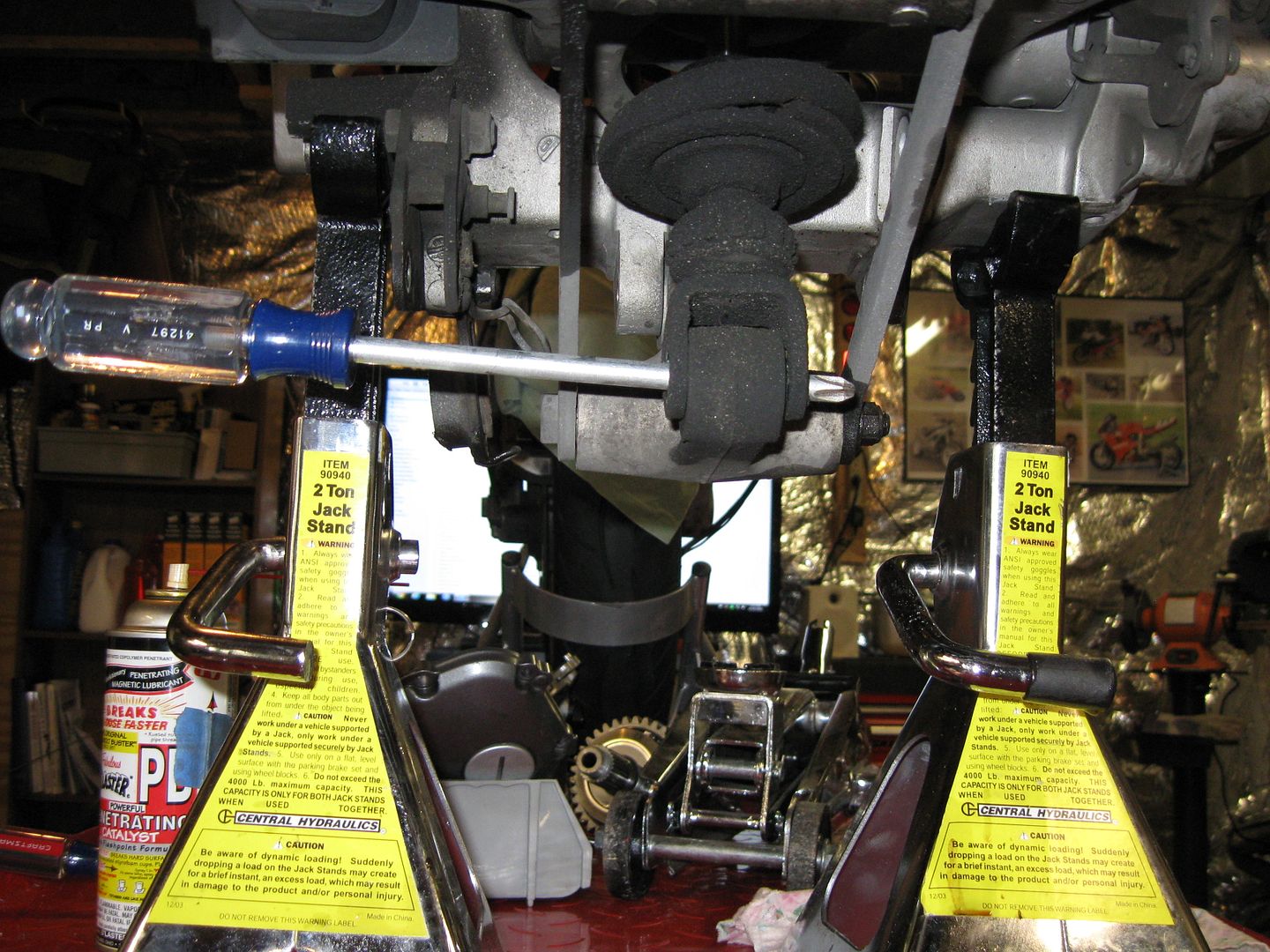

You may remember the bike-er-frame got put up on jack stands to help facilitate the removal of the centerstand and ultimately the swing arm linkage.

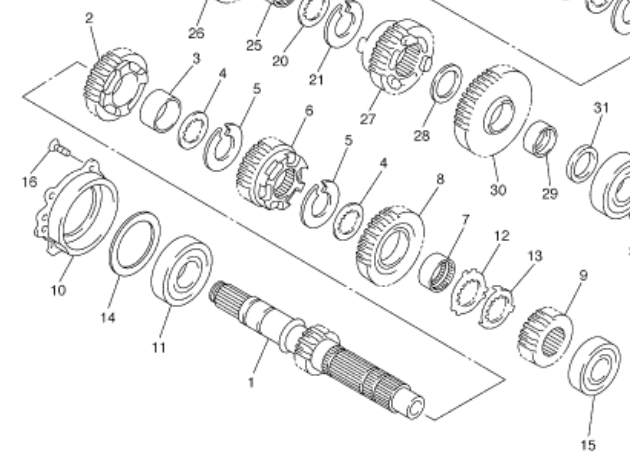

Well, I said earlier, "he can be taught" and to be taught.... I need to learn... which means, puzzle time!

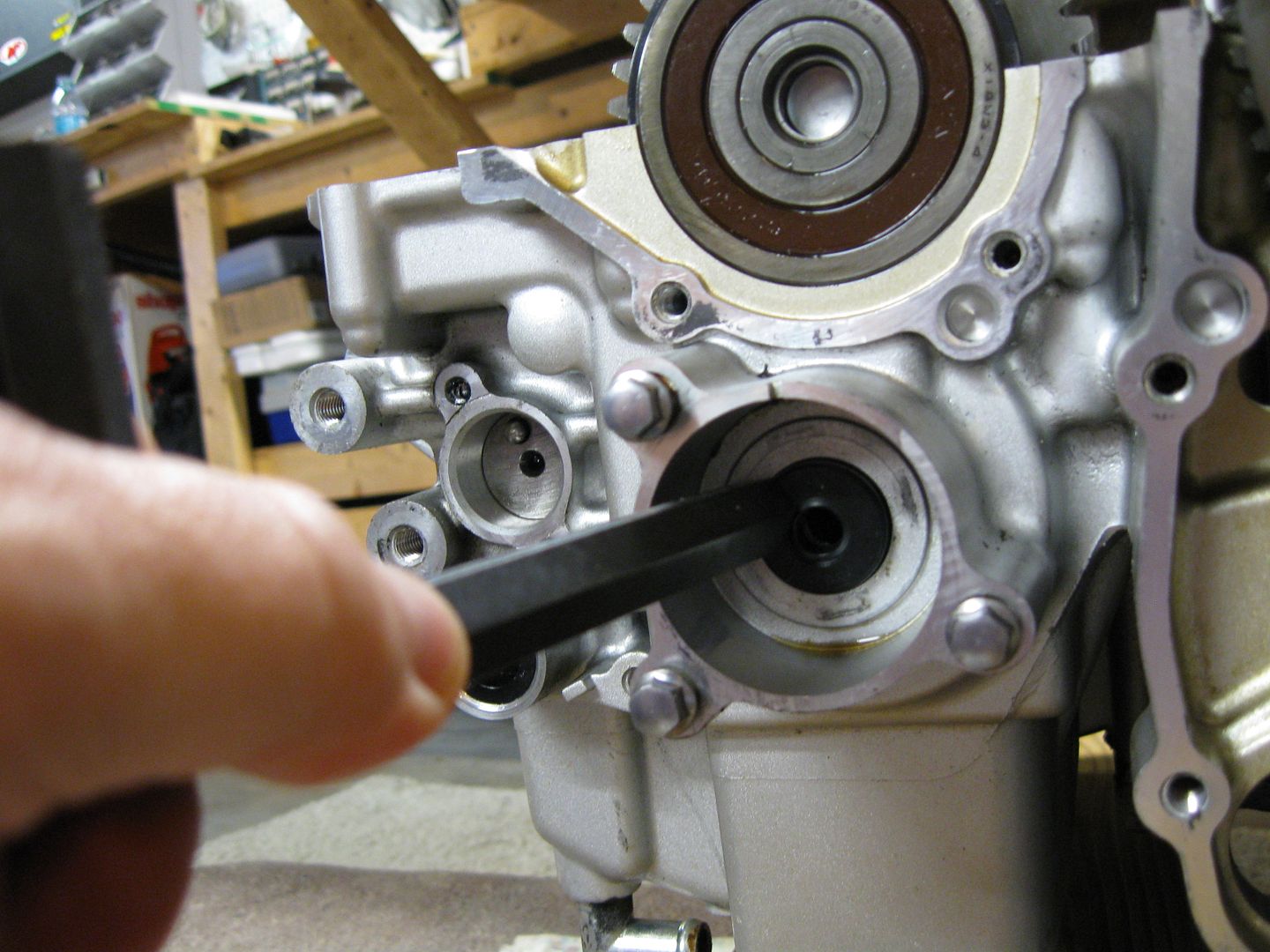

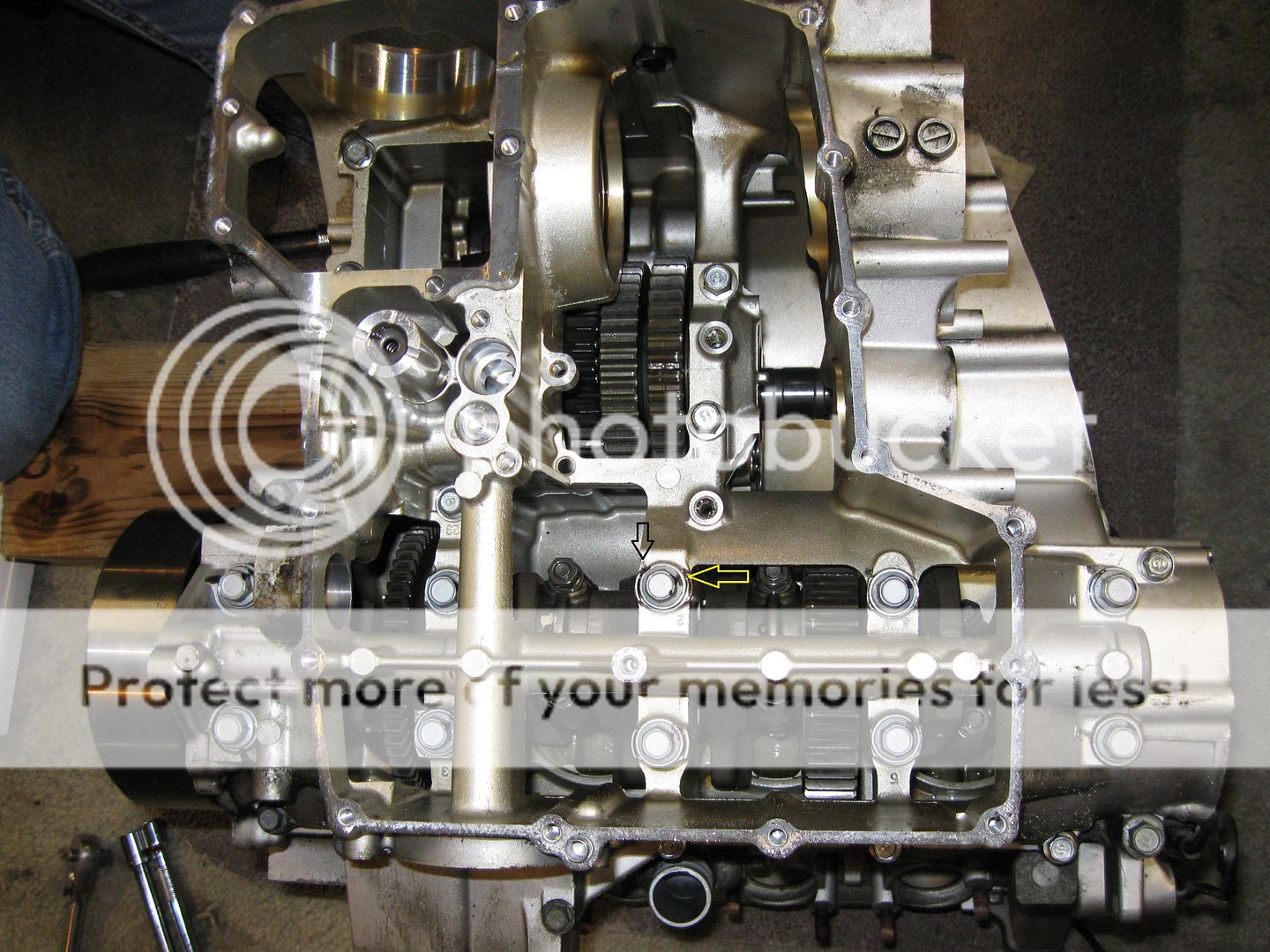

Look hard for a moment and it comes to you. It didn't me so, I had to move some things around and ...... well, take a look see!

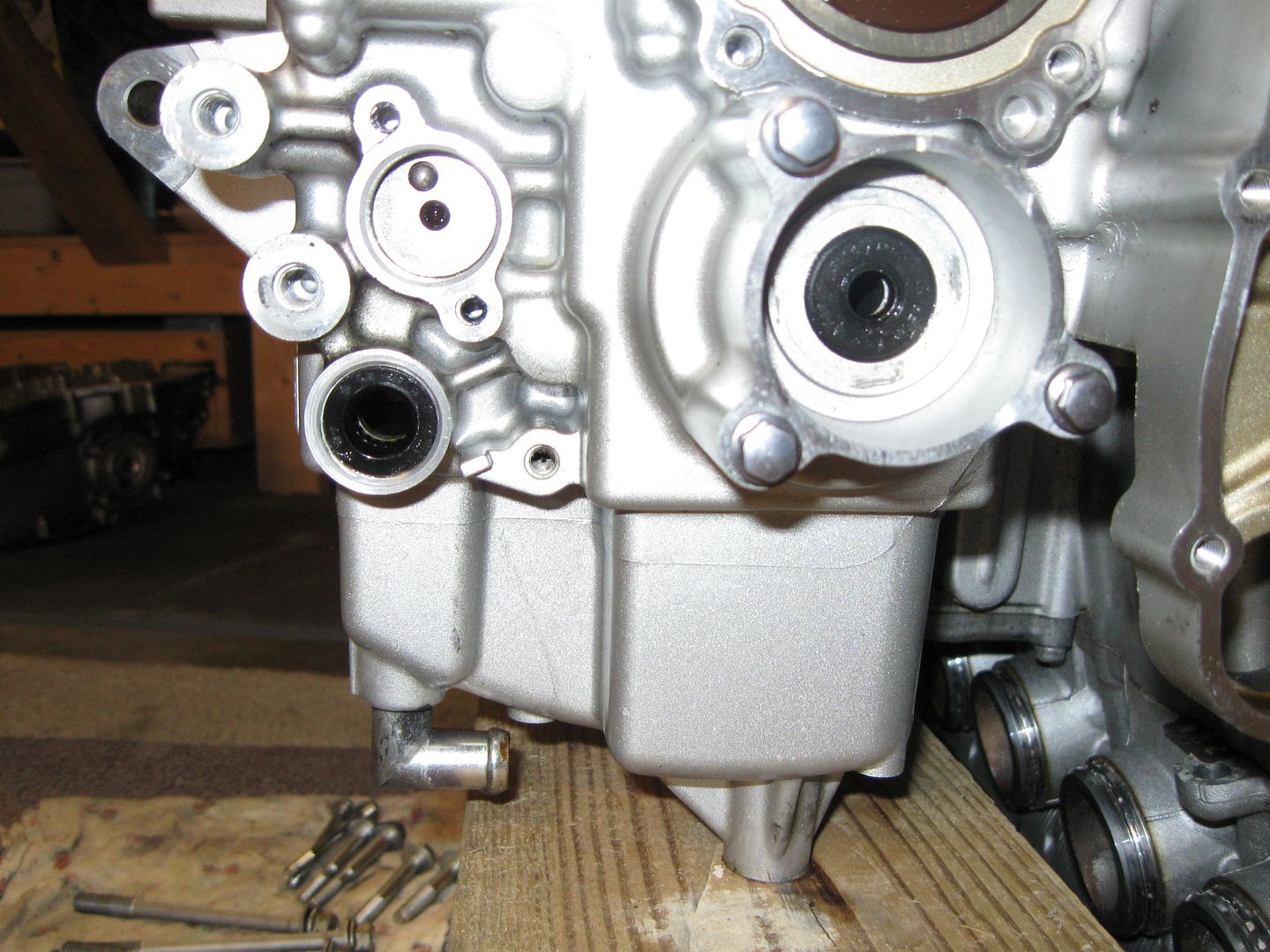

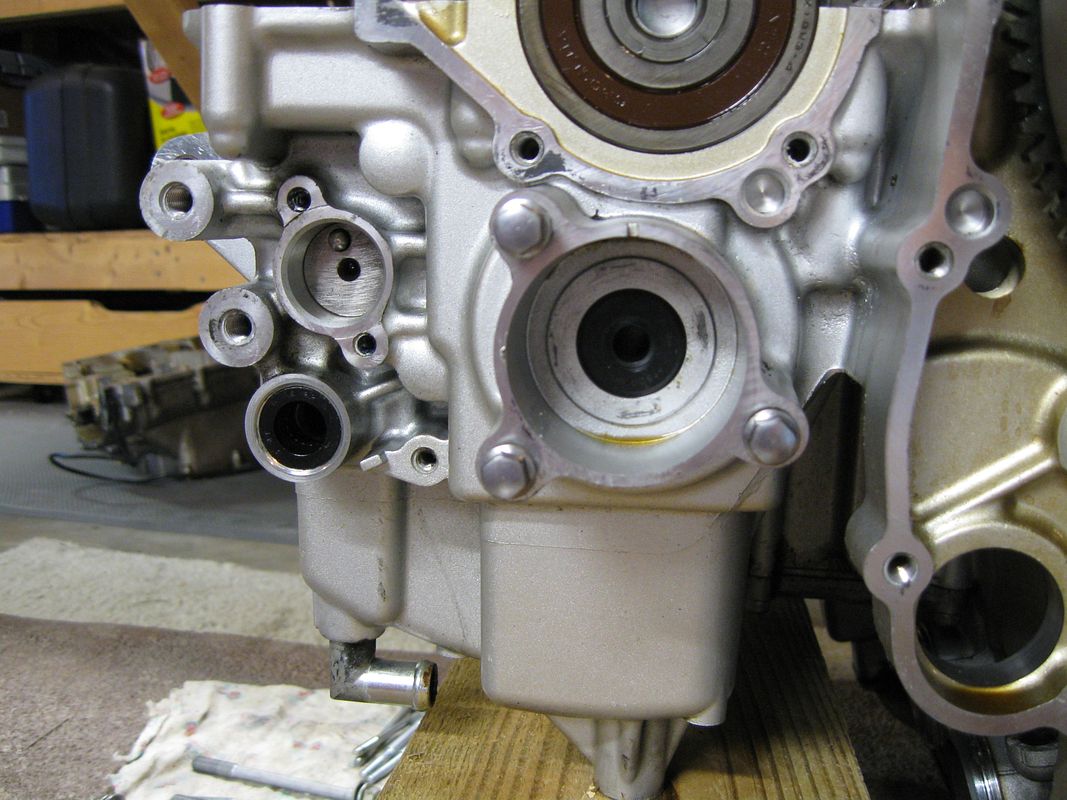

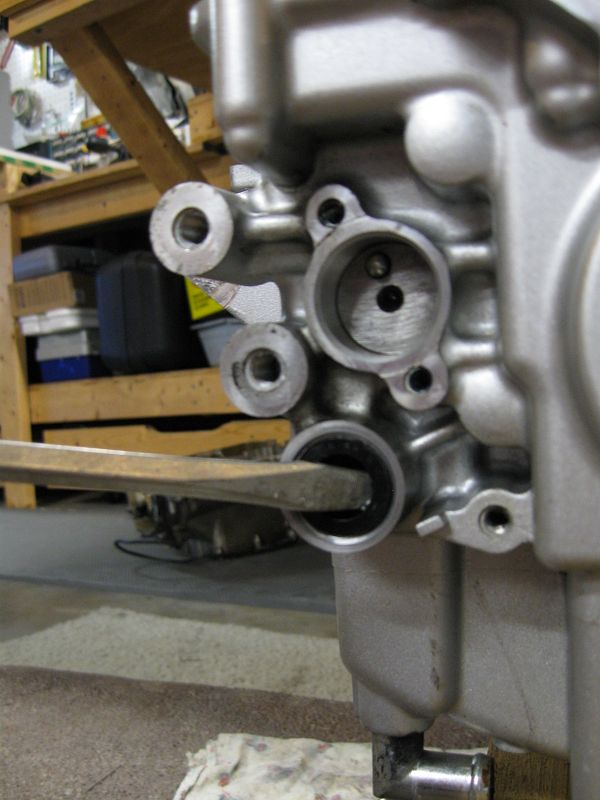

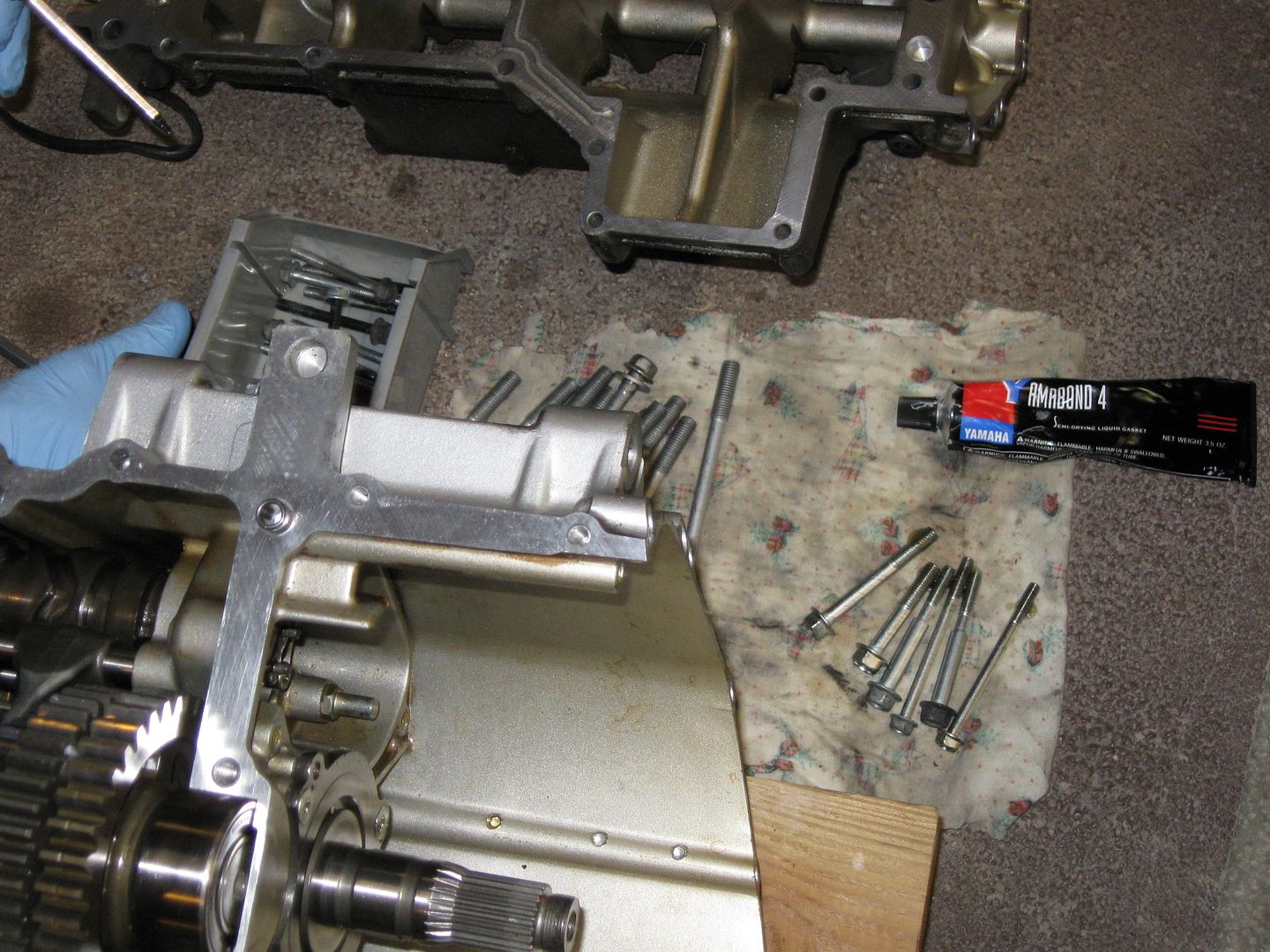

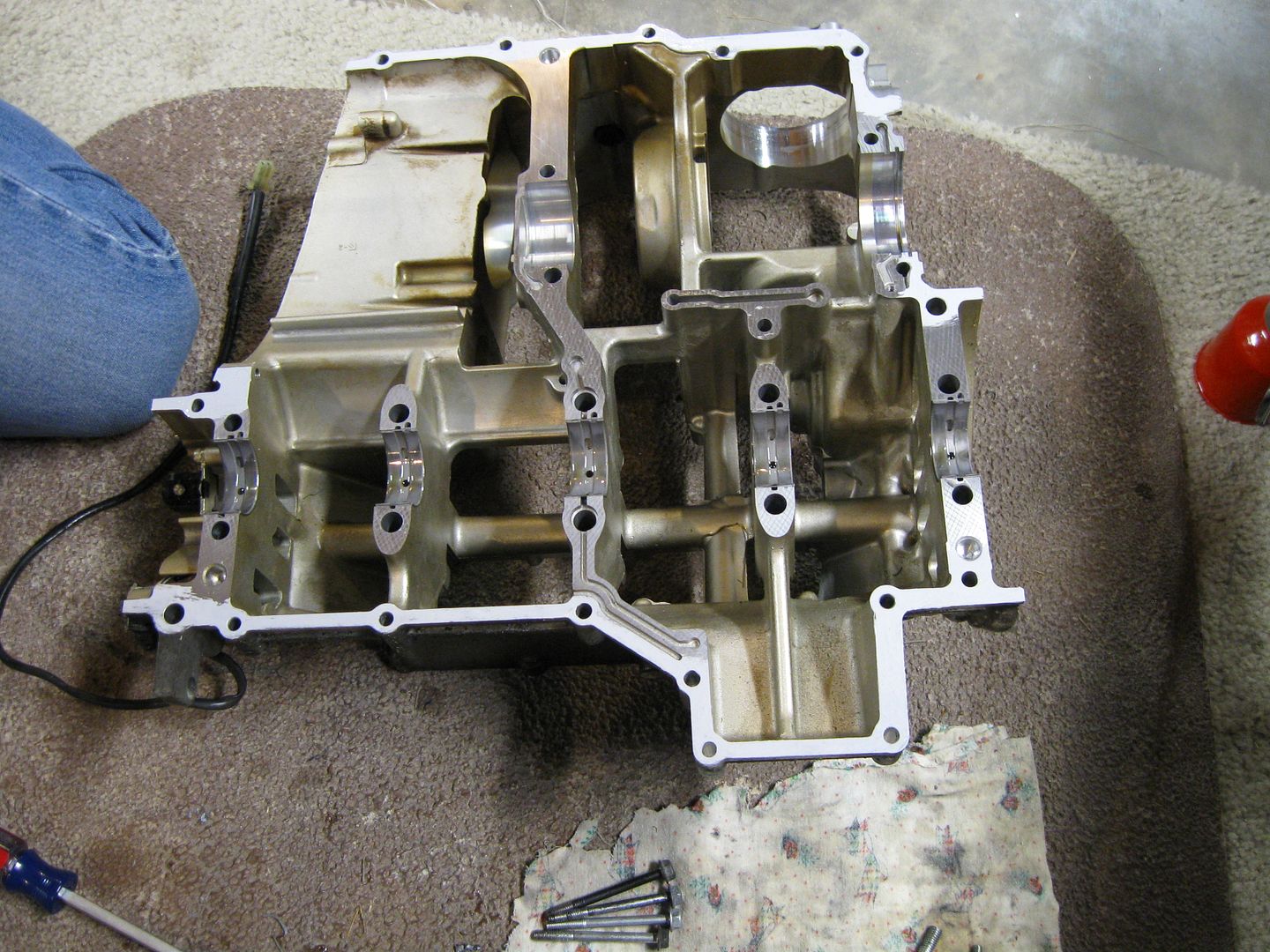

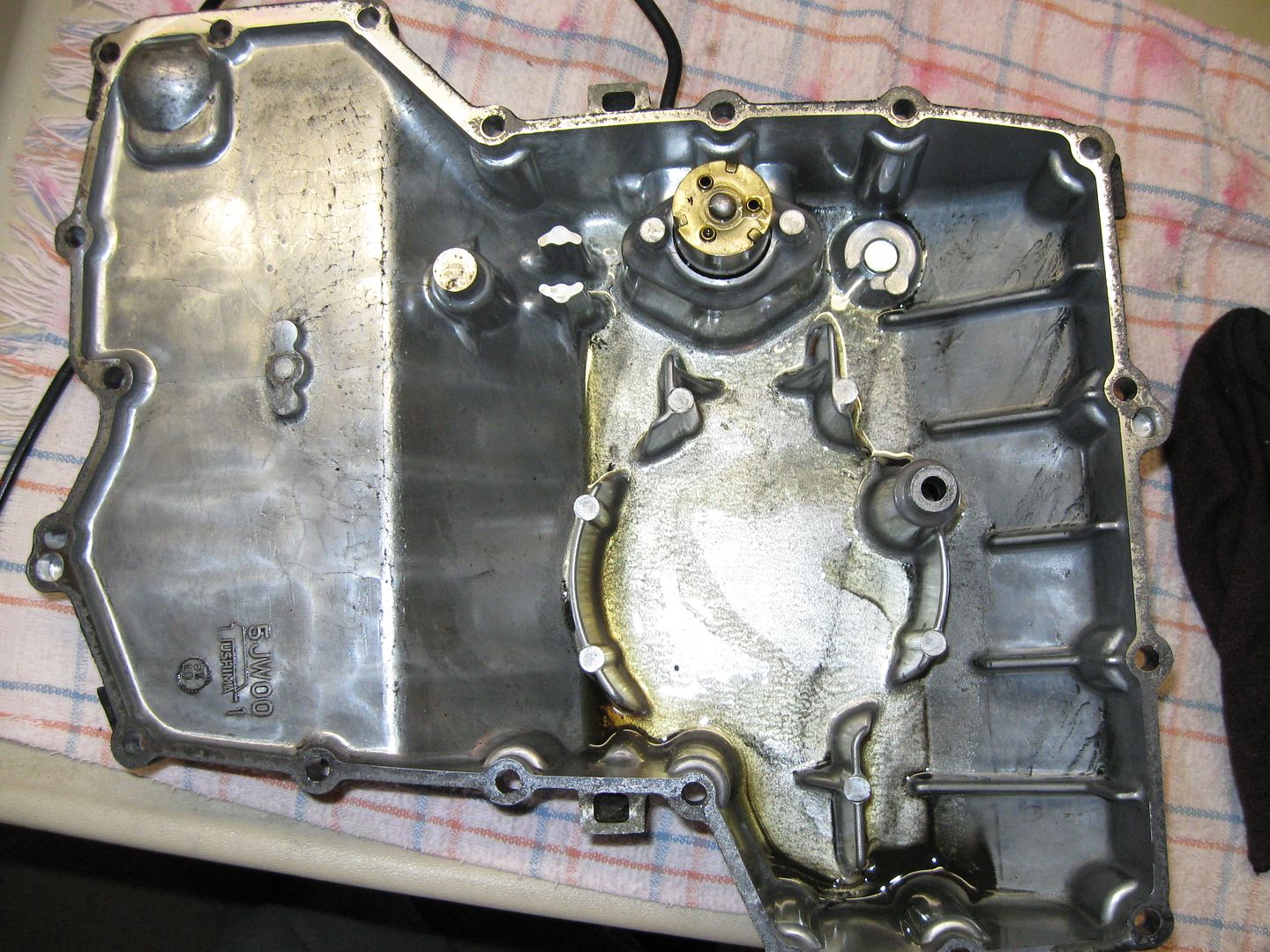

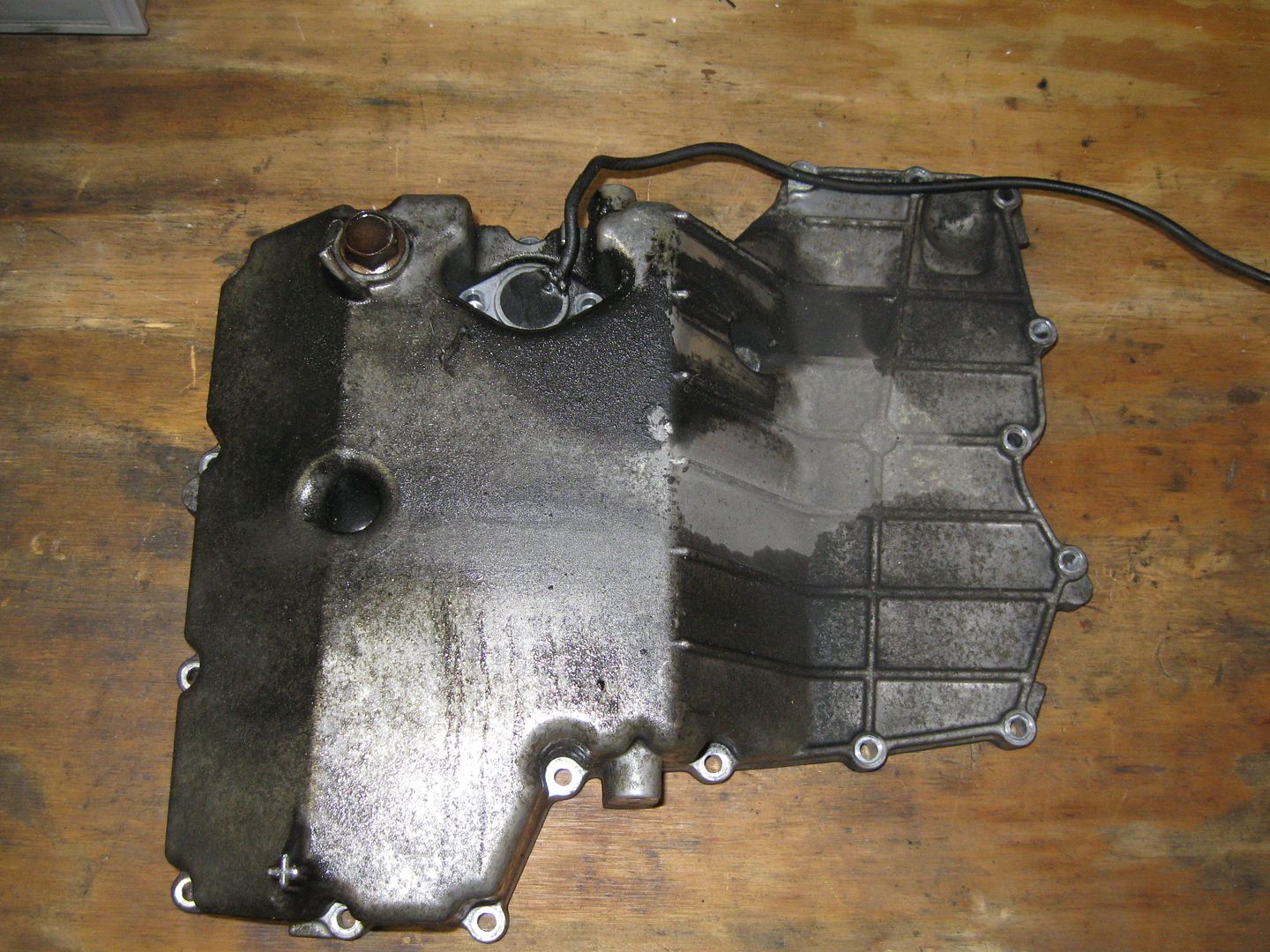

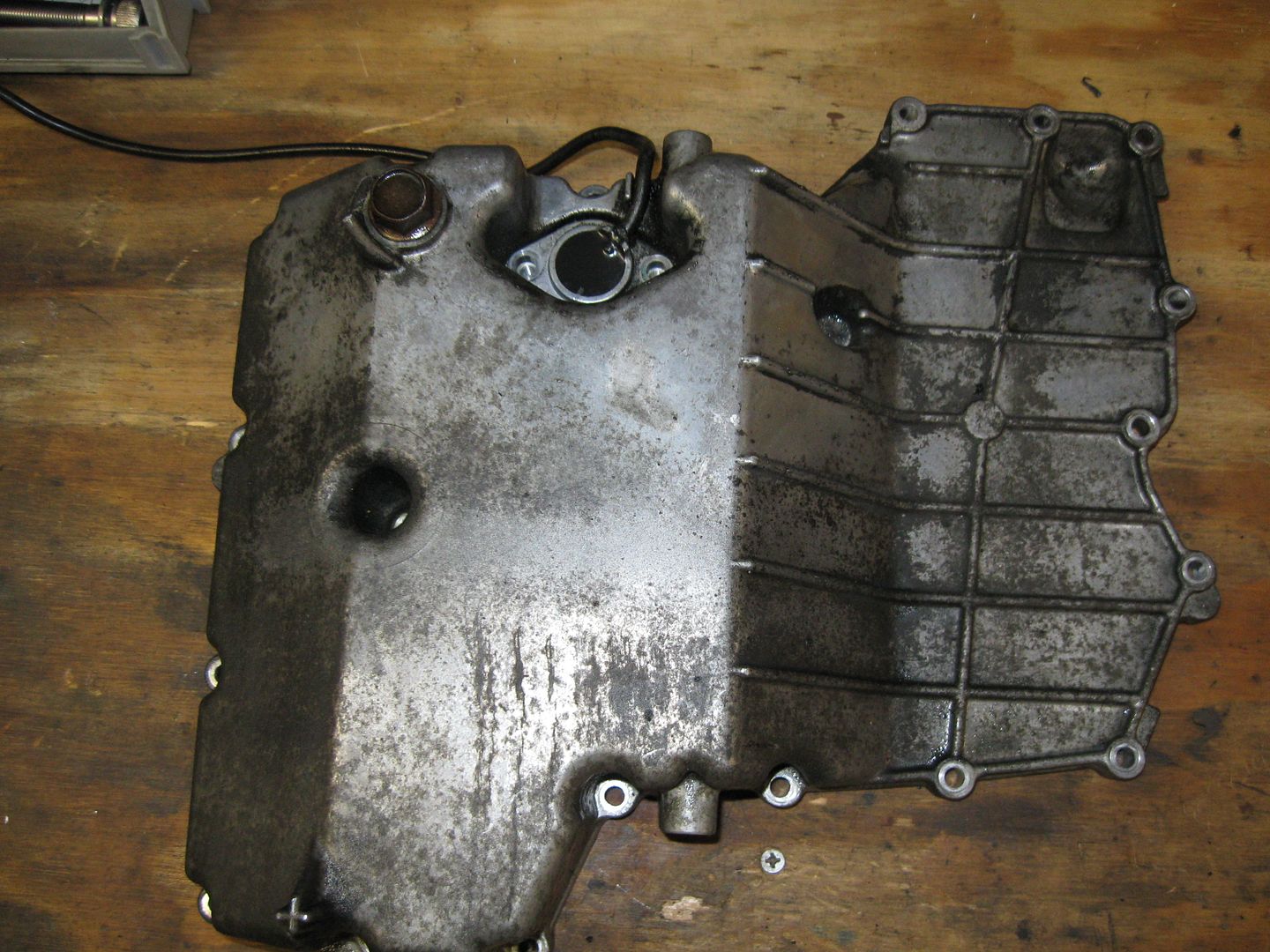

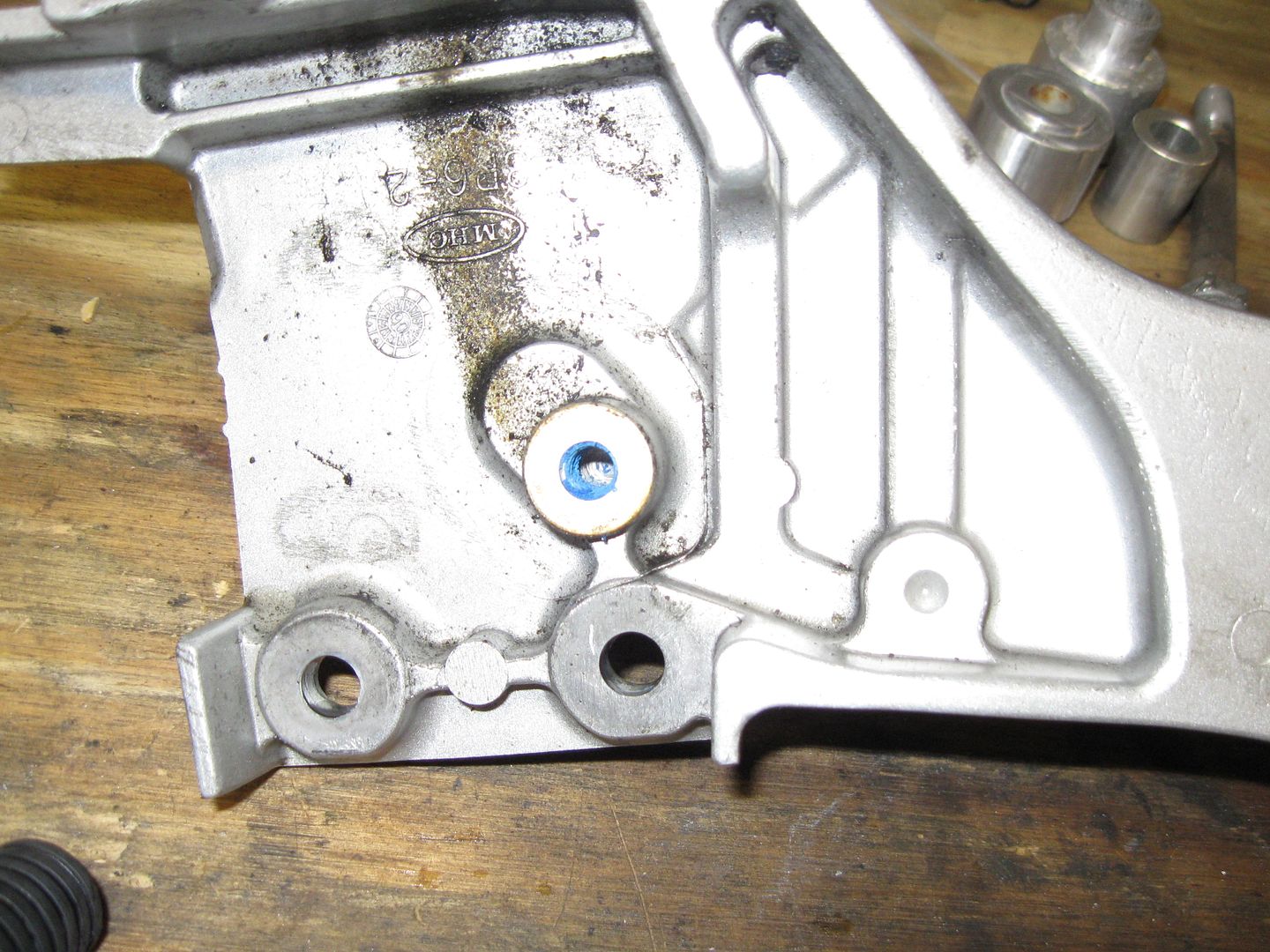

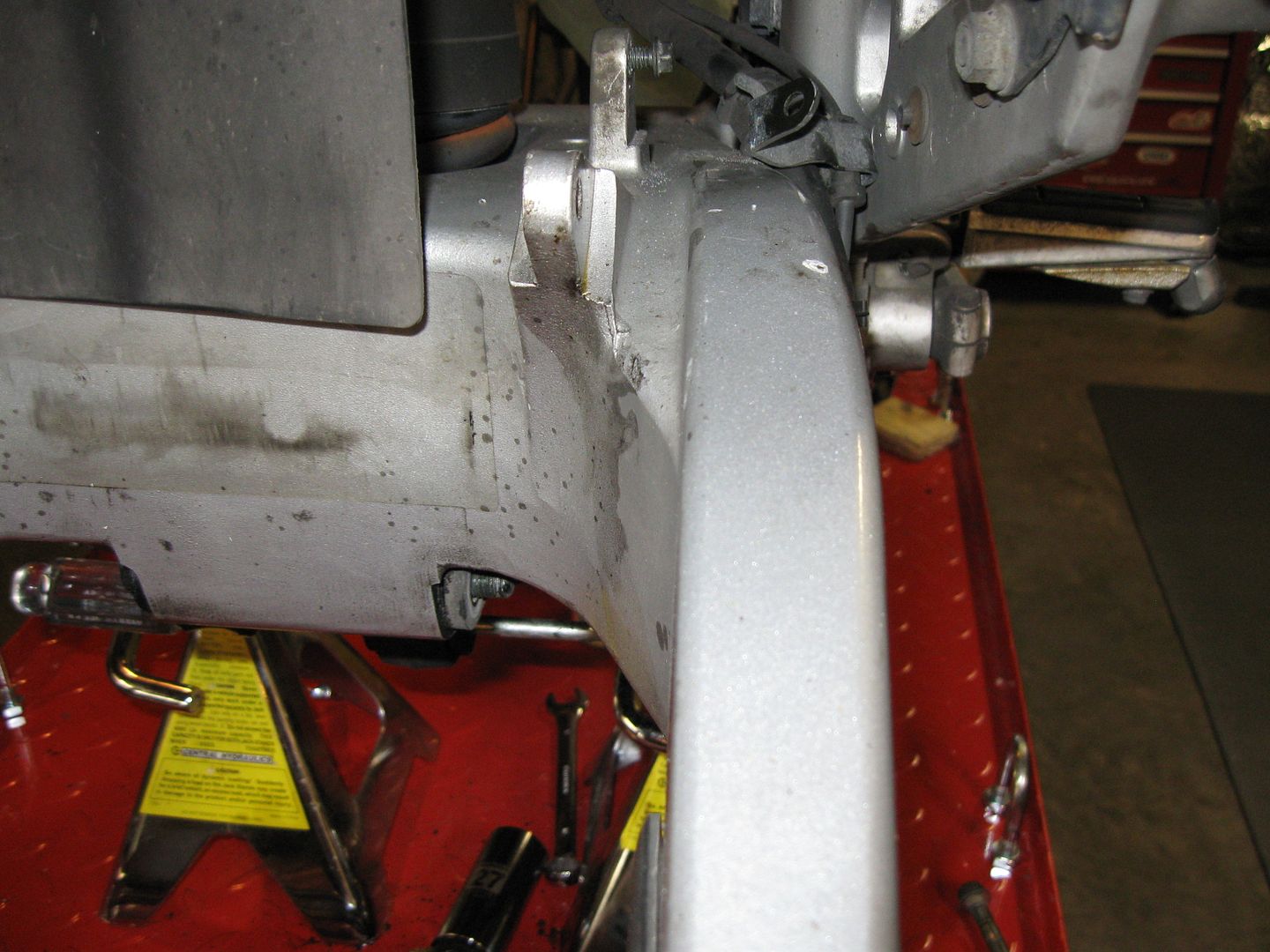

Here's a shot of the under side.

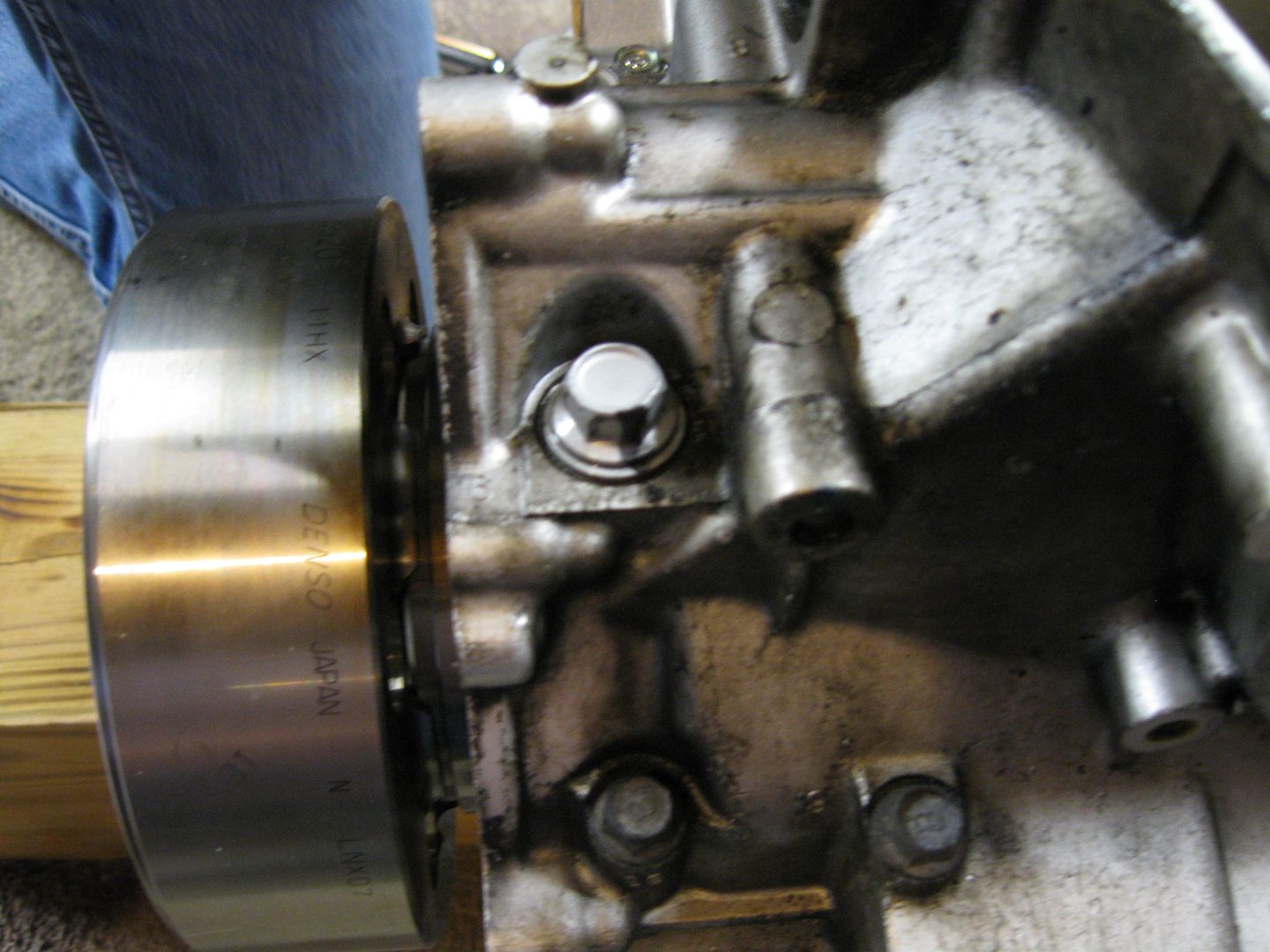

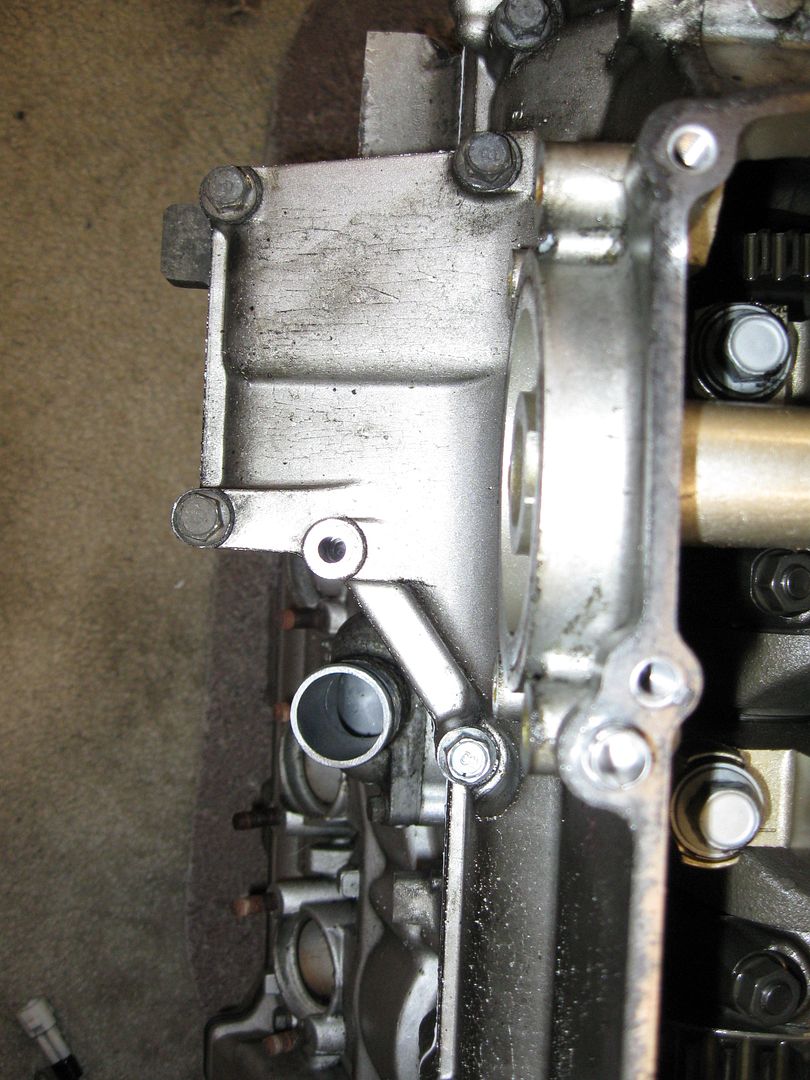

Centerstand bracket....mmmmK. Bolts and stuff there.................

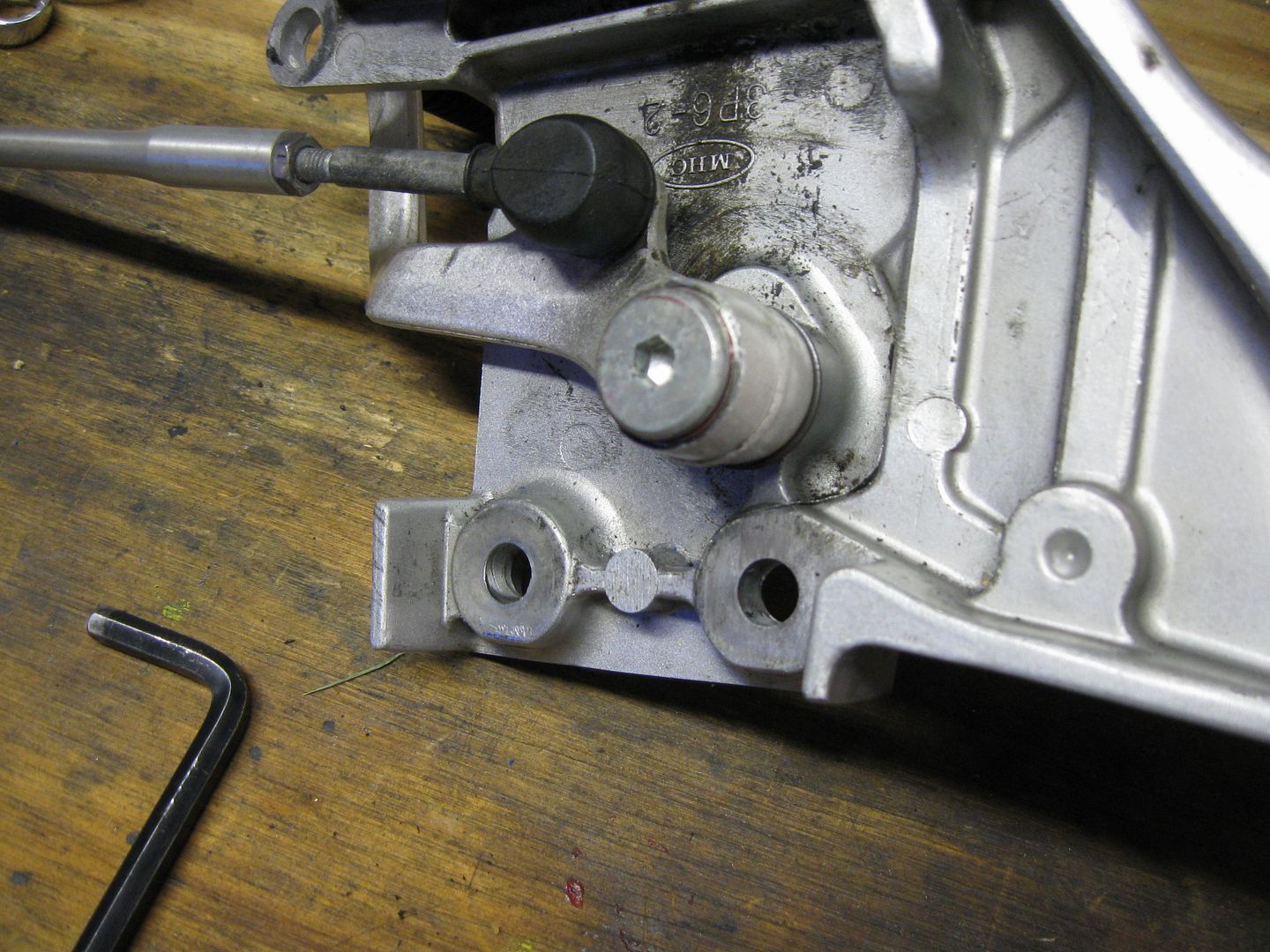

I need to remove that bolt and............... OH- - - - - K. I see the problem!

I'll come back to that. In the mean time the centerstand was removed.

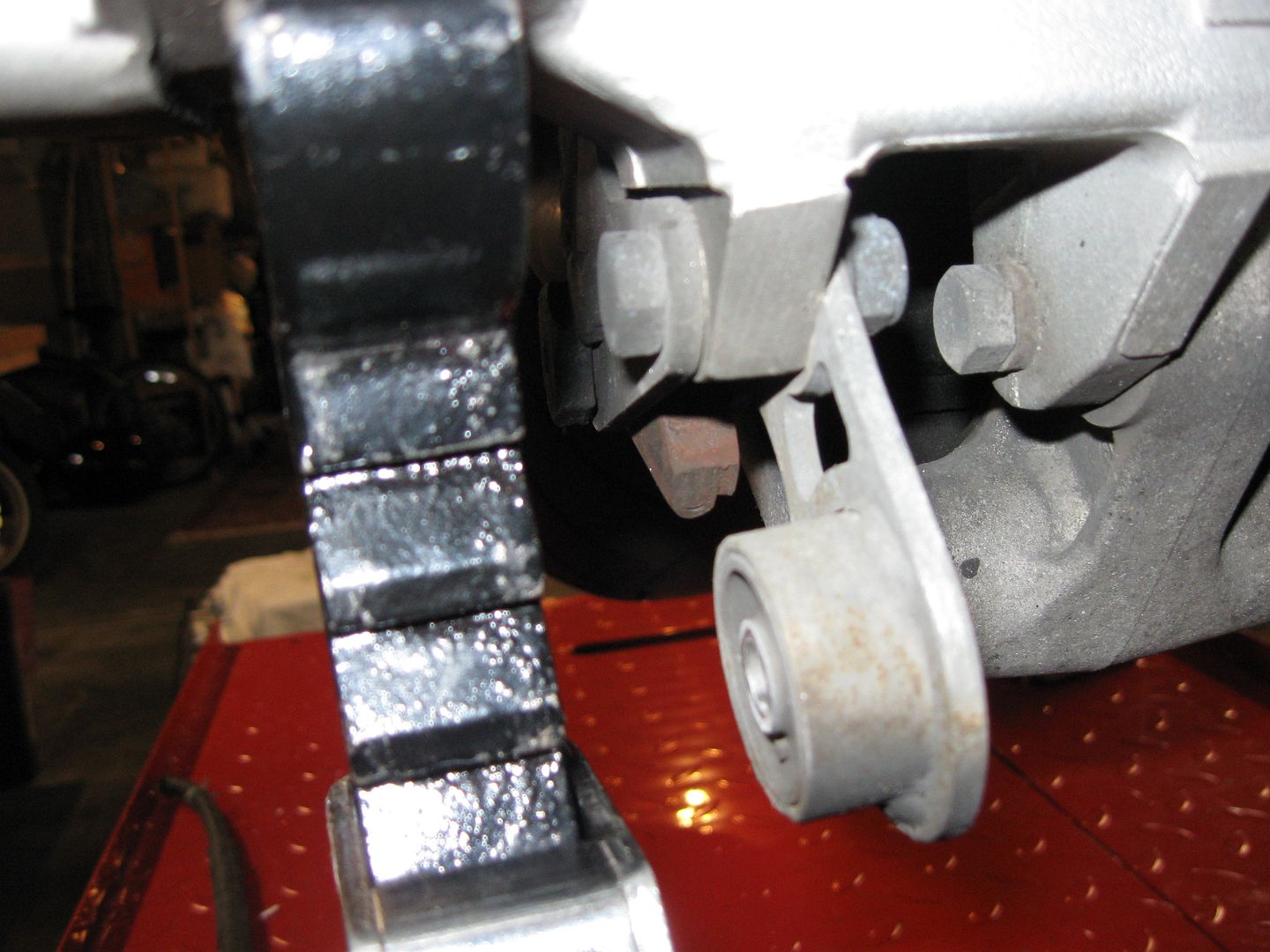

Suspension Mod of the Month I must say! EVERYONE will be doing this soon I'm SURE!!

Just a holder while I remove other bolts. As I said, it was puzzle to me.

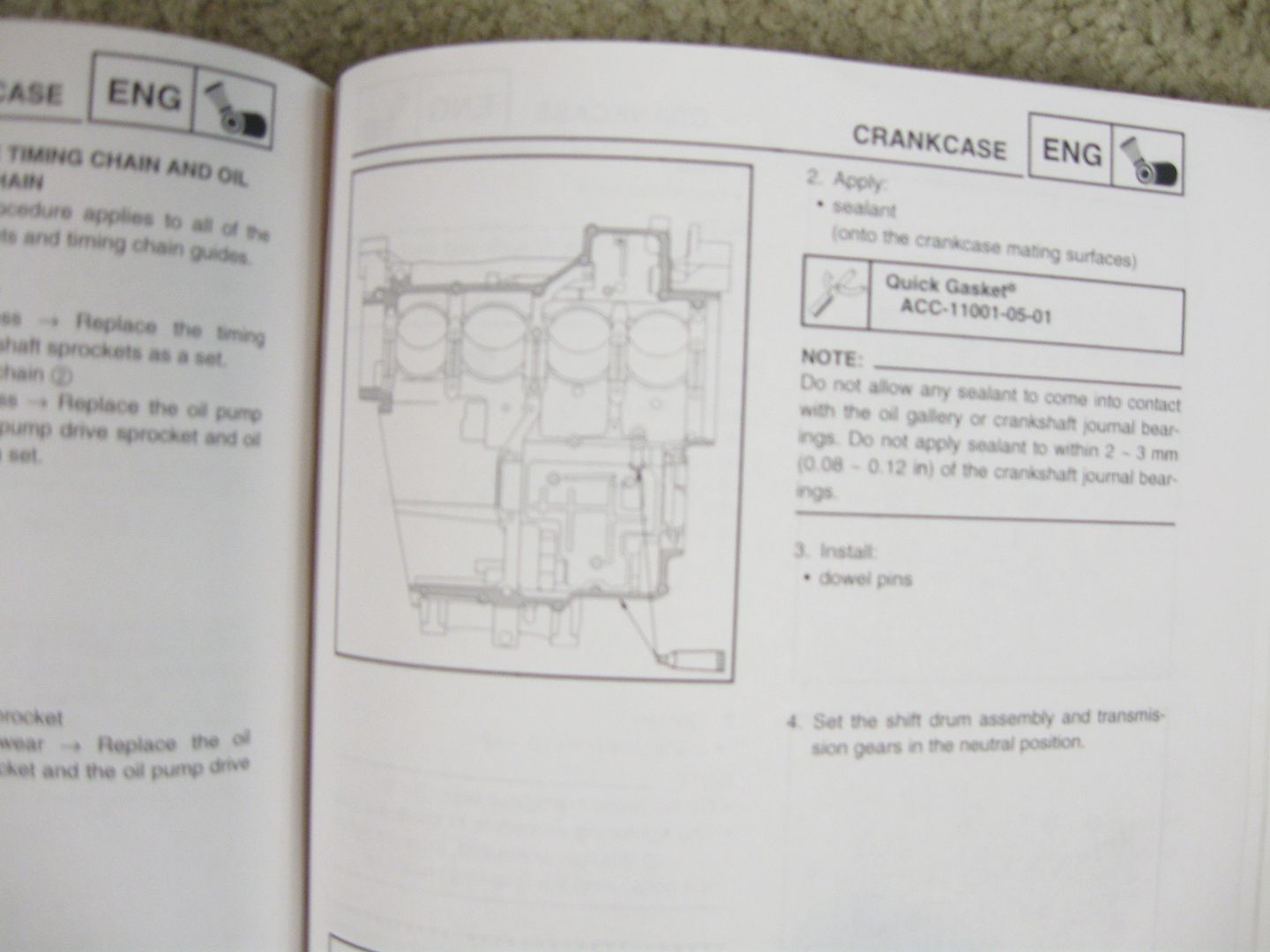

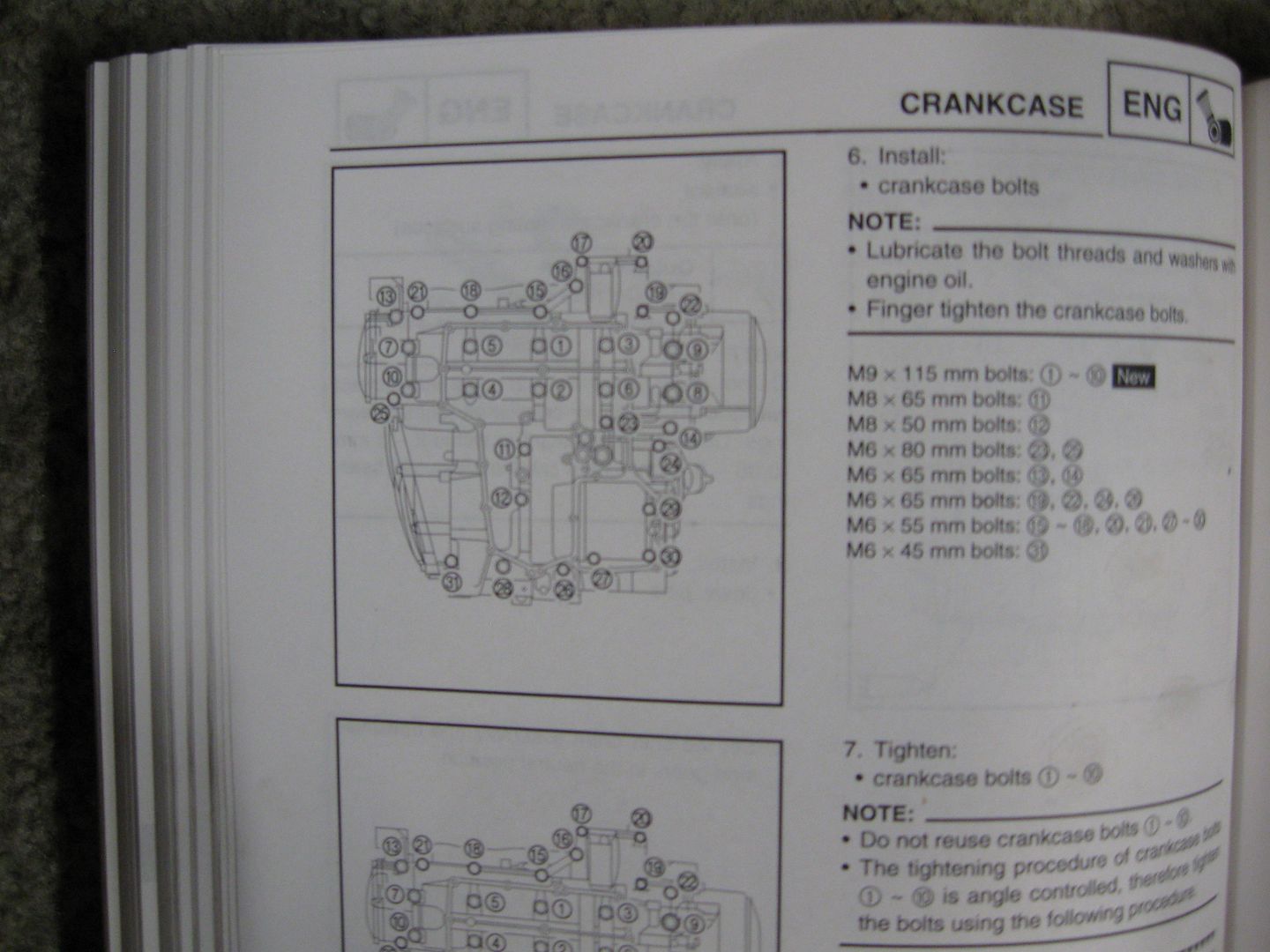

What? Shop Manual? You mean the book on the bench behind me? OH THAT THING! Well, if I used that now.....I'd um...... well, I would get grease on it! Yeah! and if that happens it'll.... well, you know, it'll lower it's re-sale value - er -something like that!

SHUT UP!

I hear ya'll giggling. (sigh)

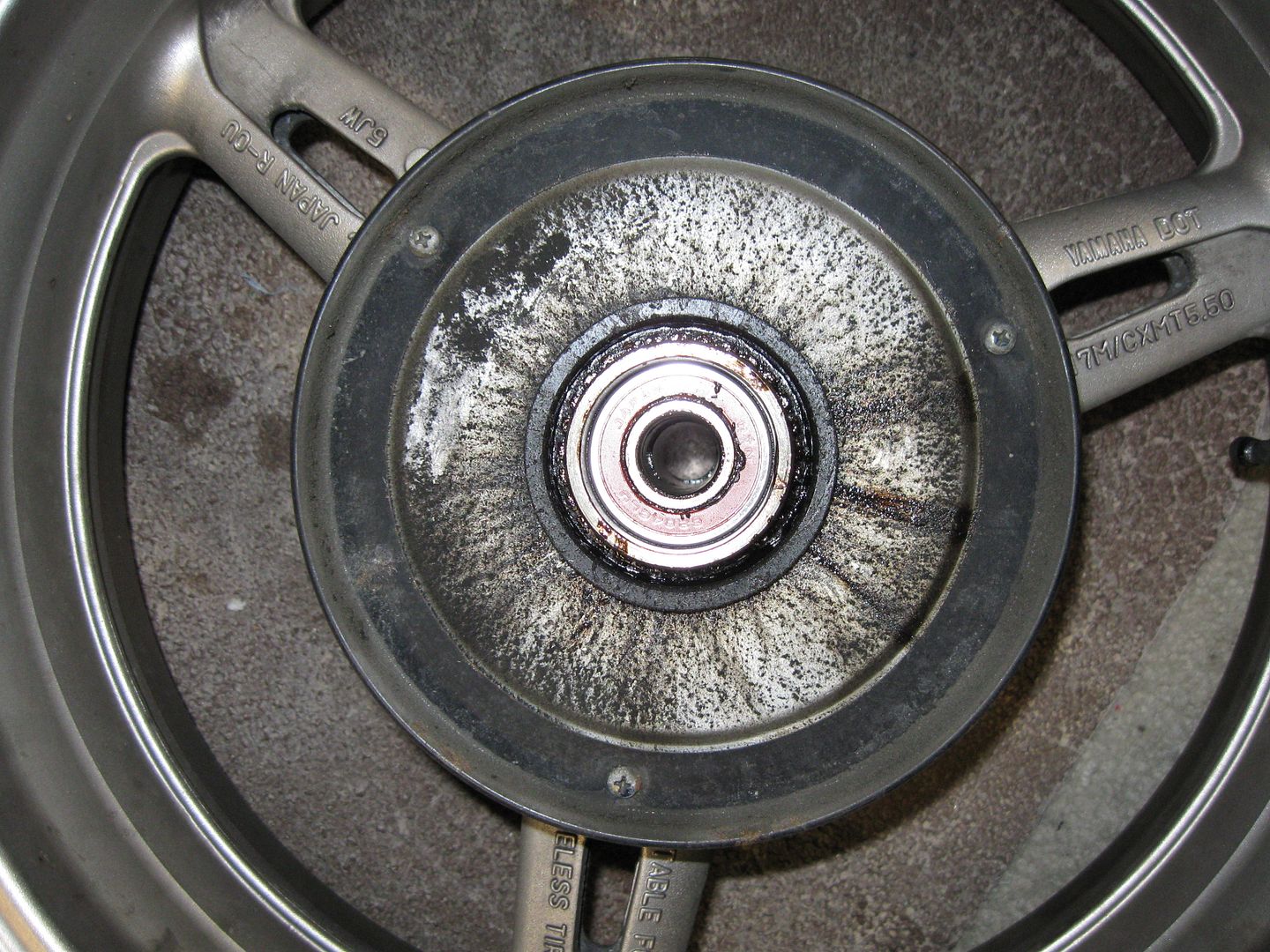

So, the wheel had to come off.

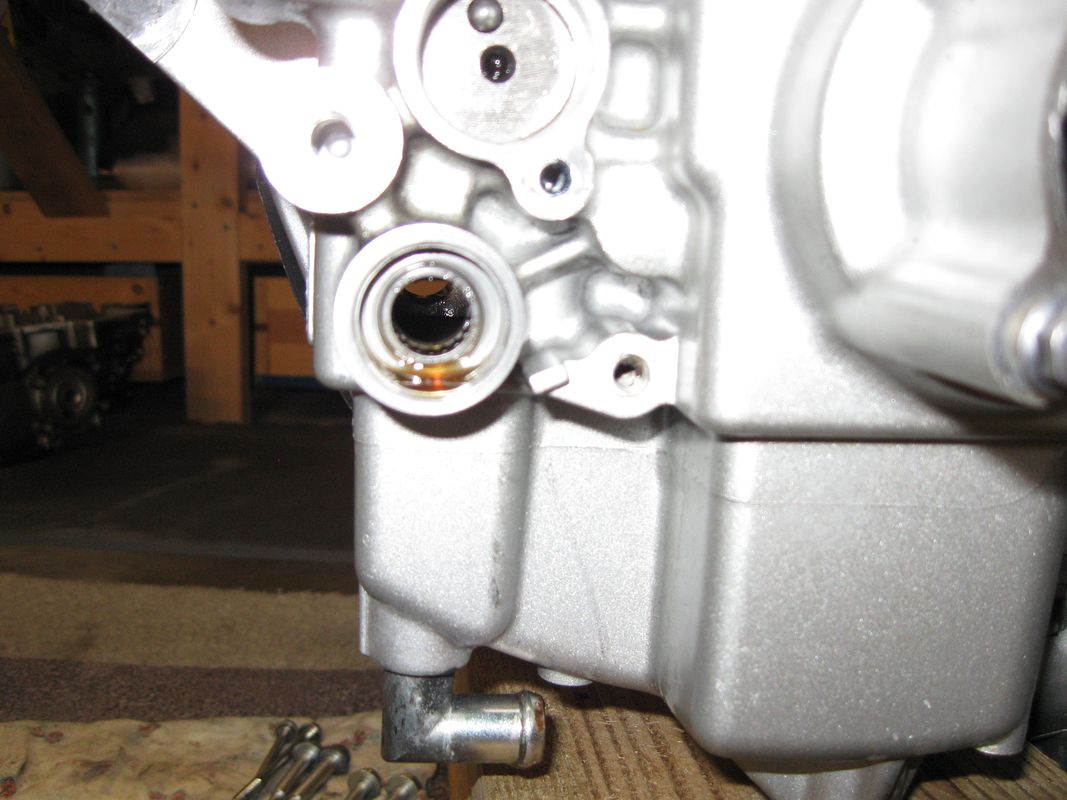

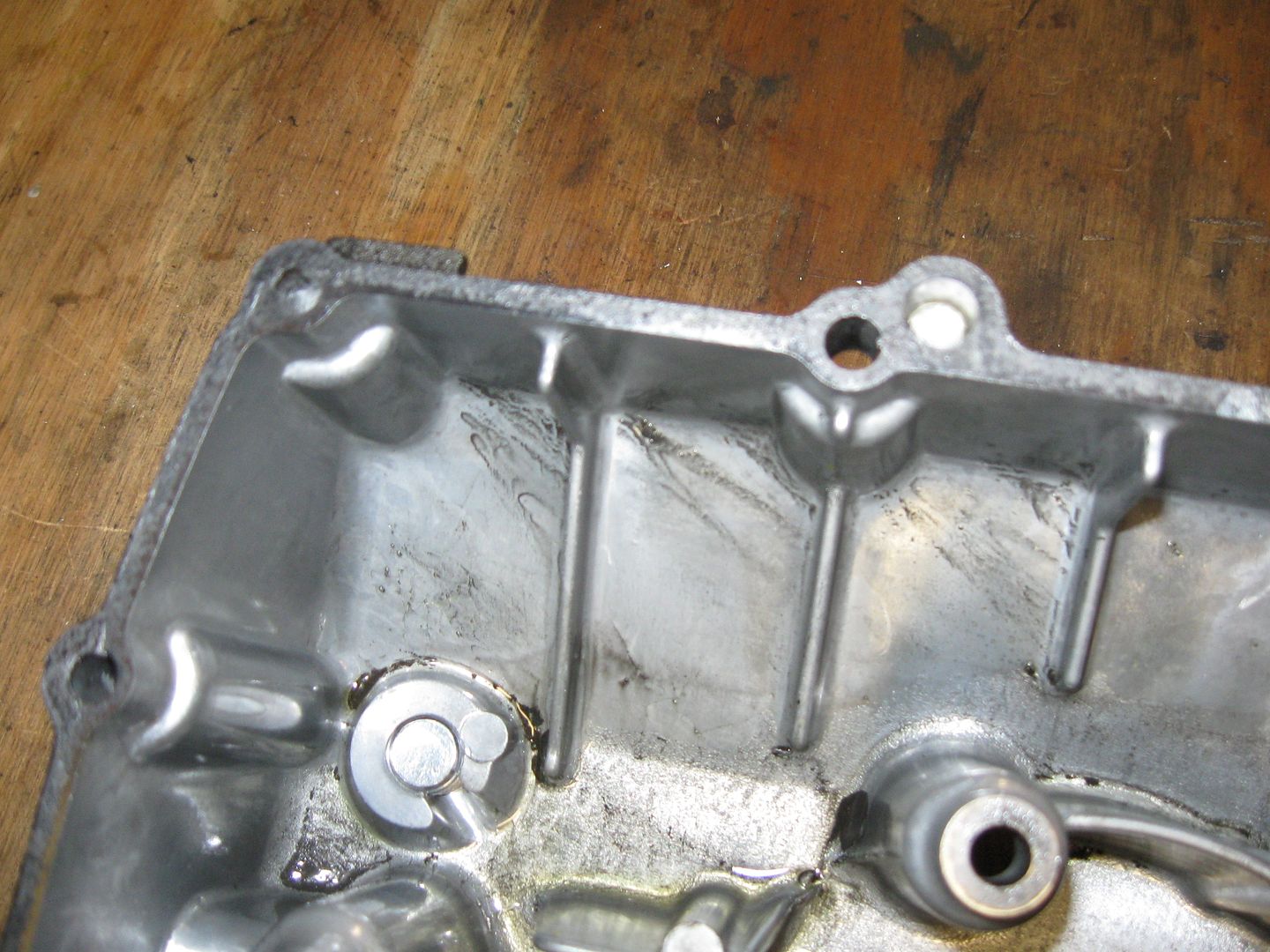

And I noticed in said earlier ignored book that there is something under those three little screws! What I call a cush drive or dampers. I wanted to see if they were in good shape.

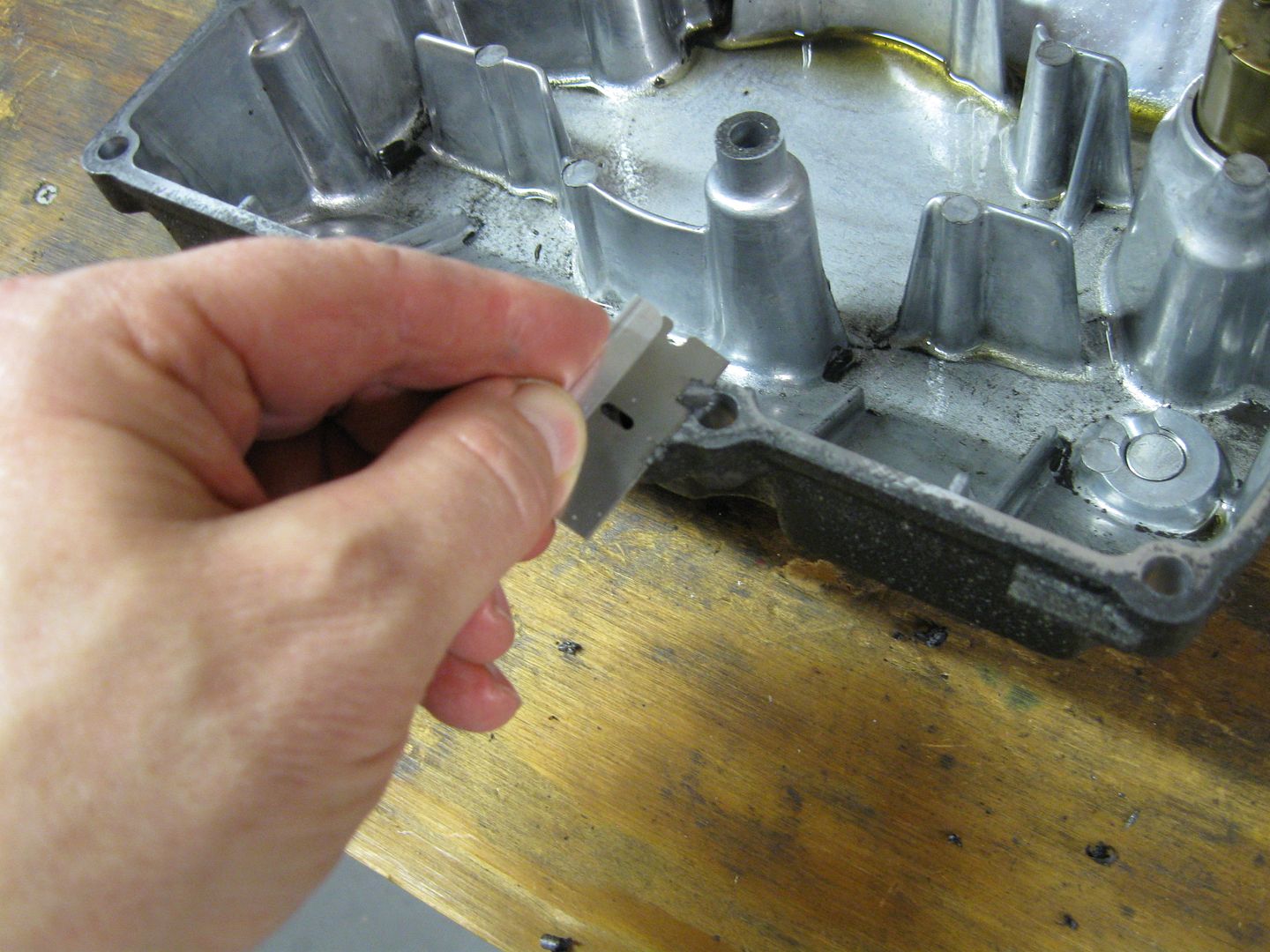

Cue Bane of my existence!!! The short of it? Well, take a look!

What's wrong with this picture? Top right looks ok..... the other two? Not so much! Yep, Loc-Tite. (note: As the manual calls for) I tried to remove the screws and one moved a bit and I almost stripped it but..... NO! SNAP goes the head! The other was less forgiving. I attempted an impact screwdriver and .... BAM! Right off! I try not to swear.... but this is what the rear wheel got -

.

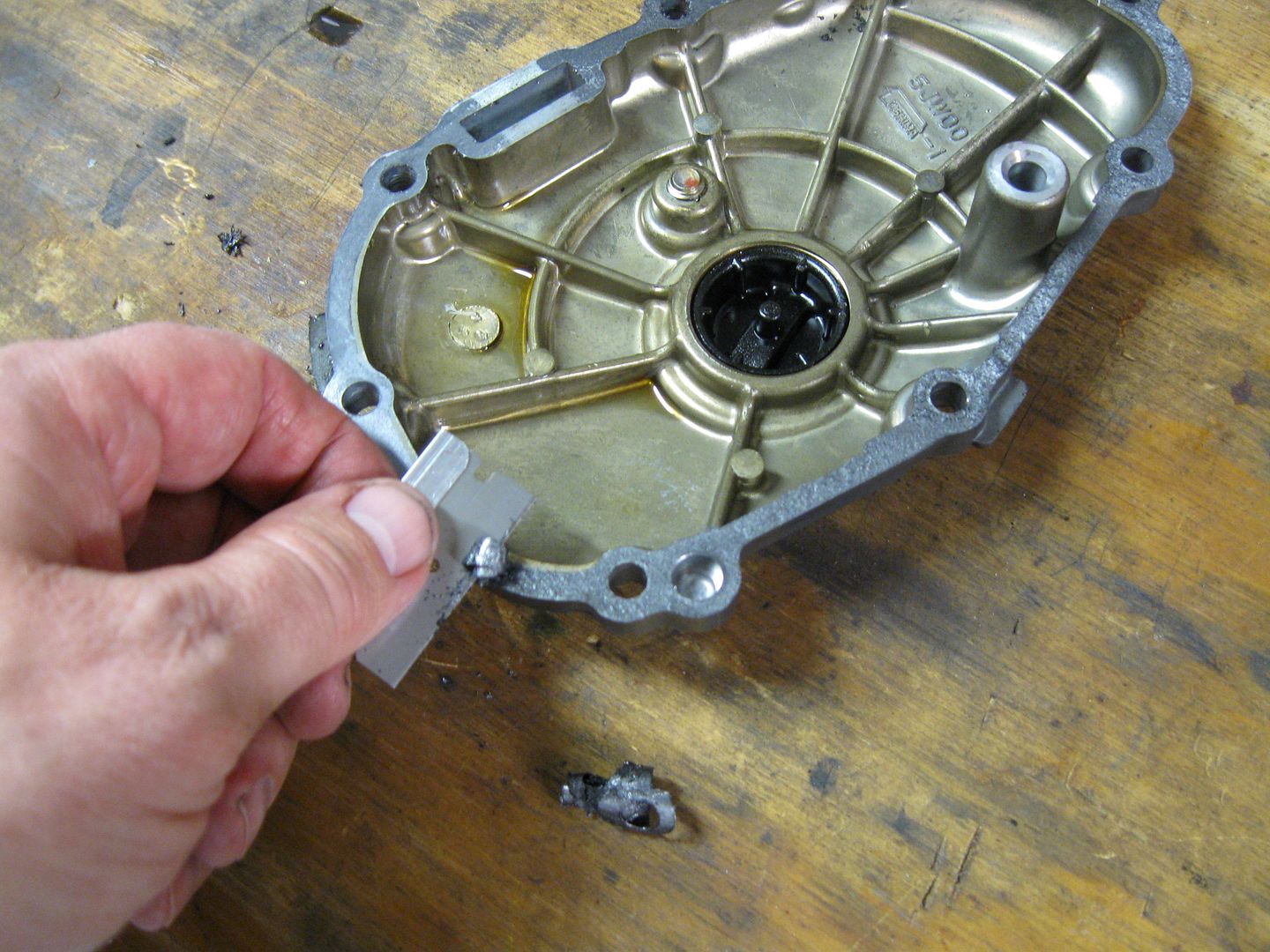

Ok, so a drill and tap is in my future. Film at 11.... in a few weeks most likely. Well, the ring is off, let's see what's inside!

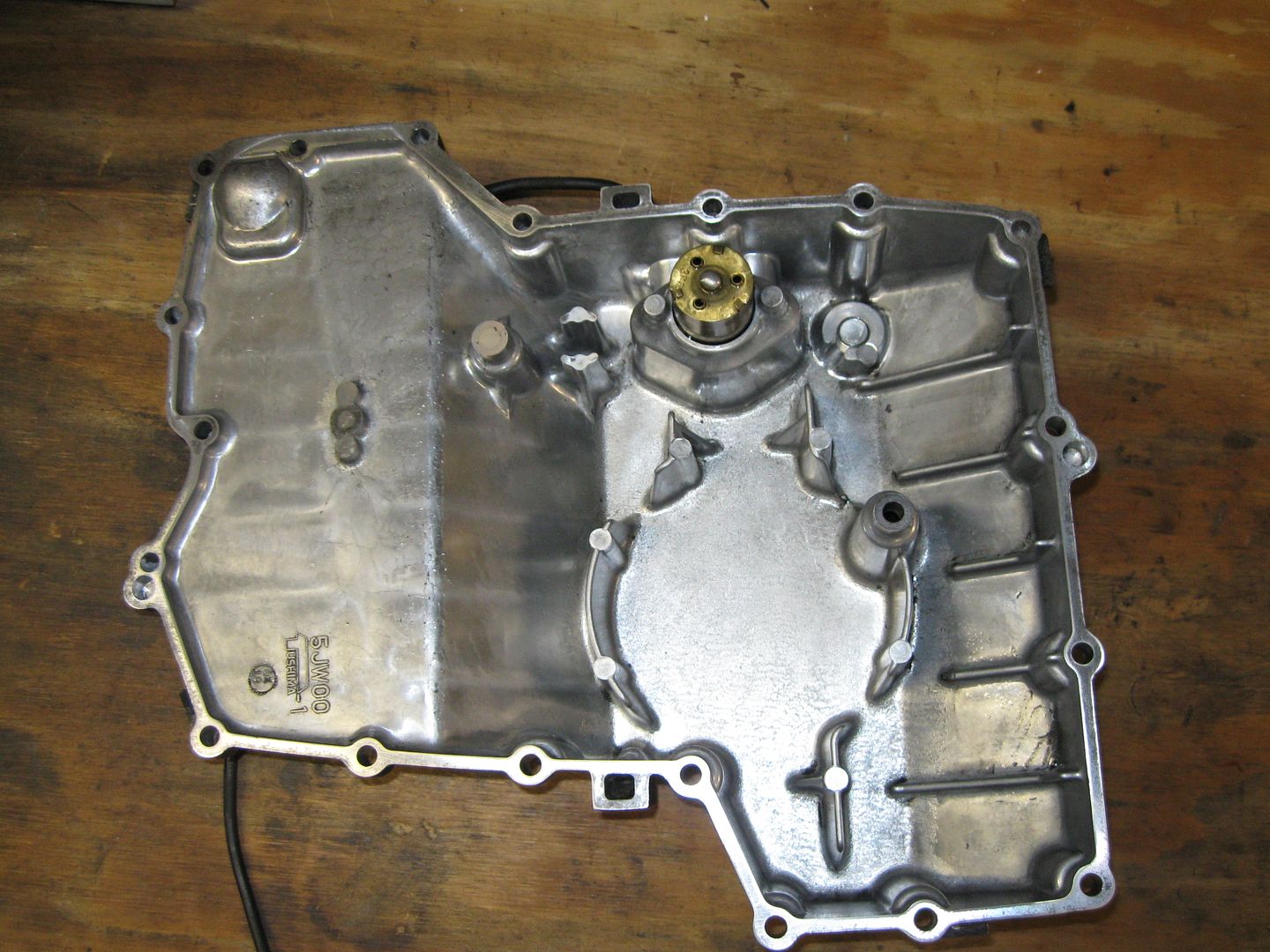

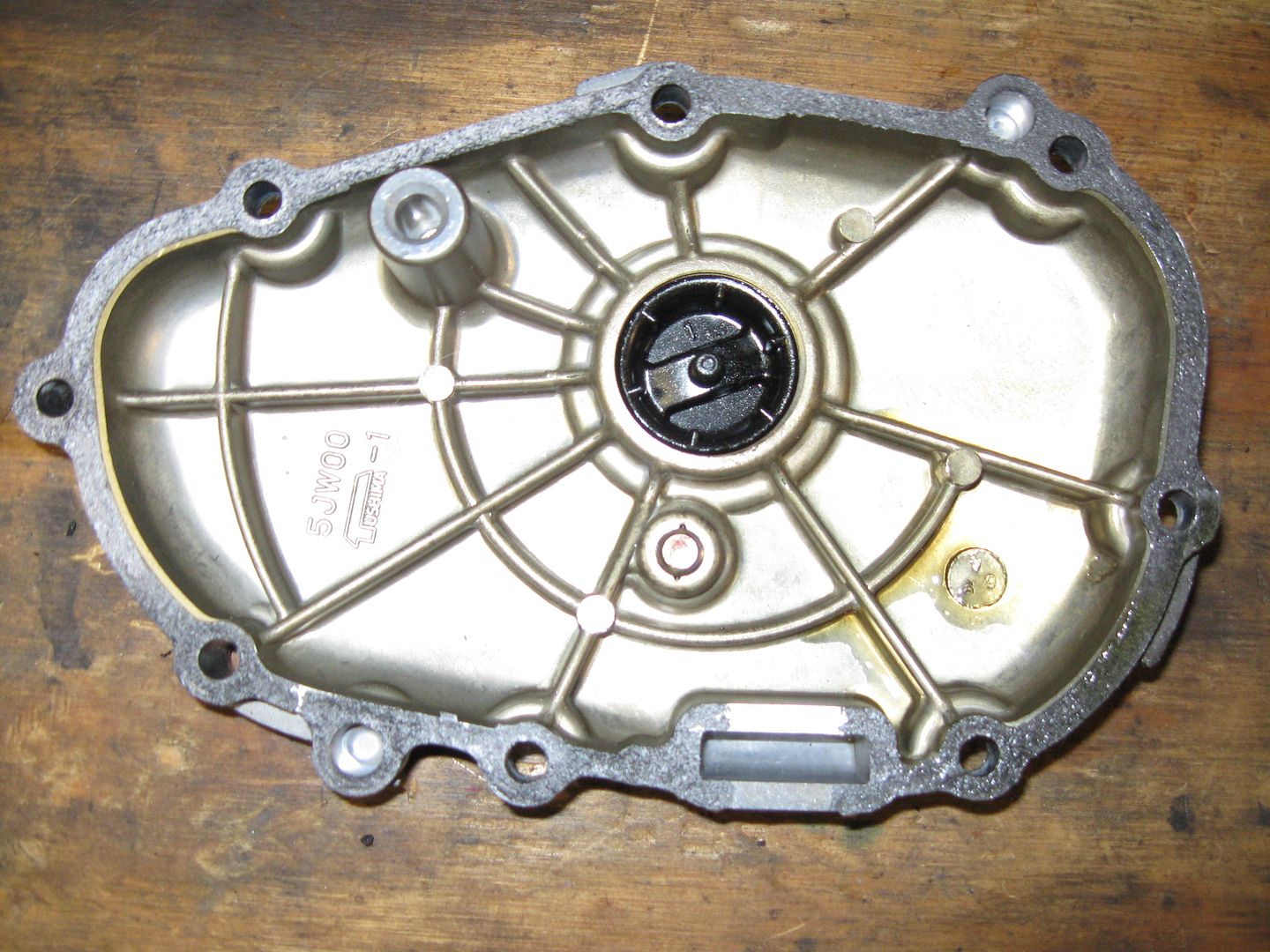

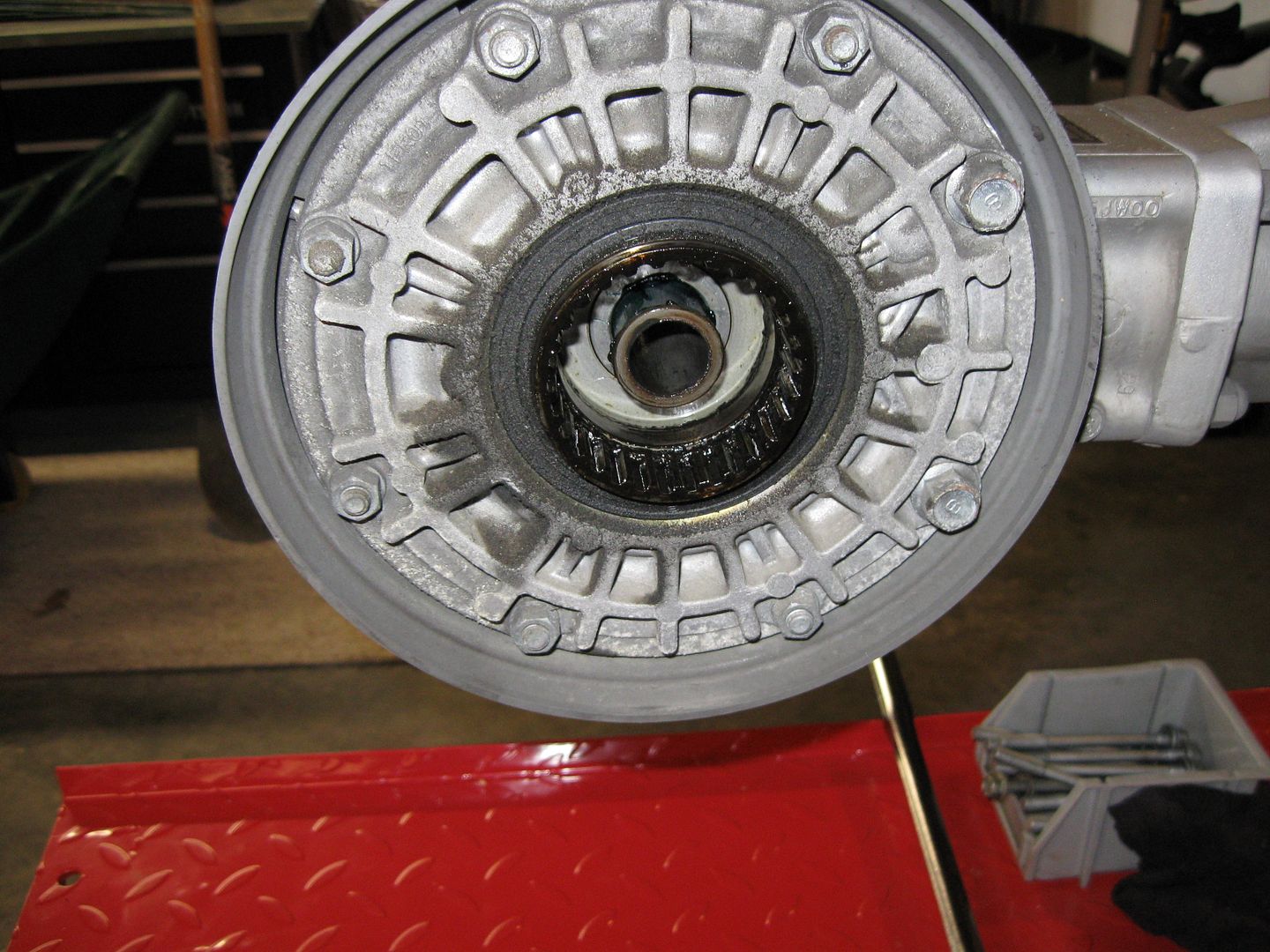

Dang near new looking to me! Here's what the "lid" part looks like:

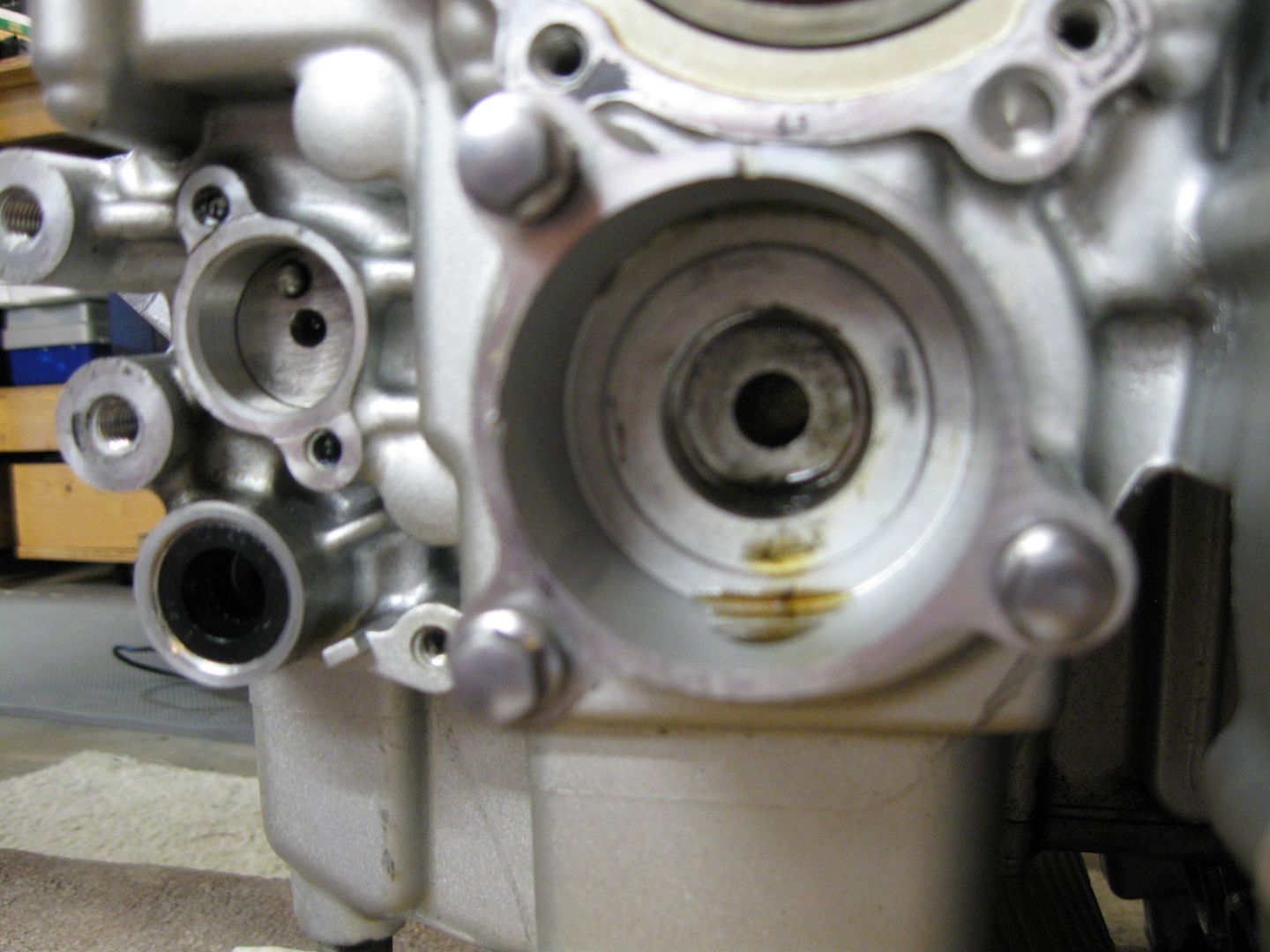

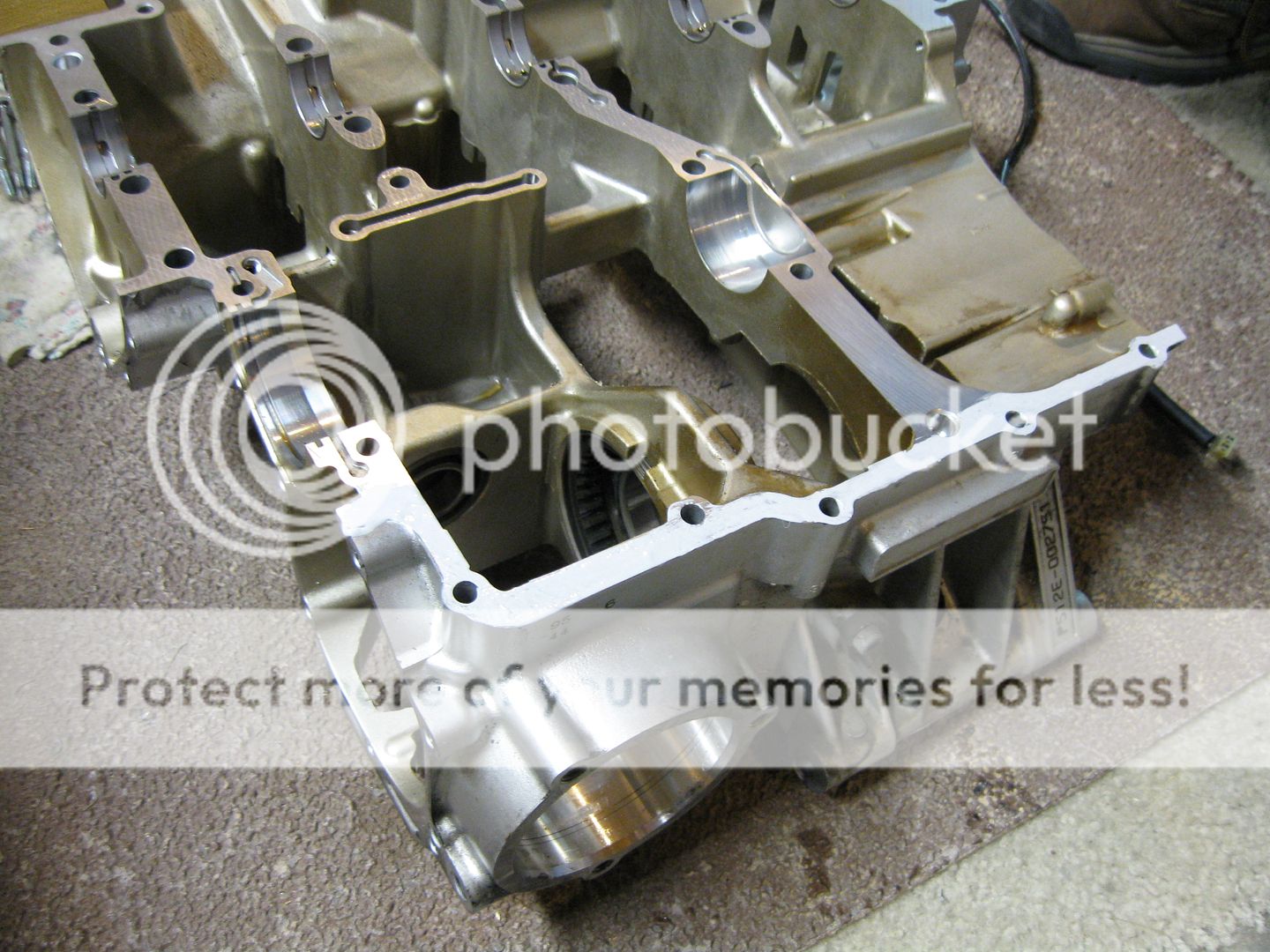

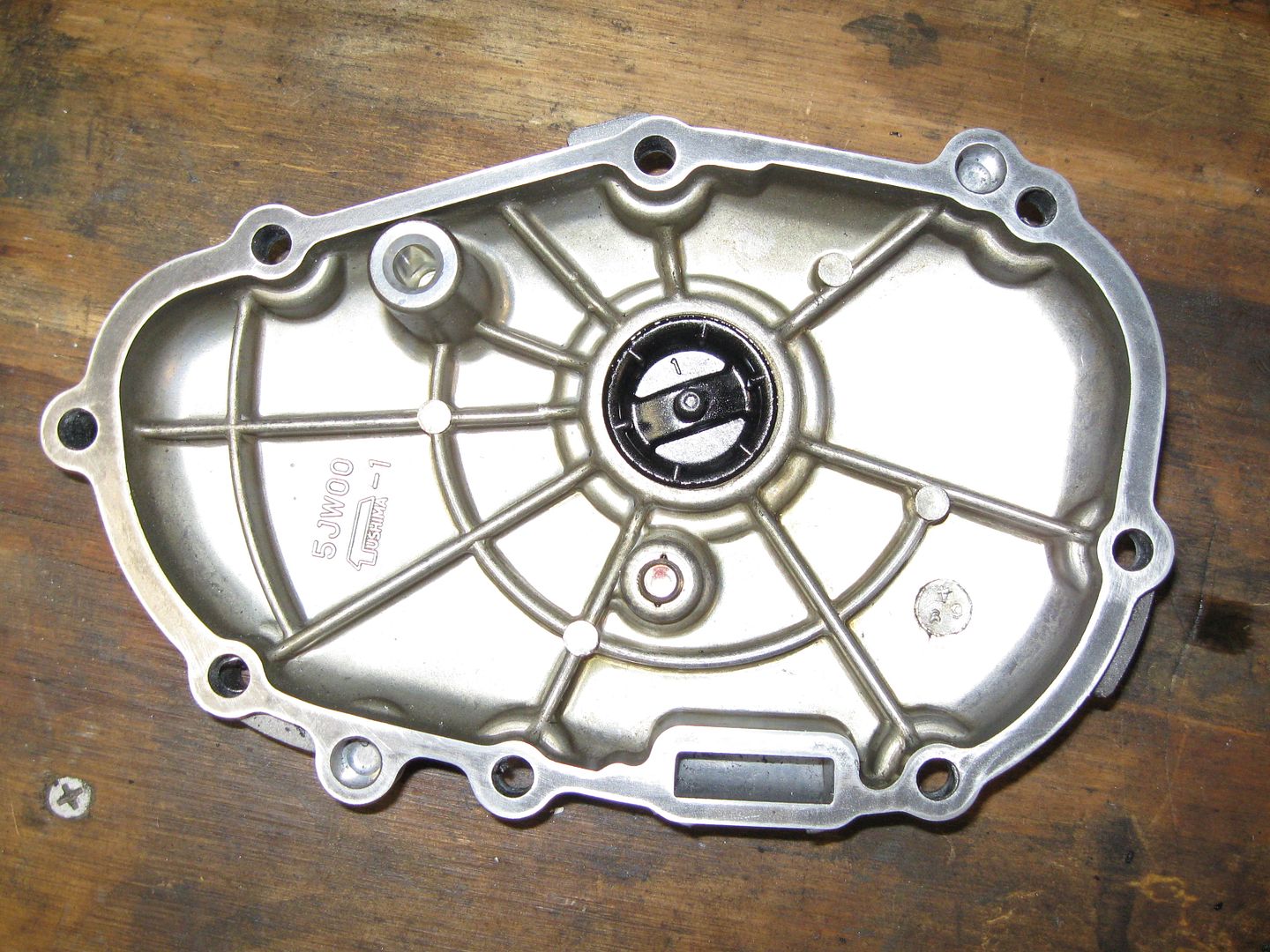

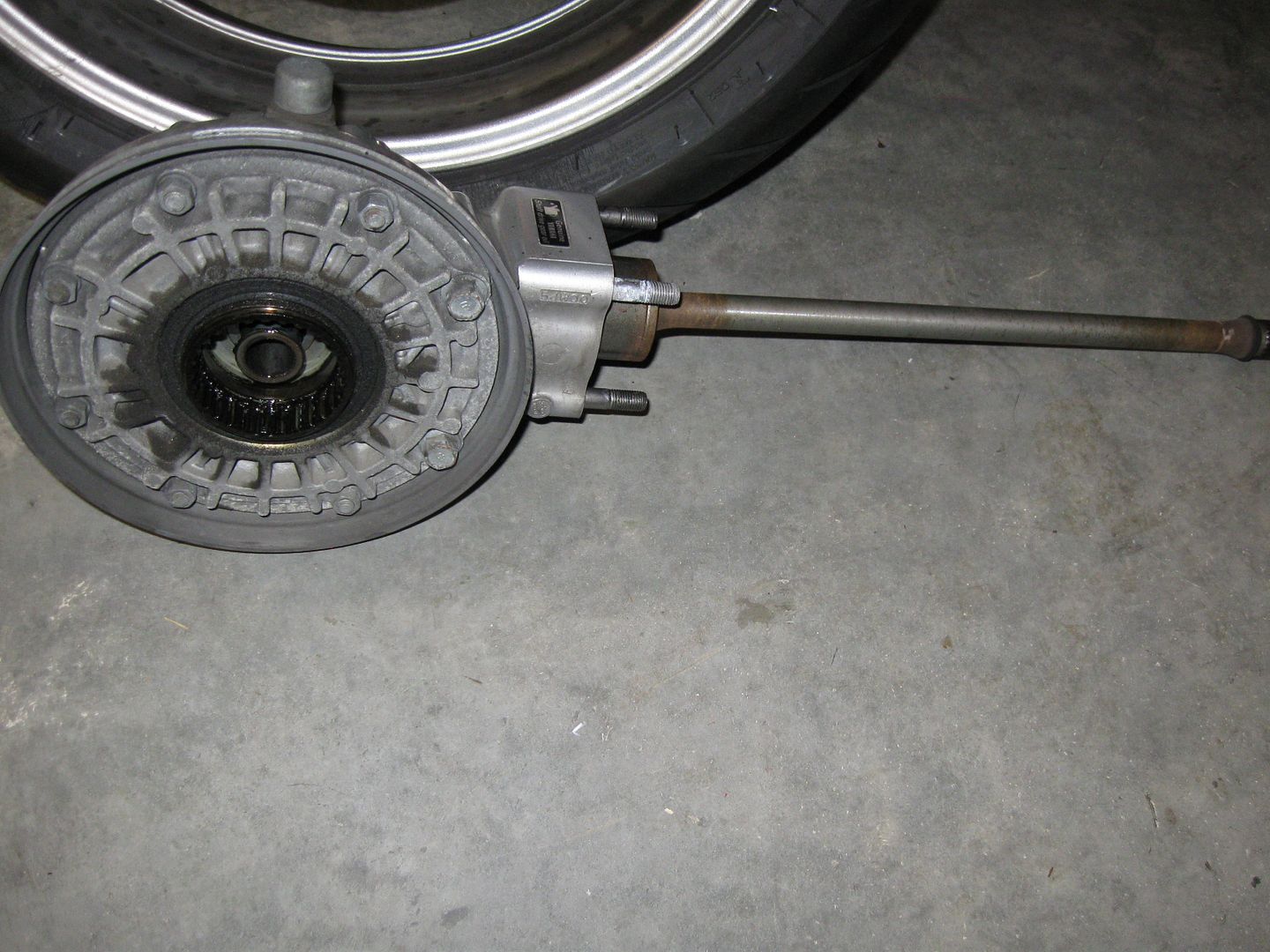

So the final drive piece comes off without any drama and I set that aside:

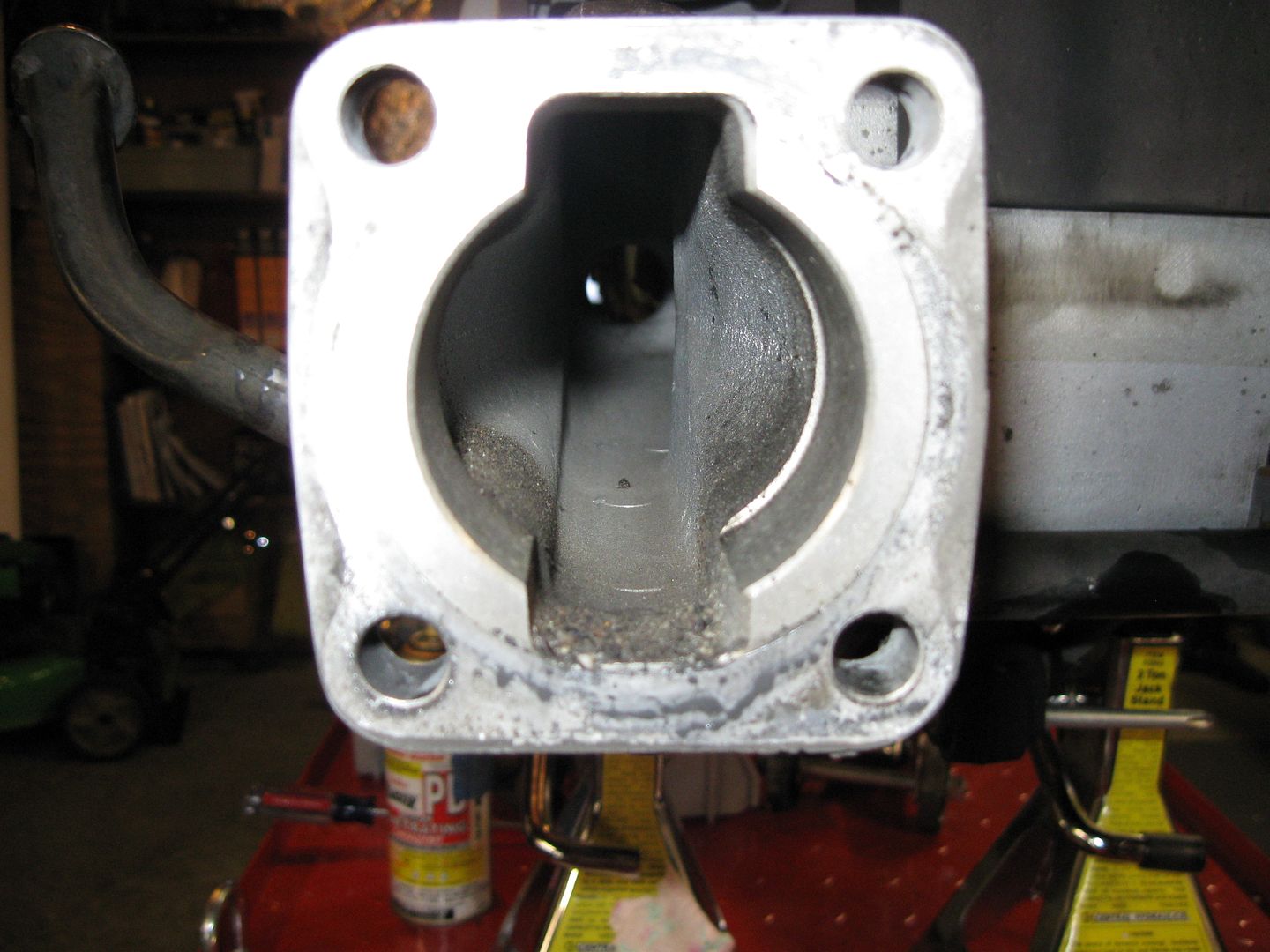

Take a stare down the business end of a shaft drive!

Yeah, it did nothing for me too.

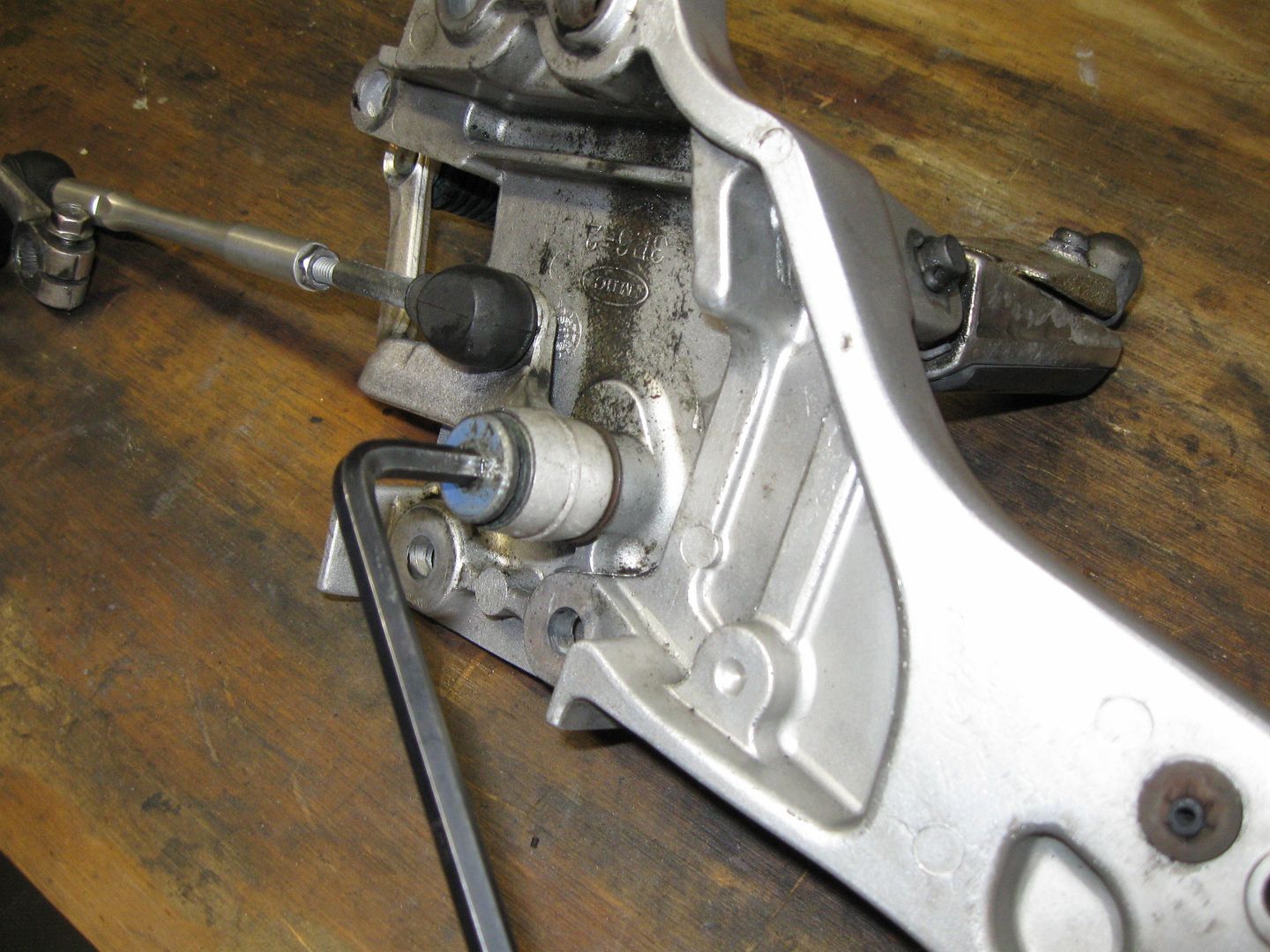

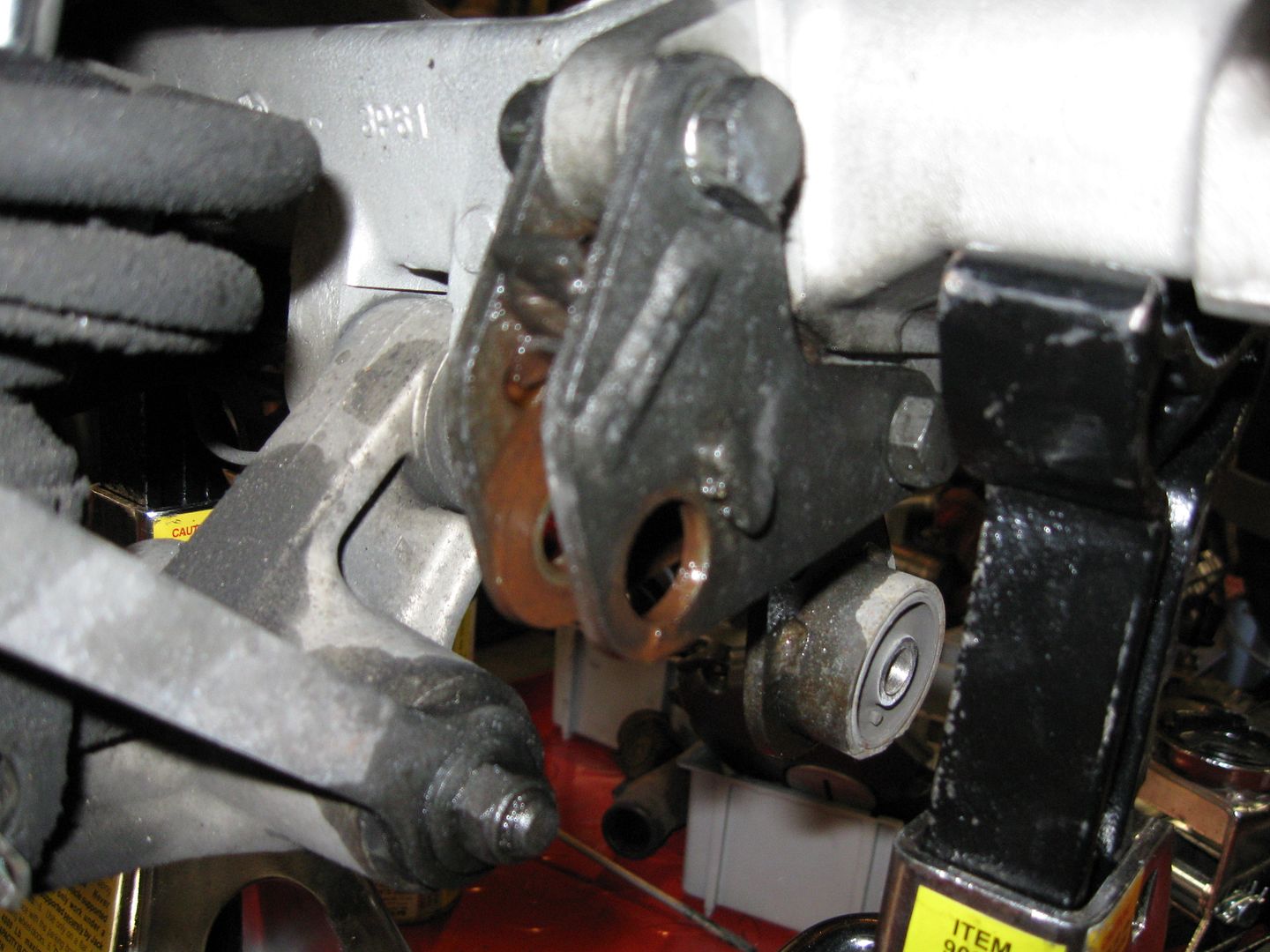

With the wheel off, I moved the brake and anti-lock brake lines/wires out of the way. I had to remove the bracket.

That's about where I left it. There's a few more parts that got removed and I'll pickup there on my next post.

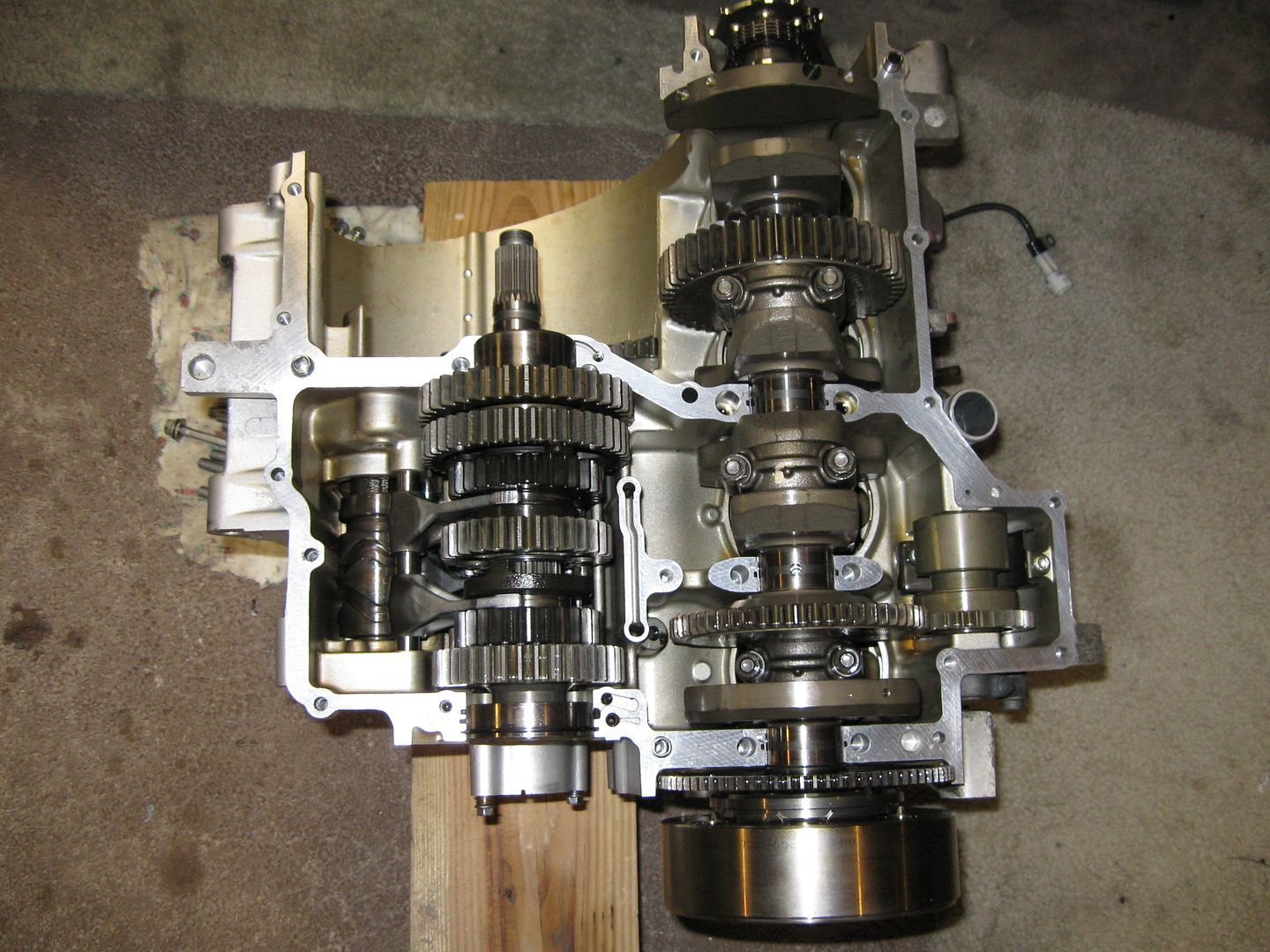

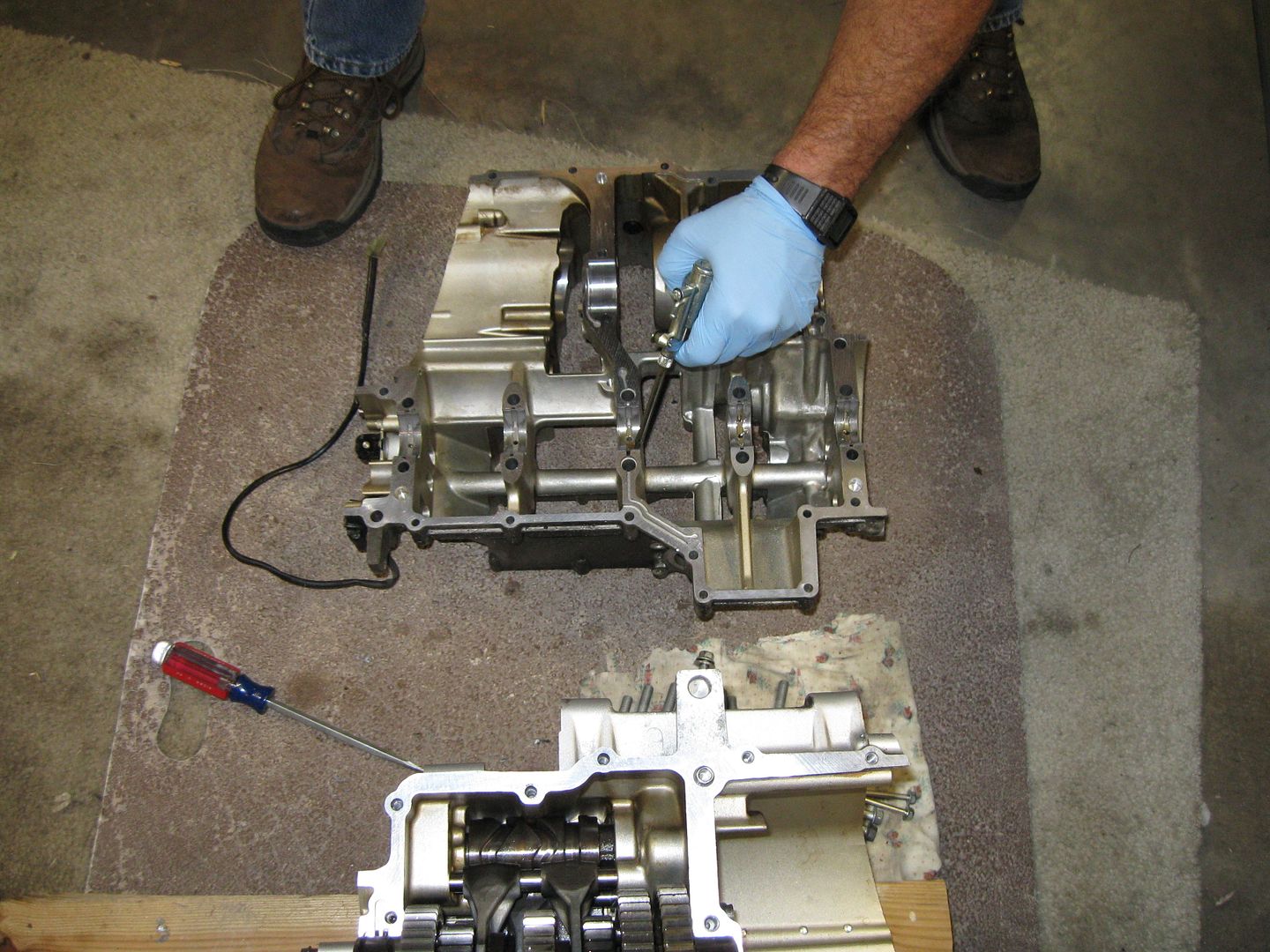

I took a look at the empty shell of what .paul spent about 5+ years and 60K miles riding, stood back and thought "What have I gotten myself in to?!"

It's a process. A labor of love. An education. And I'm REALLY looking forward to my first ride when it's all buttoned up!!

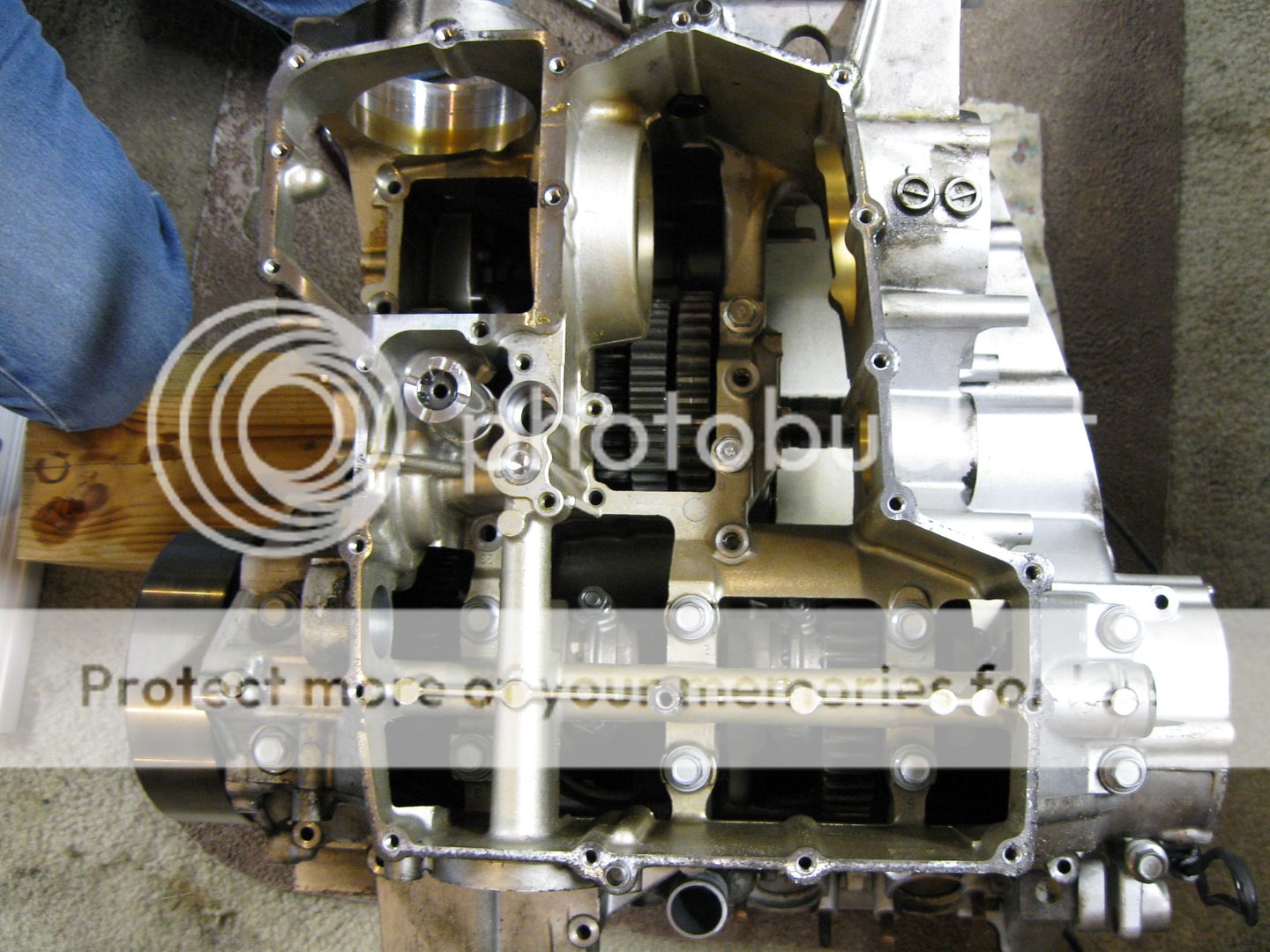

By the way, Doug did stop by Monday evening after he spent all day on the brakes of two cars and fighting Volvo Turbo oil leaks and surveyed what we have to do. He said of the engine "This will all go back together in about an hour or so."

I don't doubt him, but I'm not going to time it either! I keep telling him, I want it done correctly! Not quickly!

Thanks for tuning in to another installment.