Joe2Lmaker

Well-known member

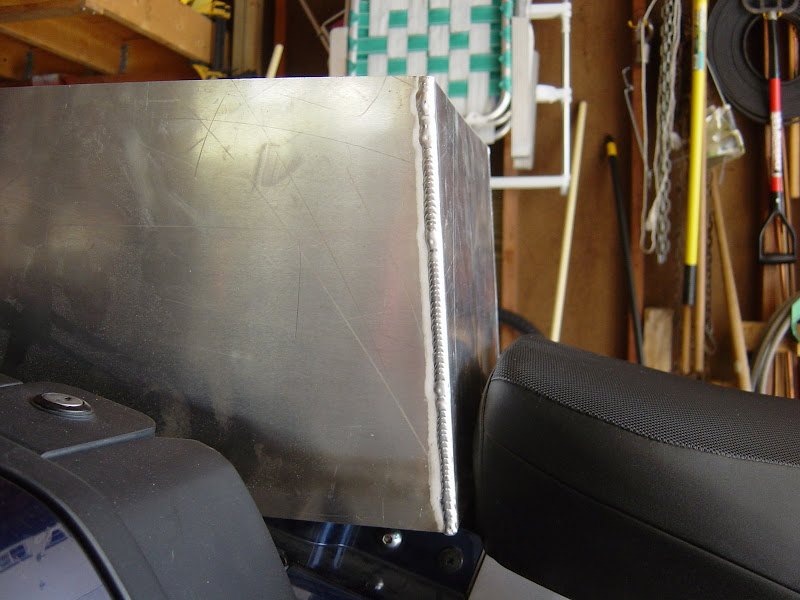

Wednesday I drove to the shop that was going to do the welding for me. I had the various plates that make up the tank with me, some I made and the bottom plate that was made for me. I was really looking forward to seeing all of those pieces come together.

Things looked pretty quiet and I wondered if they were still in business. I drove around to the front entrance and saw something taped to the door. I got out of my truck and walked up to the door expecting a "We have moved" note. But it was actually an eviction notice from the sheriff. Bummer. For two days, I wondered what happened. I questioned myself and my ability judge character. Now what was I going to do?

Things have a way of working out.

One of the guys I work with who rides, but questions my sanity for wanting to carry an auxiliary tank, hooked me up with a very competent welder. I stopped by his shop today and early next week he's going to weld my tank for me. Hell of a nice guy. I'm back to being excited to see the pieces come together.

A week from today I might actually post photos of the completed version of the flat top/over the tail tank.

Things looked pretty quiet and I wondered if they were still in business. I drove around to the front entrance and saw something taped to the door. I got out of my truck and walked up to the door expecting a "We have moved" note. But it was actually an eviction notice from the sheriff. Bummer. For two days, I wondered what happened. I questioned myself and my ability judge character. Now what was I going to do?

Things have a way of working out.

One of the guys I work with who rides, but questions my sanity for wanting to carry an auxiliary tank, hooked me up with a very competent welder. I stopped by his shop today and early next week he's going to weld my tank for me. Hell of a nice guy. I'm back to being excited to see the pieces come together.

A week from today I might actually post photos of the completed version of the flat top/over the tail tank.