meosborn

Well-known member

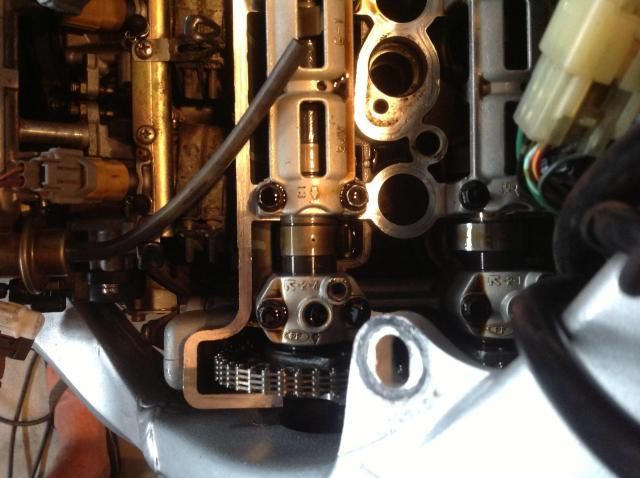

This is all on my 2003 FJR1300RC. 60k.

So after performing a number of maintenance actions (valve clearance check, TBS, cleaned intake butterflies) I have been having a problem with a nasty hesitation when accelerating from slow speeds.

I have been all over the forum and it seems that there have been a number of people that have had similar problems for what appears to be a variety of reasons. I have checked the battery, cleaned the large electrical connectors under the tank, checked the TPS, swapped the pressure sensor with the atmospheric pressure sensor under the seat, checked the readings using new vacuum hose and I've checked the IPS with a Mityvac.

Someone on the forum mentioned that the ECU has a default map for the IPS so I tried running it with the IPS unplugged. It ran much better although not perfect. To me this points to the intake pressure as the problem.

When I run the diagnostics and use diAG 03 which is supposed to read 10-200 mm Hg I get 7 or 11 and sometimes 15. I suppose technically this is over the minimum value but it seems odd to me. Coupled with how it ran with the IPS unplugged I think this must be low. When I hooked the IPS to one throttle body at a time the reading goes up in the 130s, with two connected it drops to the 50s or 60s, with three it goes to the 20s and 30s.

One thing I notice was that there is a pulse of air that comes out of the throttle body as well when the engine is turned over. This all seems to make sense when I consider that with all four hooked together the pulses of air must cancel out the vacuum.

I cannot rule out something else causing the hesitation in the acceleration but right now I'm focusing on the intake pressure reading since it's the only abnormal indication that I have found and it has me baffled.

So all that boils down to at least two questions at this point. First, if you have a GenI, what reading do you get from the diAG 03 check? Second, is there someone out there that can explain the intake vacuum system to me so that I might be able to figure out what the problem might be?

So after performing a number of maintenance actions (valve clearance check, TBS, cleaned intake butterflies) I have been having a problem with a nasty hesitation when accelerating from slow speeds.

I have been all over the forum and it seems that there have been a number of people that have had similar problems for what appears to be a variety of reasons. I have checked the battery, cleaned the large electrical connectors under the tank, checked the TPS, swapped the pressure sensor with the atmospheric pressure sensor under the seat, checked the readings using new vacuum hose and I've checked the IPS with a Mityvac.

Someone on the forum mentioned that the ECU has a default map for the IPS so I tried running it with the IPS unplugged. It ran much better although not perfect. To me this points to the intake pressure as the problem.

When I run the diagnostics and use diAG 03 which is supposed to read 10-200 mm Hg I get 7 or 11 and sometimes 15. I suppose technically this is over the minimum value but it seems odd to me. Coupled with how it ran with the IPS unplugged I think this must be low. When I hooked the IPS to one throttle body at a time the reading goes up in the 130s, with two connected it drops to the 50s or 60s, with three it goes to the 20s and 30s.

One thing I notice was that there is a pulse of air that comes out of the throttle body as well when the engine is turned over. This all seems to make sense when I consider that with all four hooked together the pulses of air must cancel out the vacuum.

I cannot rule out something else causing the hesitation in the acceleration but right now I'm focusing on the intake pressure reading since it's the only abnormal indication that I have found and it has me baffled.

So all that boils down to at least two questions at this point. First, if you have a GenI, what reading do you get from the diAG 03 check? Second, is there someone out there that can explain the intake vacuum system to me so that I might be able to figure out what the problem might be?