Streethawk

Well-known member

Very nice Paul! Somewhere there's a GS crying because you didn't buy it!

So it snowed here in Maryland.... and other parts of the North and Northeast. (sigh)

A look out the basement window

My workplace is opening 4 hours late because of this "storm" here! - I was born and raised here and still think everyone gets Mental when it snows. From the way they drive to the impulse to buy toilet paper and milk...

I dunno...

I dunno...

So in anticipation of this "snow event" (3-4 inches) I moved some friends down to the basement so I could put the cage in the garage.

The Vulcan is the wifes.

The VFR.

And my first bike, purchased over 20 years ago new. My HawkGT.

As stated earlier, I wanted to pretty up the frame sliders.

Interesting how one got more faded than the other. Sidestand side gets more shade I guess.

So I made an attempt at prepping them with some 500 grit sanding.

After the first couple coats...

I just keep hitting it with one quick spray on each side, then walk away. Been doing that for about a week now. As of now, they are looking pretty good! I just hope they stay that way for a while.

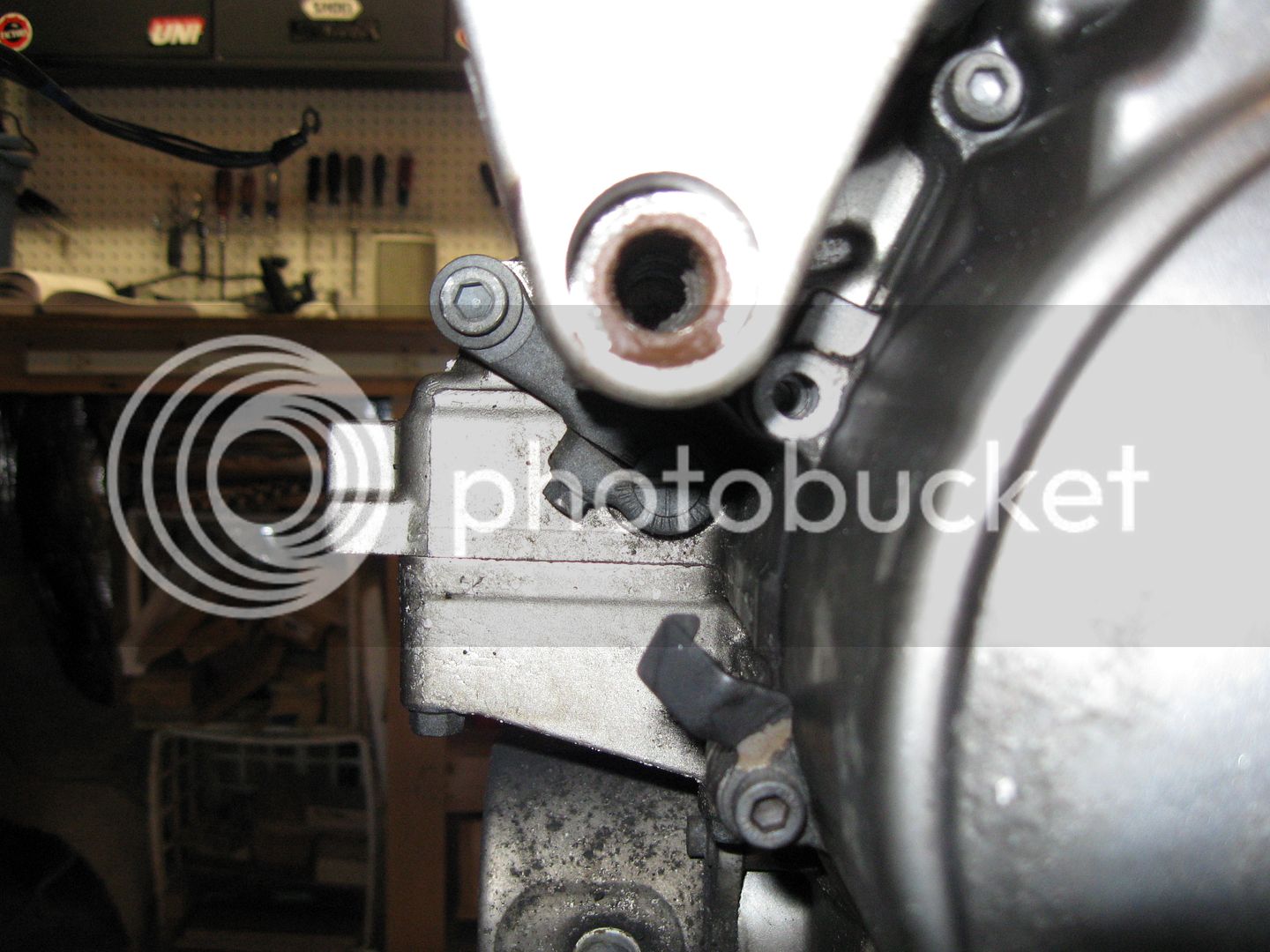

So I moved the exhaust to the bench to attempt to break free the O2 sensor, then treat with anti-seize. Just some preventative maintenance.

Let's just say it's not working out so well so far! I've been dribbling PB Blaster on the threads a couple times a day for a week now. I also tried a little heat, but my problem is I only have an adjustable wrench to grab it. I'll have to see if I can get a better tool.

That's all I have for now. I'll try to keep updates more frequent until she's running!

So it snowed here in Maryland.... and other parts of the North and Northeast. (sigh)

A look out the basement window

My workplace is opening 4 hours late because of this "storm" here! - I was born and raised here and still think everyone gets Mental when it snows. From the way they drive to the impulse to buy toilet paper and milk...

So in anticipation of this "snow event" (3-4 inches) I moved some friends down to the basement so I could put the cage in the garage.

The Vulcan is the wifes.

The VFR.

And my first bike, purchased over 20 years ago new. My HawkGT.

As stated earlier, I wanted to pretty up the frame sliders.

Interesting how one got more faded than the other. Sidestand side gets more shade I guess.

So I made an attempt at prepping them with some 500 grit sanding.

After the first couple coats...

I just keep hitting it with one quick spray on each side, then walk away. Been doing that for about a week now. As of now, they are looking pretty good! I just hope they stay that way for a while.

So I moved the exhaust to the bench to attempt to break free the O2 sensor, then treat with anti-seize. Just some preventative maintenance.

Let's just say it's not working out so well so far! I've been dribbling PB Blaster on the threads a couple times a day for a week now. I also tried a little heat, but my problem is I only have an adjustable wrench to grab it. I'll have to see if I can get a better tool.

That's all I have for now. I'll try to keep updates more frequent until she's running!