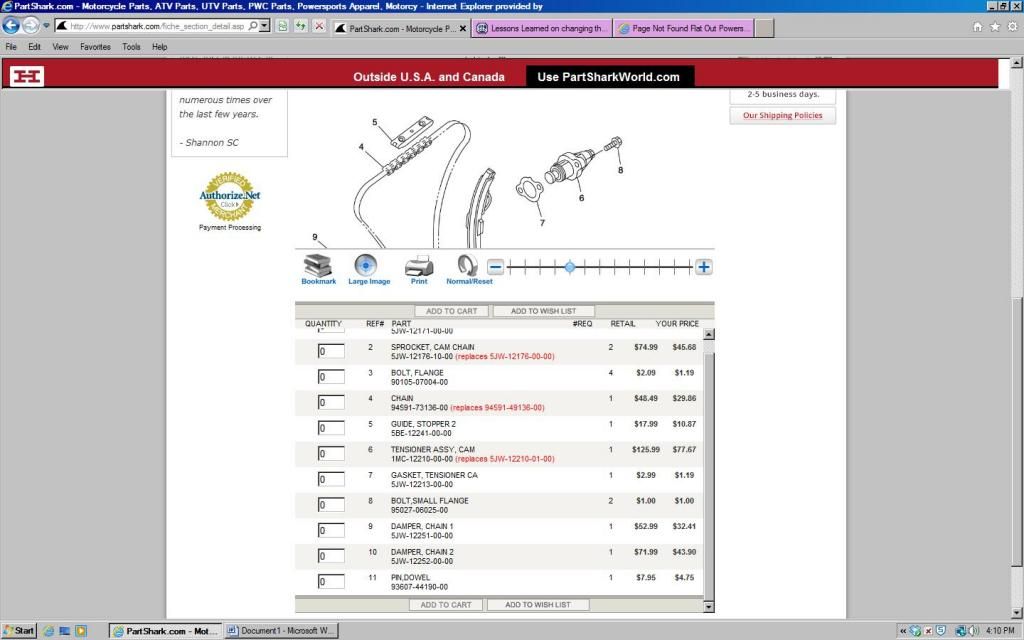

I just finished changing the CCT on my bike and the engine does sound quieter even if I never thought it noisy except for one brief incidence.

I didn't do the slotted bolt trick, but I think that's a good idea for those who prefer it. No two cats are skinned alike.

I considered enlarging the frame hole a bit, but didn't do that either. I bought a kit of Craftsman metric ignition wrenches for ~$22. I also cut a 1/4" drive 8mm socket shorter and it fit better. That way I could use a flexible drive and extension to run the pair of bolts in; final tightening with the ignition wrench and regular 8mm.

Another good tip previously mentioned is using plastic electrical tape to hold bolts to tools or in some cases slightly alter tools temporarily for certain jobs.

That's about it from me except to say thanks to everyone posting here.

I didn't do the slotted bolt trick, but I think that's a good idea for those who prefer it. No two cats are skinned alike.

I considered enlarging the frame hole a bit, but didn't do that either. I bought a kit of Craftsman metric ignition wrenches for ~$22. I also cut a 1/4" drive 8mm socket shorter and it fit better. That way I could use a flexible drive and extension to run the pair of bolts in; final tightening with the ignition wrench and regular 8mm.

Another good tip previously mentioned is using plastic electrical tape to hold bolts to tools or in some cases slightly alter tools temporarily for certain jobs.

That's about it from me except to say thanks to everyone posting here.