoids in check by twisting wires, by all means go for it At the very least you'll have something to talk about in the beer enhanced parking lot socials.

But spreading the idea that safety wire is a really good idea, or even worse, a requirement, for a street driven motorcycle is beyond the pale of absurdity. This ain't no KLR650 man.

And... since I'm in full https://www.fjrforum.com/forum//public/style_emoticons/default/******.gif mode: It aint a differential if' n you only got one wheel.

It's just a final drive. And that is all...

Last edited by a moderator:

Spud

Well-known member

I demand all riders in front of me have both drain plugs safety wired. It's been my rule ever since I saw what happens if one comes loose and hits you in the helmet....

Last edited by a moderator:

airboss

Well-known member

Guess I'm headed for the back of the pack.

Twigg

Just an old, bald man!

I demand all riders in front of me have both drain plugs safety wired. It's been my rule ever since I saw what happens if one comes loose and hits you in the helmet....

That was a spring

G Squared

Well-known member

Did a little research today... The final drive FILL plug and the crankcase DRAIN plug are one and same. The final drive drain plug is (somehow slightly) different. But since we know firsthand the fill plug will double as a drain plug, then one extra (say fill plug) in the tool kit can serve motor oil and final drive backup duty. And if anybody was wondering,, I'm told at about 90 miles, expect catastrophic failure. Seems the head Yamaha tech. has had this conversation with Yama engineers before. Testament to the final drive unit and , I believe, the lasting effects of the lube they recommend. When apprised of the situation, (20-30 miles with no plug) he responded it probably wasn't actually dry. Still could've had some lingering oil in there.

Last edited by a moderator:

Safety wire is used for just in case. You say a properly tightened plug won't come off. OK. And you are never going to make a mistake. Safety wire prevents the consequences of the mistake. Further, most people on this forum recommend less than the Yamaha torque spec for engine drain plugs. If I am going to use half the factory torque spec, I am going to safety wire it just in case.

Last edited by a moderator:

The FD plug has a magnet and the crankcase plug does not.The final drive FILL plug and the crankcase DRAIN plug are one and same. The final drive drain plug is (somehow slightly) different.

Those two are not the same domain. Many may recommend less than the torque spec, but I doubt most are going to recommend half and even fewer are going to use wire. Call me one of those that a decently tightened plug with crush washer will NOT come off. I happen to go with 28.Further, most people on this forum recommend less than the Yamaha torque spec for engine drain plugs. If I am going to use half the factory torque spec, I am going to safety wire it just in case.

BigOgre

Well-known member

Hey 'Pants. What'd you do with the cork?

airboss

Well-known member

My crankcase drain plug does have a magnet. Since I bought an extra final drive plug to use on the crankcase.The FD plug has a magnet and the crankcase plug does not.The final drive FILL plug and the crankcase DRAIN plug are one and same. The final drive drain plug is (somehow slightly) different.

Like to see how much of that black "Dust" the magnet collects between oil changes.

Last edited by a moderator:

No I don't lose sleep at night over whether I have remembered to tighten my drain plug because I tighten the damn thing immediately as a part of installing it. It's not a multiple step process to install a drain plug. And, if somehow I were distracted (or drunk) enough to forget to install the drain plug the big puddle of clean oil on the floor would be a sure tip-off.Safety wire is used for just in case. You say a properly tightened plug won't come off. OK. And you are never going to make a mistake. Safety wire prevents the consequences of the mistake.

What about the caliper bolts. Do you safety wire those too? Or the axle nuts? What about those fork pinch bolts? There are numerous fasteners that you don't want to come loose, shouldn't they all be safety wired?

Further, most people on this forum recommend less than the Yamaha torque spec for engine drain plugs. If I am going to use half the factory torque spec, I am going to safety wire it just in case.

Seriously... hasn't this topic been beaten to death yet?

The incorrect torque spec is on the ENGINE oil drain plug. The manual says 31 ft-lbs, which is ludicrous. That is the one that gets stripped.

The (correct) torque spec in the manual for both the FINAL DRIVE fill and drain plugs is 17 ft-lbs. I have never heard of a final drive drain or fill plug being stripped, or coming loose if torqued to 17 ft-lbs.

As observed earlier, it's the same damn plug, threaded into soft aluminum alloy in all three instances.

17 ft lbs is the correct spec. It will crush the crush washer (if you have one) and will be tight enough to not come loose.

Last edited by a moderator:

Similar threads

- Replies

- 9

- Views

- 1K

Motorcycle For Sale

SOLD/My 2015 FJR1300A f/s- SOLD

- Replies

- 18

- Views

- 2K

Motorcycle For Sale

2007 Yamaha FJR 1300 with extras

- Replies

- 1

- Views

- 595

- Replies

- 16

- Views

- 2K