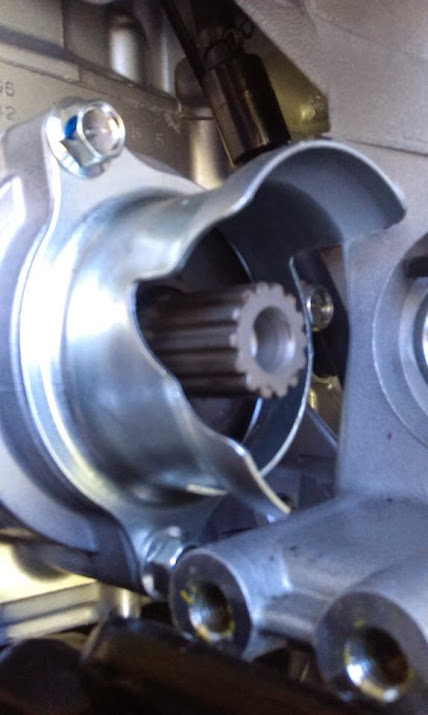

Yes there is some oxidation on the splines too. Good? Not sure based on some of the responses, but I don't think it is good.Was I the only one to see corrosion on the spline? Somebody please tell me that is a good thing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drivetrain lack of lubrication

- Thread starter Allen_C

- Start date

Help Support Yamaha FJR Motorcycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

HotRodZilla

GOD BLESS AMERICA

Bust is just hurt cuz he hates it when his rear end isn't lubed.Wow, some varied responses. As Bust noted, I am aware of the issue, no it's not that bad, I haven't heard of any other Gen 3 owner indicate what they found when opening up the pumpkin - hence my question to other owners.

In any case, I feel it is a shame that Yamaha still seems to be inconsistent in lubricating these parts.

Carry on...

FJRMGM

FJRMGM

- Joined

- Jun 14, 2005

- Messages

- 2,098

- Reaction score

- 45

Too many subscribe to the "if a little grease is good then a lot must be much better" theory.

SoCalFJR1300

Well-known member

So why does this site tell people to check it and lube??Rust formed on the drive shaft itself makes absolutely no difference in the world. It's a solid steel shaft for crying out loud. It's not going to weaken and break. Ever look at the drive shaft on the underside of a car? At least the FJR shaft runs inside a housing to protect it from road spray (and your leg, no doubt)

The splines on the forward end of the shaft require only a light coat of greasing upon assembly, strictly for anti-corrosion. There is no lateral motion or friction in that spline joint during use. All of that lateral motion is taken up in the spring loaded rear joint, which is inside the final drive and lubed in gear oil.

The splines that couple to the rear wheel hub already had plenty of grease on them in your original picture. Again, this grease is merely anti-corrosive. There is no motion of that spline coupling either (other than rotational) You do not want to globber a lot grease on that joint or it will migrate out and onto your rear wheel via centripetal force.

Neither of these locations require anything as fancy as Honda Moly Paste lube, as is often recommended, but it does have the unique advantage of sticking rather tenaciously to surfaces (and your fingers) when applied in a thin layer. So, I would say that you could do that if it makes you feel better (keep the grease coating thin!) but certainly not to worry the least bit about the shaft being a little corroded.

If you were to complain to Yamaha corporation about their heinous oversight, they'd tell you that you are just another internet kook making up problems. The FJR has among the most reliable final drives in the industry. And the vast majority of owners never apply grease on either of these parts since it is not called for in the Factory Service Manuals.

From the "06-012 BIn O Facts"

"Things to check at 600 Miles":

"Drive shaft spline, most have insufficient moly"

Last edited by a moderator:

HotRodZilla

GOD BLESS AMERICA

1st: Don't be mean to SoCalFJR1300 like that. He just got rid of all his negatives.Oh Nice!! Hijack a legit thread.No wonder everyone hates you ya fuker.

2nd: I am also of the mind that too much lube does no real good. If a little oxidation on the driveshaft is concerning, use some steel wool and clean it off. Then put a very light coat on it to protect it. However, as said before, if left to rust, we'll have to replace them in about 300 years. I'm not sure about that forward gear, but I lubed mine, I couldn't help it. I like my rear end lubed too it seems.

Last edited by a moderator:

SoCalFJR1300

Well-known member

Ummm....I think that comment was made towards you Zilla.1st: Don't be mean to SoCalFJR1300 like that. He just got rid of all his negatives.Oh Nice!! Hijack a legit thread.

No wonder everyone hates you ya fuker.

I certainly was on topic with the lube question??

$22.09

$25.99

MOREOK Waterproof & Windproof -30°F Winter Gloves for Men/Women, 3M Thinsulate Thermal Gloves Touch Screen Warm Gloves for Skiing,Cycling,Motorcycle,Running-Black-L

MOREOK-US (Ships from USA)

$49.99

$54.99

HOOD CREW Men’s Casual Stand Collar PU Faux Leather Zip-Up Motorcycle Bomber Jacket With a Removable Hood

Jamickiki

$24.37

Fuel Tank Sticker Motorcycle Stickers for Yam&aha FJR1300 FJR 1300 Tank Pad Protector Decal Emblem Side Fairing Symbol Adventure

nanyangshixianpushangmaohanggerenduzi

$64.99

Edwards Oil Change Kit fits 2003-2020 Yamaha FJR1300 Sport Touring

Edwards Motorsports & RV's

$127.99

$159.99

FLAVOR Men Brown Leather Motorcycle Jacket with Removable Hood (Large (US standard), Brown)

FLAVOR Leather

$15.15

$21.95

Tough Headwear Balaclava Ski Mask - Winter Face Mask for Men & Women - Cold Weather Gear for Skiing, Snowboarding & Motorcycle Riding (Black)

Tough Outfitters

$44.99

Real Time Industries Reflective Decals for Yamaha FJR1300 Gen 2 Fairing (Black - Silver Print)

Real Time Industries

$22.09

$25.99

MOREOK Waterproof & Windproof -30°F Winter Gloves for Men/Women, 3M Thinsulate Thermal Gloves Touch Screen Warm Gloves for Skiing,Cycling,Motorcycle,Running-Black-XL

MOREOK-US (Ships from USA)

So why does this site tell people to check it and lube??Rust formed on the drive shaft itself makes absolutely no difference in the world. It's a solid steel shaft for crying out loud. It's not going to weaken and break. Ever look at the drive shaft on the underside of a car? At least the FJR shaft runs inside a housing to protect it from road spray (and your leg, no doubt)

The splines on the forward end of the shaft require only a light coat of greasing upon assembly, strictly for anti-corrosion. There is no lateral motion or friction in that spline joint during use. All of that lateral motion is taken up in the spring loaded rear joint, which is inside the final drive and lubed in gear oil.

The splines that couple to the rear wheel hub already had plenty of grease on them in your original picture. Again, this grease is merely anti-corrosive. There is no motion of that spline coupling either (other than rotational) You do not want to globber a lot grease on that joint or it will migrate out and onto your rear wheel via centripetal force.

Neither of these locations require anything as fancy as Honda Moly Paste lube, as is often recommended, but it does have the unique advantage of sticking rather tenaciously to surfaces (and your fingers) when applied in a thin layer. So, I would say that you could do that if it makes you feel better (keep the grease coating thin!) but certainly not to worry the least bit about the shaft being a little corroded.

If you were to complain to Yamaha corporation about their heinous oversight, they'd tell you that you are just another internet kook making up problems. The FJR has among the most reliable final drives in the industry. And the vast majority of owners never apply grease on either of these parts since it is not called for in the Factory Service Manuals.

From the "06-012 BIn O Facts"

"Things to check at 600 Miles":

"Drive shaft spline, most have insufficient moly"

Since your question was directed to me, I'll answer:

Early on in the FJR model's history, owners found quite a few shortcomings in the Yamaha technical literature. Things like the drain plug torque recommendation being far too high, and the "requirements" to rebuild the clutch and brake master cylinders every two years, and replace the hydraulic brake hoses every 4 years. There are many more such "pearls" in the FSM if you dig deeply. The point is, the early adopters began to question the veracity of the official Yamaha documents.

They reasoned further, if the engineers and tech-writers had included such whacked out recommendations in their service requirements, what might they have omitted? People began recreational disassembly of their bikes looking for problems, real or imagined. These dry (ungreased) splines at the forward end of the drive shaft and some light corrosion was found to exist on almost all new bikes, and an assumption was made that these splines functioned in the same way as the BMW drive shaft splines, which are a well known failure point on those bikes if not properly maintained.

The difference is that those BMW splines are the slip joint for the entire drive shaft. They allows the shaft to slide laterally, to allow the shaft to vary in length when the suspension articulates. Which, when done under load, will cause rapid wear of the spline joint if not well greased resulting in spline failure. This is not true in the Yamaha driveline. In the FJR those splines are only a means of assembling that joint, after which there will be no lateral motion. As I described previously, that slip joint is at the rear end of the FJR drive shaft, bathed in gear lube, which explains why, unlike on BMWs, you never hear about drive shaft splines failing on an FJR.

But, like most internet legend, once a "fact" has been repeated often enough, it becomes unquestionably true. I suggest that you do not blindly take my (or anyone else's) word for it. Look at how these parts function and think about that yourself, then go with what seems right to you.

Last edited by a moderator:

snackbauer

Well-known member

The FSM does instruct to apply LS to the forward splines on reassembly, you'd think the factory would have done it at initial assembly. I'm guilty of over lubing the forward spline, had some lube sling off making me suspect a problem with a seal. Fortunately I didn't tear into that. I'll check and lightly lube in the future, maybe at about 50k miles, which may be never if my seat doesn't get back soon.

SoCalFJR1300

Well-known member

Thanks Fred.Since your question was directed to me, I'll answer:So why does this site tell people to check it and lube??Rust formed on the drive shaft itself makes absolutely no difference in the world. It's a solid steel shaft for crying out loud. It's not going to weaken and break. Ever look at the drive shaft on the underside of a car? At least the FJR shaft runs inside a housing to protect it from road spray (and your leg, no doubt)

The splines on the forward end of the shaft require only a light coat of greasing upon assembly, strictly for anti-corrosion. There is no lateral motion or friction in that spline joint during use. All of that lateral motion is taken up in the spring loaded rear joint, which is inside the final drive and lubed in gear oil.

The splines that couple to the rear wheel hub already had plenty of grease on them in your original picture. Again, this grease is merely anti-corrosive. There is no motion of that spline coupling either (other than rotational) You do not want to globber a lot grease on that joint or it will migrate out and onto your rear wheel via centripetal force.

Neither of these locations require anything as fancy as Honda Moly Paste lube, as is often recommended, but it does have the unique advantage of sticking rather tenaciously to surfaces (and your fingers) when applied in a thin layer. So, I would say that you could do that if it makes you feel better (keep the grease coating thin!) but certainly not to worry the least bit about the shaft being a little corroded.

If you were to complain to Yamaha corporation about their heinous oversight, they'd tell you that you are just another internet kook making up problems. The FJR has among the most reliable final drives in the industry. And the vast majority of owners never apply grease on either of these parts since it is not called for in the Factory Service Manuals.

From the "06-012 BIn O Facts"

"Things to check at 600 Miles":

"Drive shaft spline, most have insufficient moly"

Early on in the FJR model's history, owners found quite a few shortcomings in the Yamaha technical literature. Things like the drain plug torque recommendation being far too high, and the "requirements" to rebuild the clutch and brake master cylinders every two years, and replace the hydraulic brake hoses every 4 years. There are many more such "pearls" in the FSM if you dig deeply. The point is, the early adopters began to question the veracity of the official Yamaha documents.

They reasoned further, if the engineers and tech-writers had included such whacked out recommendations in their service requirements, what might they have omitted? People began recreational disassembly of their bikes looking for problems, real or imagined. These dry (ungreased) splines at the forward end of the drive shaft and some light corrosion was found to exist on almost all new bikes, and an assumption was made that these splines functioned in the same way as the BMW drive shaft splines, which are a well known failure point on those bikes if not properly maintained.

The difference is that those BMW splines are the slip joint for the entire drive shaft. They allows the shaft to slide laterally, to allow the shaft to vary in length when the suspension articulates. Which, when done under load, will cause rapid wear of the spline joint if not well greased resulting in spline failure. This is not true in the Yamaha driveline. In the FJR those splines are only a means of assembling that joint, after which there will be no lateral motion. As I described previously, that slip joint is at the rear end of the FJR drive shaft, bathed in gear lube, which explains why, unlike on BMWs, you never hear about drive shaft splines failing on an FJR.

But, like most internet legend, once a "fact" has been repeated often enough, it becomes unquestionably true. I suggest that you do not blindly take my (or anyone else's) word for it. Look at how these parts function and think about that yourself, then go with what seems right to you.

public ADVISORY (because whacking the pee pee of everyone is time consuming):

Drop the PITA post structures. (long ... between words).

Threadjacking will get WARNS though (for each).

Drop the PITA post structures. (long ... between words).

Threadjacking will get WARNS though (for each).

AND Honda - which also has a long history of IGNORED splines failing over time.and an assumption was made that these splines functioned in the same way as the BMW drive shaft splines

Queensland Ken

Well-known member

As others have mentioned, it's not do much the cosmetic surface rust but a lack of lubrication within the splines.I haven't heard of any other Gen 3 owner indicate what they found when opening up the pumpkin.

You should have went further and checked the universal.

A 2014 with 1100kms

Also recently did a mates 2010 with 50K kms, the drive was rusted into the universal and eventually removed it and the universal from the middle gear.

Last edited by a moderator:

RaYzerman19

Go Wings!

If you understand the basic principle that all splines have clearances that allow them to be assembled, will allow them to move longtitudinally and radially..... and the basic principle that metal on metal movement generates heat and wear......... and that corrosion will prevent such movement where movement was intended, thus potentially stressing the adjacent component (U-joint)......... why the heck would you not lube splines at least once, to satisfy yourself that it was done right at least once, and that if you used a good quality stuff, it might last a long time before you have to do it again........

Who among us is willing to wash away the existing if any, lube and run them dry... I'd like your report on how long they last please....... yup, I don't think I'm about to get many volunteers...........

Who among us is willing to wash away the existing if any, lube and run them dry... I'd like your report on how long they last please....... yup, I don't think I'm about to get many volunteers...........

SoCalFJR1300

Well-known member

Bottom line...IMOP, metal to metal parts that move together should have lube.

GalaxyBlue

Well-known member

Cleaning up the thread... Please stay on topic. Thank you.

HotRodZilla

GOD BLESS AMERICA

Gotta agree with that one. That's why I did mine a couple years ago. There were already stories if guys having grease flung all over that forward plastic cover, so I went light and haven't seen any signs of wear, corrosion or seizing.Bottom line...IMOP, metal to metal parts that move together should have lube.

If you understand the basic principle that all splines have clearances that allow them to be assembled, will allow them to move longtitudinally and radially..... and the basic principle that metal on metal movement generates heat and wear......... and that corrosion will prevent such movement where movement was intended, thus potentially stressing the adjacent component (U-joint)......... why the heck would you not lube splines at least once, to satisfy yourself that it was done right at least once, and that if you used a good quality stuff, it might last a long time before you have to do it again........

Yes I understand the basic principle of a spline joint. Yes they have clearances to allow them to be assembled. Be pretty tough to do that otherwise. Yes they can move longitudinally, but this one does not move laterally in use because it is forced all the way forward by the spring pressure from the back end of the drive shaft. With no movement there is no heat build up or wear. There is no need for lubrication of this joint to prevent wear.

What there is a need for is corrosion protection. Your last few clauses are exactly my point. Smear some kind of sticky, ideally waterproof grease on the joint during assembly, like it says to in the manual. If you have a new (to you) bike, doing it at the first tire change of ownership is probably a great idea.

Nobody here is advocating washing the joint clean and running it without any corrosion protection. That isn't what it says to do in the manual either. Why they seem to come from the factory completely dry is a mystery, considering it says to grease that joint during assembly. But after you've done it once you can pretty much stand-down and find something else to obsess over, IMO.

YMMV

All lubes dry over time. PM on it is also a good idea. What better time to do it than when PMing the driven splines in the hub? Without SOME kind of routine, it's easy to completely forget.

Pterodactyl

Well-known member

Should I be worried that the drive shaft on my Toyota pick-up truck is completely rusted and the splines have never been lubed. I hear rumor after rumor that people are only getting 200-250 miles on these things.

RaYzerman19

Go Wings!

Yes, lube your Toyota splines. There may be a Zerk fitting or a hole for a needle type greaser. The U-joint on the FJR is able to float back and forth with swingarm travel, although it isn't very much. This keeps the stress off the U-joint. For full jounce, the spring loaded part at the rear drive will compress if the U-joint is pushed forward "against the stop" so to speak. Automotive driveshafts travel way more with suspension travel and the spline must be able to slide the majority of its range. I have seen many locked up by rust and will make some funky clunks and other funny noises as it sticks and unsticks when rusty..... and you're not doing the U-joint any favours by allowing that kind of stress on it. No need to "obsessive" or be overzealous on the grease, a coating is good enough as the clearances are small in the splines. Your first application of grease will last a very long time.....

Last edited by a moderator:

Similar threads

- Replies

- 0

- Views

- 668

Motorcycle For Sale

(Pending Sale) 2009 Yamaha FJR1300 AE Automatic w/ 7k Miles ! Mint

- Replies

- 15

- Views

- 2K

- Replies

- 2

- Views

- 914

Motorcycle For Sale

SOLD - 2007 Yamaha FJR1300 - $2500 - Colchester, Connecticut

- Replies

- 2

- Views

- 925