hppants

Well-known member

Interesting in that word got to the dealer before you did.

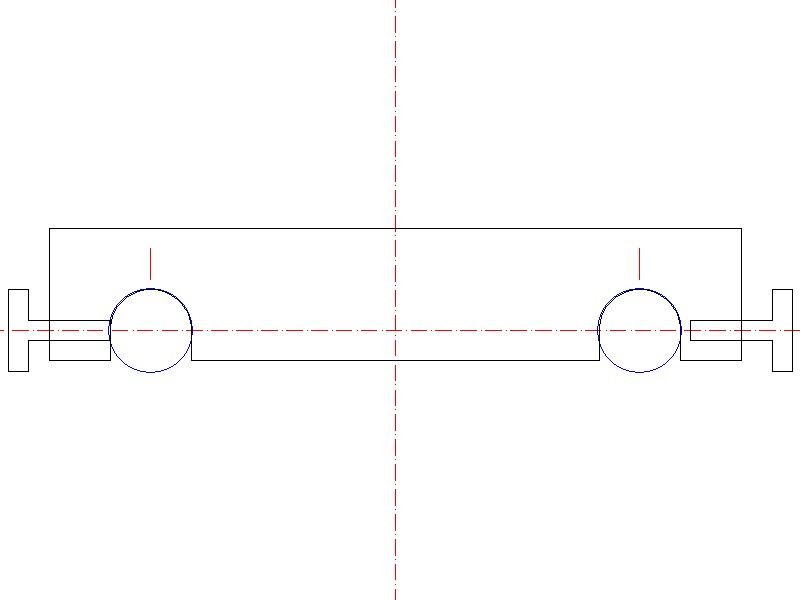

<snip>...a tool could be made for FJRs, would need to engage with a reference point on the cylinder head and the holes in the cam sprockets.

Cheers

Gary

Knowing this before going in is really helpful. I agree with Ray that it isn't hard to see if you KNOW what to look for. There are enough markings (cam shaft, cam sprockets, and crank) to know if it is correct. Like HPPants, I learned the hard way.IMHO, no need for a special tool, hardly enough room for one anyway..... Line up the timing marks (arrows) on the cam sprockets to the cylinder head as shown in the FSM, which should coincide with the crankshaft end being lined up at #1 TDC.. That is step 1 in case you move stuff later, you have proper reference points. Small zip tie to each camshaft sprocket, and zip tie the crankshaft end. Now you can remove/back off the CCT, remove and replace cams at will, and when you're done, verify those timing marks are still lined up. They should be... rotate the engine 360, check the cams rotated 180 (same timing marks), rotate again 360, cams now rotated back to your starting point...... to me this is not difficult but I've done it many times. It helps to be familiar with the timing marks. Sit on a stool and gunsight with a good flashlight, not a lot of room, but (to me) they aren't all that hard to see. Before you start, you can rotate the engine to various positions to verify what the marks look like.......

Thank you! How frikkin hard is it to sight and line up cam timing marks? There's a new-fangled invention that, along with a flashlight, makes it so easy even a zilla can do it!!IMHO, no need for a special tool, hardly enough room for one anyway..... Line up the timing marks (arrows) on the cam sprockets to the cylinder head as shown in the FSM, which should coincide with the crankshaft end being lined up at #1 TDC.. That is step 1 in case you move stuff later, you have proper reference points. Small zip tie to each camshaft sprocket, and zip tie the crankshaft end. Now you can remove/back off the CCT, remove and replace cams at will, and when you're done, verify those timing marks are still lined up. They should be... rotate the engine 360, check the cams rotated 180 (same timing marks), rotate again 360, cams now rotated back to your starting point...... to me this is not difficult but I've done it many times. It helps to be familiar with the timing marks. Sit on a stool and gunsight with a good flashlight, not a lot of room, but (to me) they aren't all that hard to see. Before you start, you can rotate the engine to various positions to verify what the marks look like.......

Good point, and good thinkin'While it's easy to see the machined marks on the intake cam, as we know the exhaust cam is not so easy. But, it is easy to juxtapose the sprocket teeth where the two sprockets are nearest each other.

I think it was you that came up with the idea of jamming a 10 mm socket into the front chain slipper to avoid a slip during a change of the CCT. Works like a charm.The "special tool" I'm envisioning is to restrain the chain on the lower sprocket, as that is the end that generally jumps a tooth. A Ty-wrap on each of the cam sprockets is easy, since those sprockets have handy holes in them. The trickier part is restraining the lower sprocket and still having enough chain slack to move the ty-wrapped cams around on top.

I actually didn't even restrain mine there when I re-shimmed my '05, and just left the ty-wraps on up top until I got the timing right at the bottom end. The trick for me was to slightly rotate the crankshaft CCW a few degrees from #1 TDC with the valves still on their marks, to allow the chain to slip on the lower sprocket in correct time when the chain is tight.

Enter your email address to join: