Fontanaman

Robin Trower

Sounds like they could use a little design modification. Here we are thinking that we were making mistakes on the install and it is at least partly due to their inadequate design.

Yeah, you can ignore minor stuff like this and other routine maintenance stuff and get away with it for a long time. But when it bites you in the *** when you're on the road in east BFE, it can be a major PITA. You buy your ticket and you take your chances.

Only a little Fred?

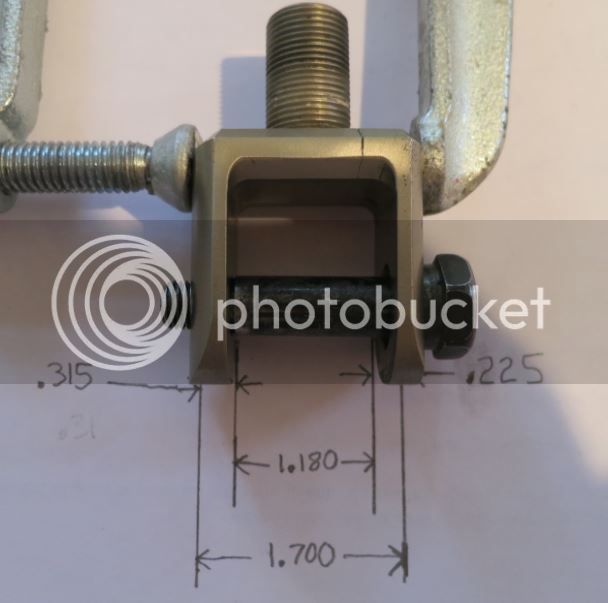

A 650 lbs motorcycle with an aluminum rear shock clevis where one side of the clevis only has 41% engagement with the minor diameter of the bolt.

Last edited by a moderator: