The cam caps are labeled I1 I2 E1 E2 etc. and I placed each one carefully in order when I took them off, so I'm quite certain I didn't get them on in the wrong order. I have ordered more shims so I will see what happens once I receive the new shims and put everything back together.

I only moved the cams far enough out of the way to remove the lifters so I really don't think I could have bent a cam. I only removed the lifters where shims were being replaced. So I'm certain I didn't mix up the lifters/buckets. When I took the lifter off in order to take the shim out, I put the lifter right back in so that any mix ups were impossible.

So I'm not sure WTF happened. Once I get the new shims, I won't be ordering any more. All of my clearance readings have been .001 on the tight side, so I should be able to sand down any additional shims. Once I get the new shims, I'll see what transpires next.

I also replaced the CCT, but I don't see how that could have effected the clearances.

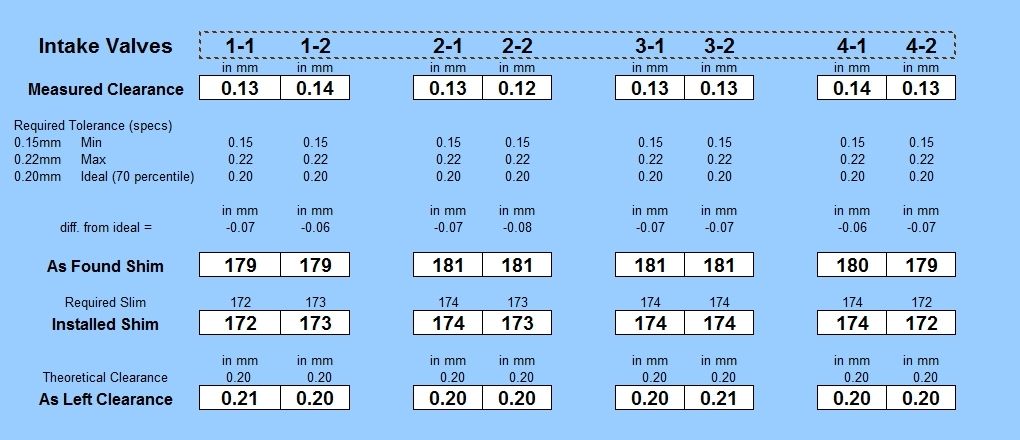

Initially I only had one intake (cyl. #3) that was .001 too tight and one exhaust that was .001 too tight (cyl. #4). Now I have both intakes on cyl#1 and cyl#2 .001 too tight and one exhaust on cal #3 .001 too tight. So including the original shims (two) this makes a total of seven shim replacements which seems to be unheard of for a first valve check/adjust with 26K miles.

In addition, I spun the crank around at least 3 times and made the original measurements multiple times to validate the measurements and ensure I got consistent results before pulling the cams and lifters.

Once I put the cam caps back on, I did the same thing by spinning the crank around multiple times and made the measurements multiple times. As stated before, once I get the new shims back in, hopefully I'll get consistent results this time. Maybe it was the Jameson's Irish Whiskey the night before?

I loosened and then re torqued the cam caps and still have four additional ones out of spec that weren't before removing the cams and and reinstalling them. Not sure how this could happen?

I loosened and then re torqued the cam caps and still have four additional ones out of spec that weren't before removing the cams and and reinstalling them. Not sure how this could happen?