Well, I got the shifter down into first gear using a pair of channel-lock pliers to turn the drum. I ran it back up as far as third, then back down to first, turning the shift drum with the pliers while turning the tranny shaft with my other hand. So it looks like the actual gearbox and shift drum are OK.

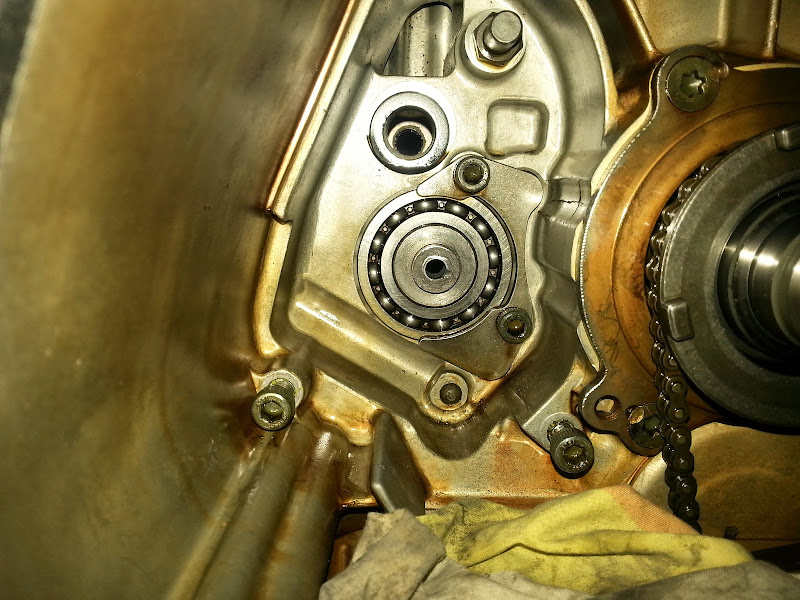

I successfully drilled the shift drum shaft, intending to try bolting the star cam back into place. The shaft had a little dimple which got me started on center very easily. Turns out the shaft opens up after about a quarter of an inch into the interior of the shift drum. Unfortunately, my plan hit a snag there, as there's no way I can turn a tap that deep inside the tranny housing; no room for the tool. Maybe there's an extension available for the purpose, I don't know.

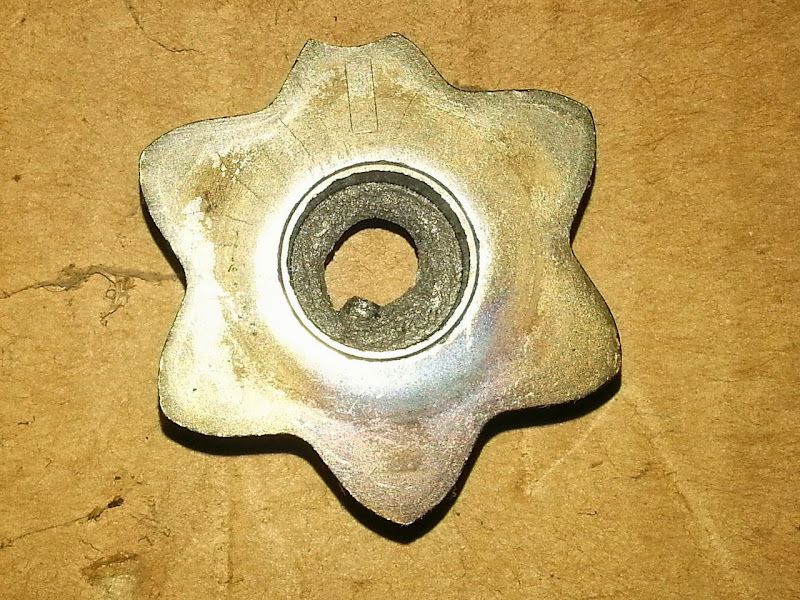

The star cam does fit on the drum in exactly one place, so the break faces mate very nicely. I don't know if it could be welded,.