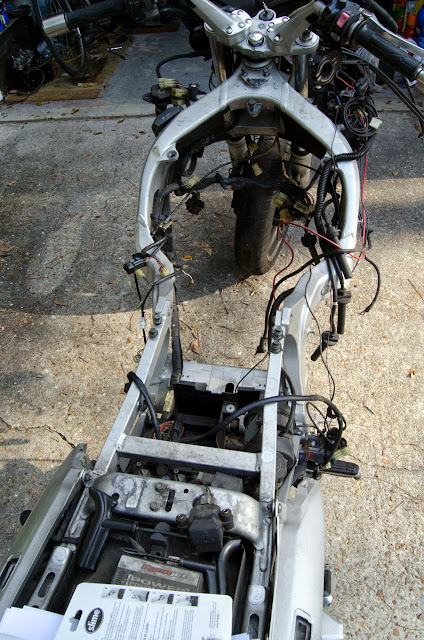

Status update. Just got the motor out. Last week I got the radiator and exhaust off, which was FAR easier than I expected. I've never tried to remove an exhaust system that didn't have HUGE issues getting the hardware loose. NO PROBLEM with these things! All eight fasteners at the head spun right off, and the two hanger bolts under the bike were even easier. Maybe an hour from draining the coolant to the picture:

So then yesterday was the motor..... I put all the crap I'd removed during the problem search back together so that the cases weren't open and I wouldn't be dropping anything into the crankcase.

(That said, while buttoning it up, I

did drop a socket and a bolt, two separate drops, not together, into the crankcase. I'd like to ask for a moment of silence in respect for the inventor of the telescoping magnet stick!!!)

So the bike is buttoned back up with bodywork still off, no intake or exhaust or cooling, all the bolts placed back into the place they go (instead of trying to mark them in baggies,) and I plan my setup.

I'm working by myself, I have nothing with which to rig a hoist to get the frame off the motor, so I start taking stuff off with an idea to plan something as I go and hope for the best.

Bike is on the centerstand in the garage, with the centerstand on a pair of 2x4s for height. I removed the rear wheel and the drive shaft, which is all you have to do to free the engine mechanically from the bike. I put a board under the oil pan and jacked it up there, then I removed the front wheel and forks for clearance to the engine, and found that I could press down on the back of the bike and lift the front quite easily at that point. I stuffed the rear axle into the rear wheel, then put the stub of the axle into the swingarm, making a single-sided swing arm out of it. (Final drive is off, remember.) There's not going to be any serious weight on the wheel, it's just going to keep the bike from rocking too far back. Remember the centerstand is elevated about 3 inches or so. I put the top case on and put four bricks in it as a counterweight.

Disconnect electrical connections to the engine (easy checklist in the service manual) then start removing bolts (again, easy checklist.) Lowered the jack as far as it would go under the motor, then grabbed the frame and raised it. The motor tilted forward a bit as the frame came up, so I braced that with some more scrap lumber and tried again. Tilt the frame up, roll the motor forward. Engine out by myself, no lifting!!!!!

With the engine out of the way, I put the front end back on, then removed the hacked rear wheel, replaced the final drive and installed the rear wheel correctly, now I can roll the lightweight bike out to the shed to get it out of the way.

I have the parts on hand from

hppants, salvaged from

Patriot's bearing-failure motor, and I haven't been able to retrieve

Radiohowie's motor, despite having coworkers in central Florida on

two separate occasions, both equipped with contact information and vans. There's one more shot at that coming up soon, which if unsuccessful will force me to make the trip down and back myself.

Swapping the head from my motor to his should be much easier than turning this thing over and splitting the case, but OTOH I have the needed parts here on hand, including the shift drum and 2nd and 5th gears (and shift fork, just in case, to correct the skipping-under-load that I, too, have begun to experience in second gear.) But 31 bolts!!! 10 of which are stretch bolts and have to be new. And no gasket, but sealant. Which makes separation and cleaning a bit odd, I'm guessing. That's where

Ionbeam's

earlier answer about head swap vs split case comes from.