You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil Change Debacle with Drain Plug?

- Thread starter woodcycl

- Start date

Help Support Yamaha FJR Motorcycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

escapefjrtist

Searching for Dry Roads

Yup, practice this at every oil change, step away from the torque wrench!oh, and snug is good.. just Snug.

--G

Donal

Well-known member

If you feel like you have to use a torque wrench then something like 20 ft.lbs is good.........Yup, practice this at every oil change, step away from the torque wrench!oh, and snug is good.. just Snug.

--G

mcatrophy

Privileged to ride a 2018 FJR1300AS

Also remember that the thread after draining the oil will be well lubricated.

Maybe (just maybe) 31 ft-lb is ok for a dry thread, which is probably what is done in the factory. (And how many complaints have we seen here about being unable to remove that plug for the first oil change?)

In the factory is the only time that thread will be dry in the life of the bike. (No, a wipe with a rag on your pinky up the drain hole will not dry the thread

.)

.)

Maybe (just maybe) 31 ft-lb is ok for a dry thread, which is probably what is done in the factory. (And how many complaints have we seen here about being unable to remove that plug for the first oil change?)

In the factory is the only time that thread will be dry in the life of the bike. (No, a wipe with a rag on your pinky up the drain hole will not dry the thread

Honestly, I think 31 lb-ft is too much even for the dry threads of that size (thickness) in soft alloy. I recall a bunch of people having the threads come out with the drain plug the very first time it was removed. That's a good reason for opting to have the stealership do the 600 mile oil change, so if it happens the new oil pan will be on their dime.

As for the repair choices, the self tapping oversized plugs will be the cheapest, easiest to install, but also least likely to be successful. Which would not be a big deal as long as the self-tapping over-sized threads don't ream the hole out to be too big for one of the other solutions.

The best solution, short of replacing the oil pan, is the Time-Sert. The repair will be better than new (you'll have new harder threads in the insert, but it is nearly the cost of replacing the pan.

The helicoil is your middle option. When installed the coil will be the new threads, but it is a coil and so the threads are not as solid as the Time-Sert.

FWIW - The timesert hole size is smaller than the helicoil hole after retapping, so if you choose a helicoil and it doesn't work out, I don't think you'll be able to go with a Time-Sert

As for the repair choices, the self tapping oversized plugs will be the cheapest, easiest to install, but also least likely to be successful. Which would not be a big deal as long as the self-tapping over-sized threads don't ream the hole out to be too big for one of the other solutions.

The best solution, short of replacing the oil pan, is the Time-Sert. The repair will be better than new (you'll have new harder threads in the insert, but it is nearly the cost of replacing the pan.

The helicoil is your middle option. When installed the coil will be the new threads, but it is a coil and so the threads are not as solid as the Time-Sert.

FWIW - The timesert hole size is smaller than the helicoil hole after retapping, so if you choose a helicoil and it doesn't work out, I don't think you'll be able to go with a Time-Sert

ahchiu

FJR Commander

I torque mine the same as the rear diff, that only calls for 17 # and it's the same bolt.

$159.99

FLAVOR Men Brown Leather Motorcycle Jacket with Removable Hood (Large (US standard), Brown)

FLAVOR Leather

$197.39

$209.99

Milwaukee Leather SH1408 Men's Sporty Crossover Vented Black Motorcycle Leather Scooter Jacket - Large

Amazon.com

$79.95

Harley-Davidson Water-Resistant Travel Hybrid Duffel Bag/Backpack - Black

Wisconsin Harley-Davidson

$24.37

Fuel Tank Sticker Motorcycle Stickers for Yam&aha FJR1300 FJR 1300 Tank Pad Protector Decal Emblem Side Fairing Symbol Adventure

nanyangshixianpushangmaohanggerenduzi

$64.99

Edwards Oil Change Kit fits 2003-2020 Yamaha FJR1300 Sport Touring

Edwards Motorsports & RV's

$98.16

25-1775 Replacement for All Balls Wheel Bearing Kit (25-1775) for Yamaha FJR1300 03-16 FJR1300ES 14-18

Otisdelilah Auction

$89.45

No Cutting Motorcycle Frame Slider Anti-collision Drop For Yamaha FJR1300 FJR 1300 2006-2011 motorcycle crash pad(Carbon Fiber Look)

dengzhoushijiushuncaishangmaoyouxiangongsi

$91.99

Edwards Maintenance Kit fits 2003-2020 Yamaha FJR1300 Sport Touring

Edwards Motorsports & RV's

Pterodactyl

Well-known member

On the OEM Yamaha site a new oil pan for a 2009 is $345. There is a used one for a GENI on ebay for $135. A gasket is going to cost $28. Just a quick check to give a range of prices.

SouthernCruizer

Is it Beer:30 yet?

looks like he got his answer by the many posts here. I'll just throw this out there for any new FJR owner reading this...after having wrenched on all 3 gens of FJRs, I've come to the conclusion, thru trial and error and other owners reports, that the ONLY thing a torque wrench should be used for on the FJR are the motor mount bolts. Other than those, best to keep the torque wrench in the tool chest and just go by feel.

just my $.02 worth. Void where prohibited.

just my $.02 worth. Void where prohibited.

mcatrophy

Privileged to ride a 2018 FJR1300AS

Couldn't agree more, except I don't even use one for the bolts that hold the sliders to the engine mounts. Never had a problem with them (installed when new over three years and 28500 miles ago, checked once after about six months).looks like he got his answer by the many posts here. I'll just throw this out there for any new FJR owner reading this...after having wrenched on all 3 gens of FJRs, I've come to the conclusion, thru trial and error and other owners reports, that the ONLY thing a torque wrench should be used for on the FJR are the motor mount bolts. Other than those, best to keep the torque wrench in the tool chest and just go by feel.

just my $.02 worth. Void where prohibited.

I would only use one on stretch bolts, such as head bolts, but I hope I never need to

bluesdog

Well-known member

Both the FSM and the forum’s ‘Bin O Facts’ specify 31 lb-ft torque for the oil drain plug.

From the BOF:

I think Yamaha should have issued a service bulletin describing the correct way to tighten the drain bolt. Which is to say, no torque wrench needed — just tighten until the crush washer flattens, (you can feel it!), or reduce the torque to something more reasonable, say 17 - 22 lb-ft. On one of my last oil changes, as a test I used a torque wrench, starting at @ 15 lb-ft and setting it progressively higher until I felt the crush washer flatten at @ 20 lb-ft, iirc

I’ve wrenched on a lot of bikes over the years, and only recently acquired a torque wrench, specifically for things such as wheel bolts, engine mount bolts and so on.

From the BOF:

Note that the BOF does mention the following, but fails to offer instruction for proper procedure:31. M14 Oil drain bolt (same as prior models) ** See notes in 'Servicing' section of this post.

Our BOF is sadly in need of an update, BTW, and perhaps some of the misleading information could be corrected along with the update. Maybe a group effort?Several have posted issues with the 31 ft-lb Yamaha specified oil drain bolt torque (i.e. 'stripping' the threads). Also several posts on factory believed to have over tightened the oil drain bolt.

I think Yamaha should have issued a service bulletin describing the correct way to tighten the drain bolt. Which is to say, no torque wrench needed — just tighten until the crush washer flattens, (you can feel it!), or reduce the torque to something more reasonable, say 17 - 22 lb-ft. On one of my last oil changes, as a test I used a torque wrench, starting at @ 15 lb-ft and setting it progressively higher until I felt the crush washer flatten at @ 20 lb-ft, iirc

I’ve wrenched on a lot of bikes over the years, and only recently acquired a torque wrench, specifically for things such as wheel bolts, engine mount bolts and so on.

The owners of those three different areas (one is already updated) may not catch this one post with all the threads on the forum. Perhaps you can send them a PM or add a post in the particular BOF section.Our BOF is sadly in need of an update, BTW, and perhaps some of the misleading information could be corrected along with the update. Maybe a group effort?

Last edited by a moderator:

A bunch of folks are under the false impression that a torque wrench is a tool that can only be safely used on massively tightened, large torque fasteners. The truth is that a torque wrench is used quite often in industrial assembly situations where the fasteners are small and/or delicate (think specs in inch pounds) and the reason to use them is to prevent causing damage from over torquing as well as fasteners coming loose due to under torquing. Granted, that requires that the torque specs be correct for that fastener and the torque wrench to also be reasonably accurate.

The problem here isn't from using a torque wrench. It's from using the faulty spec that Yamaha has published. There also may be some variability in our torque wrenches' accuracy, but in this drain plug example, it is just a bad spec.

The problem here isn't from using a torque wrench. It's from using the faulty spec that Yamaha has published. There also may be some variability in our torque wrenches' accuracy, but in this drain plug example, it is just a bad spec.

Last edited by a moderator:

Pterodactyl

Well-known member

BMW published a similar bad torque for the cylinder head retaining nuts on some of their old bikes. Caused many a stud to pull loose from the engine block at great expense to the owner.

dcarver

Well-known member

Fred, with your scientific approach background, you'll find this amusing, or distressing... All fasteners EXCEPT some true 'critical' ones, get cleaned of all dirt, debris, grease, oil. Then they get a slathering of anti-seize prior to assembly. Final torque is the dcarver time proven 25% less than spec (clean, lubed threads vs dry) then I torque by hand. To exactly +/- 0.2 nanoseconds. (oh, wait, wrong units?)

Some exceptions, of course. Head bolts come to mind. But axles, pinch bolts, sub-frame, gas tank, and, yes, oil pan bolt. It's really well lubricated to start with.

Once again, no science... but years ago I serendipitously discovered that all bolts, studs and nuts that were slathered in grease never fell off on the big single cylinder TT-500 Yamaha paint shaker. The other ones did.. Perhaps the thread void being filled helps? Not sure, and guess it doesn't matter.

At the nuke plant we don't rely on torque indicating devices but stud stretch as measured by +/- 0.0001" dial indicators. That's a bit much for an FJR.

Then I discovered anti-seize and game ON!

Ok, maybe a bit over the top - but none of the fasteners on kRzY8 are stripped. Not one. And as you know, she's had many an evolution..

Some exceptions, of course. Head bolts come to mind. But axles, pinch bolts, sub-frame, gas tank, and, yes, oil pan bolt. It's really well lubricated to start with.

Once again, no science... but years ago I serendipitously discovered that all bolts, studs and nuts that were slathered in grease never fell off on the big single cylinder TT-500 Yamaha paint shaker. The other ones did.. Perhaps the thread void being filled helps? Not sure, and guess it doesn't matter.

At the nuke plant we don't rely on torque indicating devices but stud stretch as measured by +/- 0.0001" dial indicators. That's a bit much for an FJR.

Then I discovered anti-seize and game ON!

Ok, maybe a bit over the top - but none of the fasteners on kRzY8 are stripped. Not one. And as you know, she's had many an evolution..

Last edited by a moderator:

mcatrophy

Privileged to ride a 2018 FJR1300AS

This is 100% my thinking.Fred, with your scientific approach background, you'll find this amusing, or distressing... All fasteners EXCEPT some true 'critical' ones, get cleaned of all dirt, debris, grease, oil. Then they get a slathering of anti-seize prior to assembly. Final torque is the dcarver time proven 25% less than spec (clean, lubed threads vs dry) then I torque by hand. To exactly +/- 0.2 nanoseconds. (oh, wait, wrong units?)

Some exceptions, of course. Head bolts come to mind. But axles, pinch bolts, sub-frame, gas tank, and, yes, oil pan bolt. It's really well lubricated to start with.

Once again, no science... but years ago I serendipitously discovered that all bolts, studs and nuts that were slathered in grease never fell off on the big single cylinder TT-500 Yamaha paint shaker. The other ones did.. Perhaps the thread void being filled helps? Not sure, and guess it doesn't matter.

At the nuke plant we don't rely on torque indicating devices but stud stretch as measured by +/- 0.0001" dial indicators. That's a bit much for an FJR.

Then I discovered anti-seize and game ON!

Ok, maybe a bit over the top - but none of the fasteners on kRzY8 are stripped. Not one. And as you know, she's had many an evolution..

In my case, when I was very much younger, I spent a great deal of time keeping my Tiger Cub running. Many of the bolts on that were into soft aluminium. I very soon learnt to use something to prevent seizure, usually grease, or next time the bolt would come out with aluminium embedded in the thread. Also how tight; too loose and the bolt would shake out within a few miles, too tight and the aluminium-in-the-bolt's-thread effect would be immediate

Later I did all servicing on a number of cars, from oil changing to putting whole new bodies on wrecks. Never a problem (except where I'd forgotten to tighten something

I now use feel on all normal bolts and suchlike, and haven't had a problem with any modern car or bike. I generally use copper grease as an anti-seize.

I don't own a torque wrench, but I would get one if I was going to do cylinder head or similar "stretch" bolts.

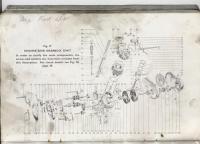

This is what my Cub looked like for a lot of its time:

(Click on image for larger view)

Taken from the Instruction Manual that came with the bike, equivalent to a workshop manual so the owner can do any task. And not a single mention of torque values. Not even for the engine (not that it ever gave very much

I don't think that I would rely on anti-seize to help keep a bolt or nut secure, but if it's workin' for you... keep doin' what works.

FWIW, I do not torque every fastener using a wrench like some folks do. I do use a torque wrench for the more "critical" items, but a drain plug with a crush washer I do not consider to be one of those. And you may recall that a while ago I posted a way to check the accuracy of your torque wrenches without paying a metrology lab to calibrate it.

After a while you also get a 6th sense for torque. We have an application at work that uses some fine brass screws threaded into small metal plates that are then subjected to a lot of magnetism. If they come loose it causes big problems. But more importantly if you over torque those little screws it is very easy to strip one and the metal plate will still come loose. The torque spec for those screws is 10 inch pounds with a screwdriver type torque wrench. It's amazing how accurately you can guess 10 inch pounds after you've done up a thousand of those screws in the course of a couple of days.

FWIW, I do not torque every fastener using a wrench like some folks do. I do use a torque wrench for the more "critical" items, but a drain plug with a crush washer I do not consider to be one of those. And you may recall that a while ago I posted a way to check the accuracy of your torque wrenches without paying a metrology lab to calibrate it.

After a while you also get a 6th sense for torque. We have an application at work that uses some fine brass screws threaded into small metal plates that are then subjected to a lot of magnetism. If they come loose it causes big problems. But more importantly if you over torque those little screws it is very easy to strip one and the metal plate will still come loose. The torque spec for those screws is 10 inch pounds with a screwdriver type torque wrench. It's amazing how accurately you can guess 10 inch pounds after you've done up a thousand of those screws in the course of a couple of days.

Same crush washer too. If 17 lb-ft is enough for that one it should be good enough for the drain pan too.I torque mine the same as the rear diff, that only calls for 17 # and it's the same bolt.

08FJR4ME

-WYNPRO-

The only thing I ever torque on my Feejer are the axle nuts. everything else is by feel.

Dave

Dave

extrememarine

Well-known member

There is a note in the Gen II bin-o-facts regarding the issue of over tightening of the drain plug if the 31ft/lb spec is used - it's under "No-Hassle FJR1300 Oil Change" notes. What portion of the bin'0'facts post did you look at and pull this spec from? I'll add a note there in hopes of helping in the future.

Then it would be a really good idea to update the '06 - '12 Bin O Facts (Generation II) thread ... as even though I have the full maintenance manual, I do follow these threads pretty closely and used 31 as the magic number thinking I was being good at my torque settings! Ugh!The drain bolt isn't your problem here. You stripped the threads right out of your oil pan. You now have two options, repair or replace the oil pan. The torque spec in the manual for that plug is ludicrous...way too high. It's been very well documented on this forum.

Sharif

Well-known member

I use the old German axiom when snugging up my drain bolt (after stripping the thing on my last bike) - "Gudntight." No torque wrench.

Geezer

Parsimonious Curmudgeon

I own a couple of torque wrenches and use them on engine internals when I am working on an engine, but I have never used one on my FJR. I replaced the crush washers on my oil drain plug with a copper washer and it has never stripped the threads nor leaked any oil. I put the same type of copper washer on both differential plugs.

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 3

- Views

- 2K