SkooterG

Purveyor of Crooked Facts

Damn, I love a good mental masturbation! Can't believe I have missed this one so far. Freaking work!

So here's my $.02.

I don't think it matters either way.

Way back in 2004 when installing my Wilbers shock on my first 04 FJR I came across this stuff and thought it was congealed grease. As I was removing it, I realized it was supposed to be there. Well, I cleaned and greased everything and put those needles back in without the retainer stuff and rode on that bearing for 200,000 miles with no ill effects.

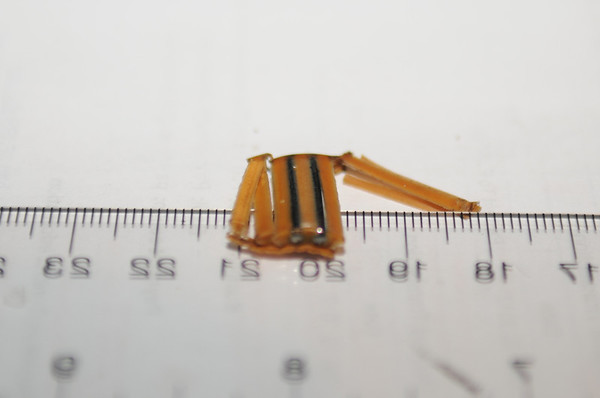

That being said, now that I know better I try to keep that retainer gunk in place when I can and try to clean the bearing gently. That doesn't always work. As the photos below show, sometimes some the retainer stuff goes partially MIA. No bid deal. I don't lose any sleep over it. Just grease it well and ride more, stress less. And the photos aren't perfect, but I think you can see that needles are pretty well packed and aren't going to 'migrate' anywhere even without the retaining stuff.

One last thing - My first FJR went 226,000 miles without ever replacing any of these bearings or collars. Preventative maintenance is the key to keeping them happy an having an indefinite life.

So here's my $.02.

I don't think it matters either way.

Way back in 2004 when installing my Wilbers shock on my first 04 FJR I came across this stuff and thought it was congealed grease. As I was removing it, I realized it was supposed to be there. Well, I cleaned and greased everything and put those needles back in without the retainer stuff and rode on that bearing for 200,000 miles with no ill effects.

That being said, now that I know better I try to keep that retainer gunk in place when I can and try to clean the bearing gently. That doesn't always work. As the photos below show, sometimes some the retainer stuff goes partially MIA. No bid deal. I don't lose any sleep over it. Just grease it well and ride more, stress less. And the photos aren't perfect, but I think you can see that needles are pretty well packed and aren't going to 'migrate' anywhere even without the retaining stuff.

One last thing - My first FJR went 226,000 miles without ever replacing any of these bearings or collars. Preventative maintenance is the key to keeping them happy an having an indefinite life.