lnewlf

Well-known member

so basically the collar might be to short for the Penske clevis....easy phix as above..

new Penske coming

new Penske coming

+1FWIW, the Penske clevis on my Tenere is exactly the same design (other than hole diameter) as the FJR. I don't recall any discussion regarding failures on the Tenere forums.With a minor modification to the FJR stock shoulder bolt or a thin shim, the potential clevis issue is eliminated. Not a deal breaker for me but as always...

YMMV

--G

Like HelzBelz I sent an email to Eric at about the same time. I haven't heard squat back and this from a company that said this was a high priority.Just a small update as the Snow is stopping here in Bozeman soon, I hope.

I followed up with Eric at Penske to see if anything can be said to those of us without failures, but with concerns. Email was sent on 2/18. No reply yet.

I may call today, but I guess I don't know what to expect. I am going to move forward with the shaving the bolt head idea, might buy a new bolt to work on that.

My current bolt has been fastened since June 2016, and I know I had the slight gap before Torquing her down. (gap gone after that...)

I will likely video my loosening of that bolt, to see if the gap re-appears, just for ***** and giggles.

Otherwise, I am dying to ride. (and to move to warmer climate as soon as the kideos are off to college (once is gone in two years, the other 4)

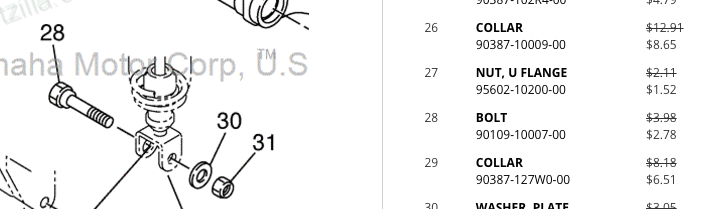

I am assuming that this is the yamaha bolt part number that needs a little machine work done to it correct?Like HelzBelz I sent an email to Eric at about the same time. I haven't heard squat back and this from a company that said this was a high priority.Just a small update as the Snow is stopping here in Bozeman soon, I hope.

I followed up with Eric at Penske to see if anything can be said to those of us without failures, but with concerns. Email was sent on 2/18. No reply yet.

I may call today, but I guess I don't know what to expect. I am going to move forward with the shaving the bolt head idea, might buy a new bolt to work on that.

My current bolt has been fastened since June 2016, and I know I had the slight gap before Torquing her down. (gap gone after that...)

I will likely video my loosening of that bolt, to see if the gap re-appears, just for ***** and giggles.

Otherwise, I am dying to ride. (and to move to warmer climate as soon as the kideos are off to college (once is gone in two years, the other 4)

And I too will be getting my bolt machined down to rid myself if thispeskyPenske problem.

Agree...My Wilbers 641 should arrive on Tuesday along with the big storm...at less than $800 shipped it was cheaper than Penske too.. remote compression and rebound, no remote preloadI was pricing the Penske 8983 with a Dealer/Installer, who claimed no knowledge of this recent clevis breakage issue. So, I visited the Penske website, and of course there is no update. Could it be that Penske is quietly letting this clevis design stand, unimproved ? I am not buying a damper with this clevis design.

Enter your email address to join: