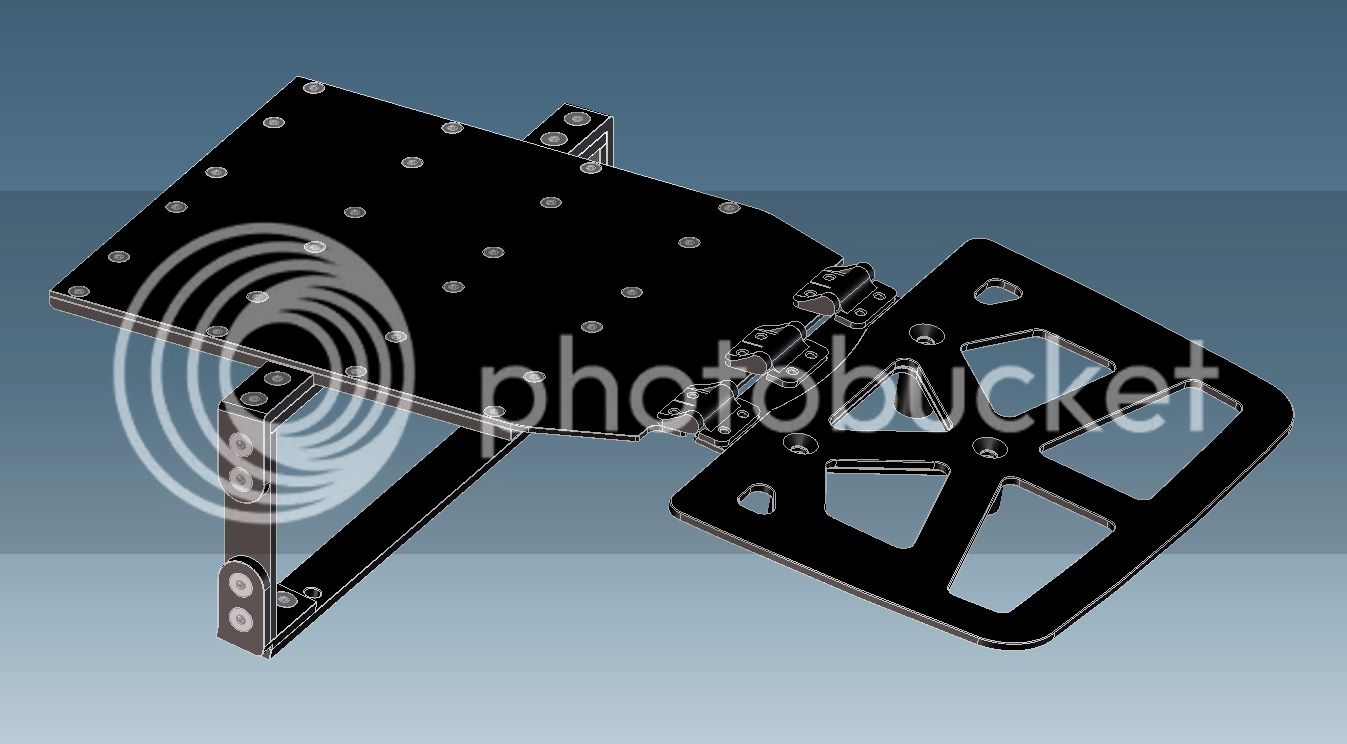

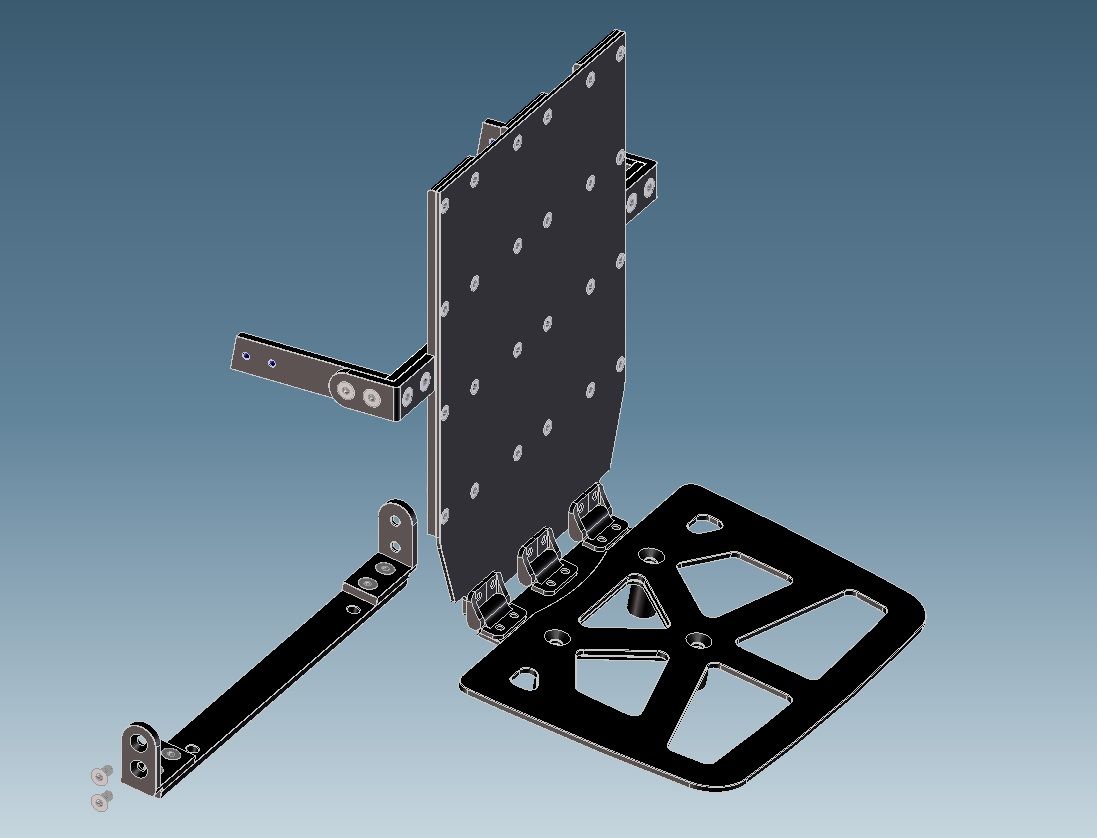

Oh, that is freaking awesome. I'm constantly astounded at the design capability of some people here. Being able to move the trunk forward to centralize mass, and at the same time eliminate any aerodynamic issues that cause high speed wobble with a trunk and no passenger, is a huge win-win. I know I've said it before about your design, but it bears repeating.

Did you use the really great valve spread sheet from the Forum ?

Really good spread sheet when working on the valve clearances.

I've always made up my own maintenance recording sheets on my 2d CAD system. I keep meticulous records on everything I do to each vehicle I own (and have owned for the past few decades). I have all these in a binder on the book shelf with a dozen or so FSMs. The FSMs stack up even after the vehicle is long gone, for some reason I just can't throw them out.

Dan

Do take a look at the spreadsheet. It was put together by Billy Fitz (Yammafitter) here on the forum, and it is a stroke of pure genius. I helped him clean it up a little and make it as useful as possible, but all credit goes to Bill.

The advantage of the spreadsheet is that, not only does it give you a great data sheet to record the as found and as set clearances, it also calculates what you will ideally want to install for the new shims with no need for a lookup table.

I do suggest that anyone that after making initial clearance measurements thinks that they will need to re-shim, to switch from using imperial, inch-based measurements, to metric feelers. The accuracy of the readings is more than doubled, which can only be a good thing.

I have what I believe to be the latest version of the spreadsheet hosted on Dropbox here:

FJR Valve Clearances rev 1.xls

You can download the file without joining or giving away your first born children, just say "No Thanks" when they spam you to become a member. They'll still let you get the file.

As for having the right shims, you do not need all of the shim sizes that come in a standard re-shim kit. Those kits are designed to cover a wide range of bikes and manufacturers, that use widely different stock shim sizes out of the factory. I did a survey at one time to try and nail down the most commonly found stock shims in FJR engines, and that is no doubt languishing somewhere on this cloud of forum data and could be found with some diligent searching. I seem to recall that it comes down to only about 2-3 sizes of intake and exhaust sizes being

needed, but be aware that the factory uses shims of much smaller differences (.01mm) to hit their production tolerances as compares to what is available during re-shim (.05mm).

My take on this was to say screw it and sand the original shims down to what I needed to hit the 70th percentile using a micrometer, to the .01mm (actually tighter) level of accuracy. Again, there are several accounts of people sanding shims documented on here, including my own.

Lots of ways to approach this thing, but none of them are all that complicated once you understand the principles and what you are attempting to achieve.

PS - I know what you mean about throwing away old FSMs. They are like our children. We can't just leave them at the dump, even if nobody else wants them.