NTXFJR

Well-known member

Update: After a few delays I finally got this thing working today. It doesn't seem like the journey should've had to have been so trying, but at least it's working now. It really is pretty smooth with the current hardware setup and dipswitch settings. I had it out on the interstate earlier and tried it out at speeds up to 80mph, which is plenty fast enough for me on cruise control. When initially set, it surges slightly, maybe a couple mph, then it settles in and holds the speed to within 1 mph or so. I'm very pleased with it's performance at this point. Bumping the accel or decel 4 clicks gives about a 5 mph adjustment. I was ready to throw a party after this one, sheesh.

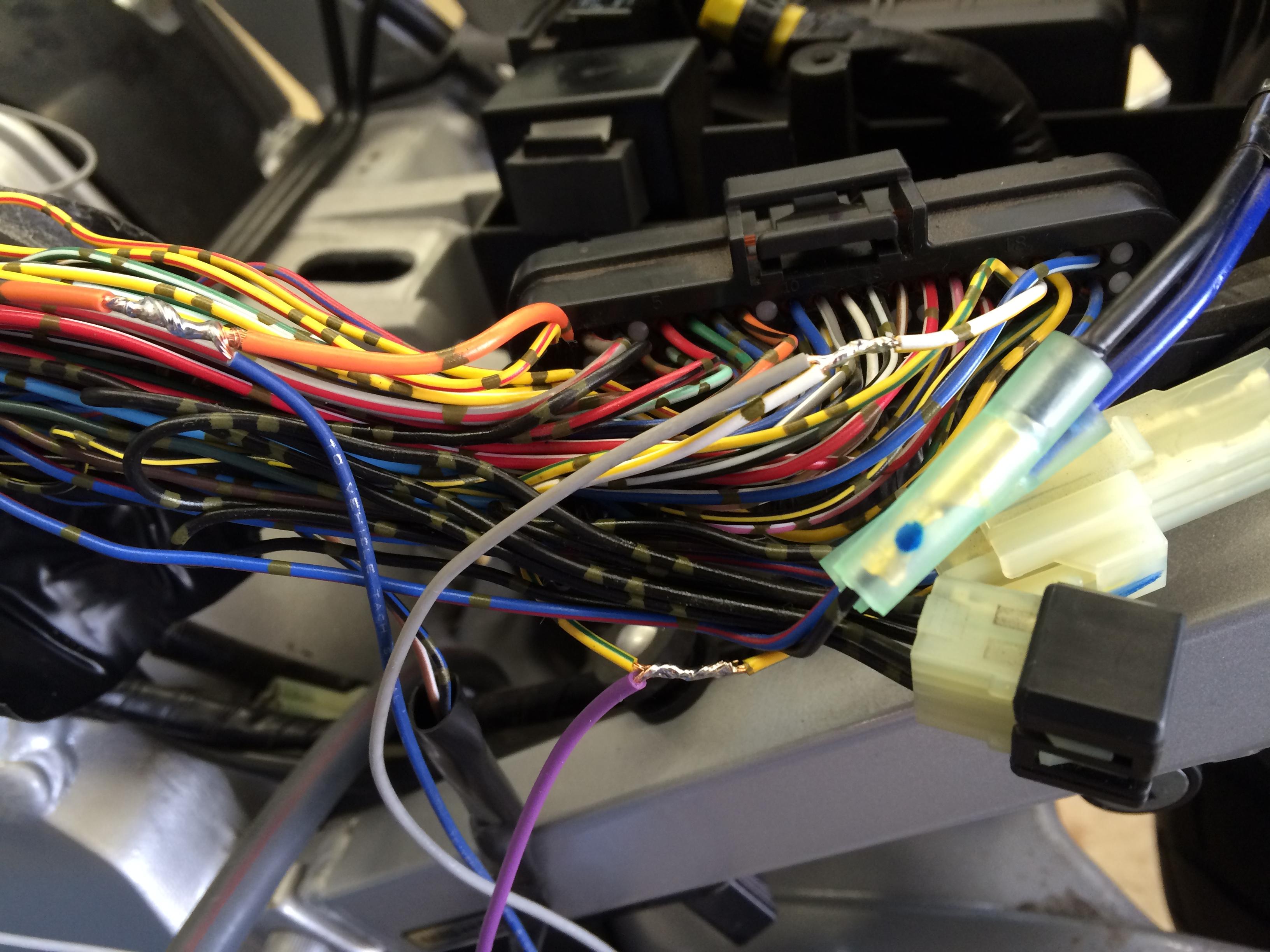

The hardware I added to get this thing working was:

Rostra Switch 250-3592 + relay for engaged indicator light

Rostra vss kit 250-4165

Koso M6x20mm Speed Sensor Magnet Bolts BF010611

Black Vinyl Sleeving to dress up the vss wires as they route up the swing arm

Dipswitch settings I ended up using (very smooth factory style performance imo)

1 off

2 off 1-2) Gain Sensitivity Extra Low

3 on

4 off

5 off

6 off 3-6) 4k pulses per mile

7 off

8 off

9 off 7-9) Engine Setup V8 low

10 off Sine Wave

11 on Automatic Transmission

12 off Open Circuit Switches

I ended up tying the blue tach wire to ground. I'm not too worried about over revs, I figure all it takes is a tap on the brakes to shut it down. Down the road, I want to look into tying the orange clutch wire into the clutch switch circuit. But that's for another day.

Some of the biggest issues I fought on this one: The servo unit quit responding to accel / set inputs after the initial trial last month while using the bike's vss, even after trying the 4:1 pulse divider. After it quit responding to the inputs, I wasn't sure if it was the switch, the servo, or the wiring. After a check of the wiring, nope nothing loose or shorted, so I went ahead and ordered a new switch and a new servo unit not knowing which one it could be, and started by replacing the switch. Nope, switch wasn't it, onto the servo unit. In the end, all it took was completely removing power from the servo (by removing the wiring harness connector from the servo box) to get it to reset and restart again. So, lol, I now have an extra Rostra brand new in box if anyone is interested. I'll post it in the for sale thread, if nobody want's it it'll go back. On the vss kit, I wound up having to put the pick up coil just about on top of the magnets with a slight offset off of center get a good signal. Rostra's install manual called for .5 to 1 inch spacing, I'm calling bravo sierra on that one.

Thanks to all for your input. I'm glad you Gen II and Gen III'ers don't have to go through this crap.

The hardware I added to get this thing working was:

Rostra Switch 250-3592 + relay for engaged indicator light

Rostra vss kit 250-4165

Koso M6x20mm Speed Sensor Magnet Bolts BF010611

Black Vinyl Sleeving to dress up the vss wires as they route up the swing arm

Dipswitch settings I ended up using (very smooth factory style performance imo)

1 off

2 off 1-2) Gain Sensitivity Extra Low

3 on

4 off

5 off

6 off 3-6) 4k pulses per mile

7 off

8 off

9 off 7-9) Engine Setup V8 low

10 off Sine Wave

11 on Automatic Transmission

12 off Open Circuit Switches

I ended up tying the blue tach wire to ground. I'm not too worried about over revs, I figure all it takes is a tap on the brakes to shut it down. Down the road, I want to look into tying the orange clutch wire into the clutch switch circuit. But that's for another day.

Some of the biggest issues I fought on this one: The servo unit quit responding to accel / set inputs after the initial trial last month while using the bike's vss, even after trying the 4:1 pulse divider. After it quit responding to the inputs, I wasn't sure if it was the switch, the servo, or the wiring. After a check of the wiring, nope nothing loose or shorted, so I went ahead and ordered a new switch and a new servo unit not knowing which one it could be, and started by replacing the switch. Nope, switch wasn't it, onto the servo unit. In the end, all it took was completely removing power from the servo (by removing the wiring harness connector from the servo box) to get it to reset and restart again. So, lol, I now have an extra Rostra brand new in box if anyone is interested. I'll post it in the for sale thread, if nobody want's it it'll go back. On the vss kit, I wound up having to put the pick up coil just about on top of the magnets with a slight offset off of center get a good signal. Rostra's install manual called for .5 to 1 inch spacing, I'm calling bravo sierra on that one.

Thanks to all for your input. I'm glad you Gen II and Gen III'ers don't have to go through this crap.