TownsendsFJR1300

Well-known member

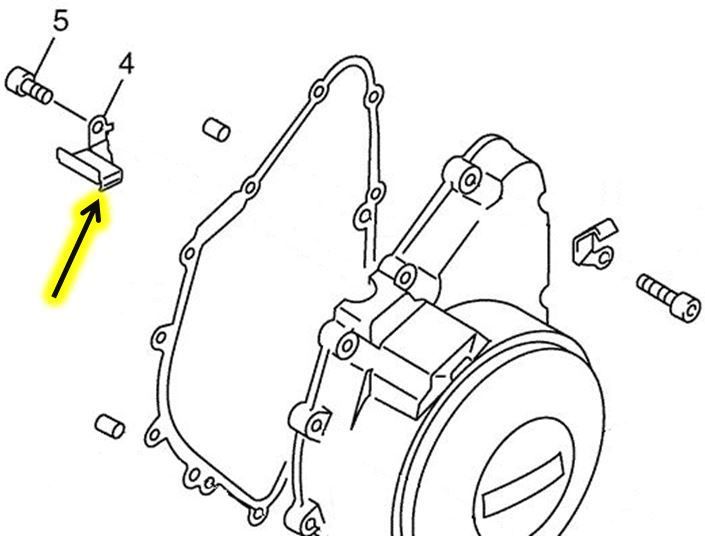

I've replaced my cover (FZ6-same set up, same issues) twice.

Its a super loctite used .

A heat gun set medium to high at the aluminum cover itself (around the bolt) for 15 seconds or

so will make the loctite loosen and it'll come out fairly easily.

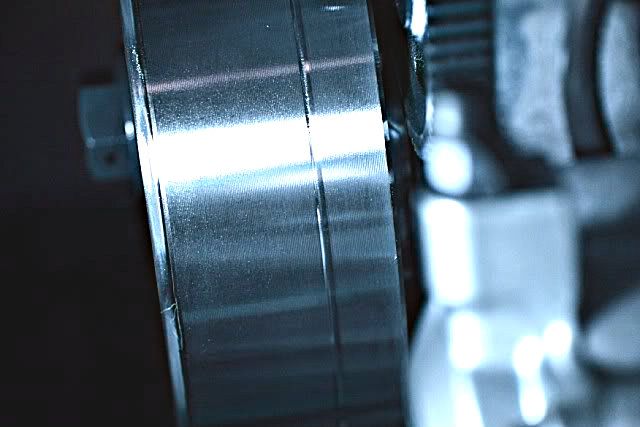

The stator bolts were the same, had to add heat and they came out without a problem,.

I re-used all the original bolts as they weren't damaged.

Too late now, but I didn't even un-plug the stator cover from the wiring harness.

I put a short, STRONG stool next to the bike, popped the cover off and set it

on the stool and worked right there. Saved lifting the tank, finding the harness, etc,

piece of cake..

For the new cover, just put a clean, doubled over towel on the stool to the new cover

looking new...

Its a super loctite used .

A heat gun set medium to high at the aluminum cover itself (around the bolt) for 15 seconds or

so will make the loctite loosen and it'll come out fairly easily.

The stator bolts were the same, had to add heat and they came out without a problem,.

I re-used all the original bolts as they weren't damaged.

Too late now, but I didn't even un-plug the stator cover from the wiring harness.

I put a short, STRONG stool next to the bike, popped the cover off and set it

on the stool and worked right there. Saved lifting the tank, finding the harness, etc,

piece of cake..

For the new cover, just put a clean, doubled over towel on the stool to the new cover

looking new...