Inlaw1

Well-known member

Recently installed the AV CC on my 06 with the help of a very qualified mechanic buddy. I'd like to thank Smitty for his phone number to call and ask a couple of questions. As everyone has stated, very stand up guy. After doing the install, and taking practically apart to fix a water leak at the cross over pipe, then to fix a snag with the chain / cable, then to re-run hosed... I'm confident to say this really isn't that hard of an install.

So we got the unit installed under the tank like the AE's (mine is just an A) as I wanted the room under the seat. I ran the vacuum off the MAP sensor like FJRcarshopguy had done but I don't think it gave a very strong vacuum signal. In windy conditions the bike would not hold speed unless you helped the throttle along occasionally. Lost speed up hills, unless helped, etc.

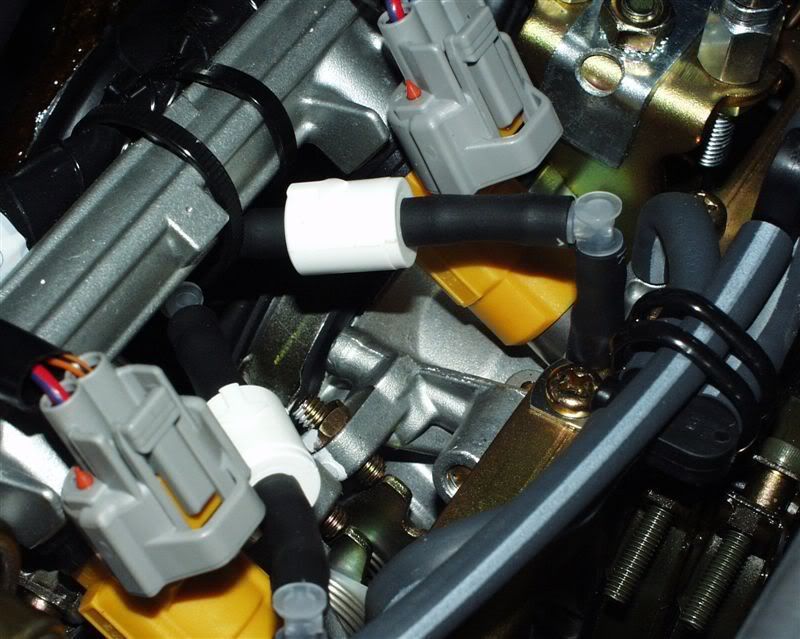

I connected all the spare ports used for the throttle body synch by teeing the two on the left and the two on the right then teeing those two sets into the line for the servo and vacuum cannister. It pulls mucho better now. Works like it's supposed to.

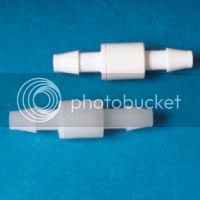

I have a question though: Does anyone have a part number and application for a check valve? I've gone to all my local auto parts stores and they are populated with dolts. I had to help them find the generic check valves they had, and it's not what I'd like to use. I would like something with 3/16th inlet / outlet to fit the vacuum hose I'm using. The best one I found at the local auto parts is way too small to fit this hose.

Ideas? Comments? Questions? Answers?

Thanks.

So we got the unit installed under the tank like the AE's (mine is just an A) as I wanted the room under the seat. I ran the vacuum off the MAP sensor like FJRcarshopguy had done but I don't think it gave a very strong vacuum signal. In windy conditions the bike would not hold speed unless you helped the throttle along occasionally. Lost speed up hills, unless helped, etc.

I connected all the spare ports used for the throttle body synch by teeing the two on the left and the two on the right then teeing those two sets into the line for the servo and vacuum cannister. It pulls mucho better now. Works like it's supposed to.

I have a question though: Does anyone have a part number and application for a check valve? I've gone to all my local auto parts stores and they are populated with dolts. I had to help them find the generic check valves they had, and it's not what I'd like to use. I would like something with 3/16th inlet / outlet to fit the vacuum hose I'm using. The best one I found at the local auto parts is way too small to fit this hose.

Ideas? Comments? Questions? Answers?

Thanks.