Donal

Well-known member

Excellent work and very good description. That should give a lot of people (me included) the confidence to tackle an engine removal/swap on their own.

I'm working by myself, I have nothing with which to rig a hoist to get the frame off the motor, so I start taking stuff off with an idea to plan something as I go and hope for the best.

Bike is on the centerstand in the garage, with the centerstand on a pair of 2x4s for height. I removed the rear wheel and the drive shaft, which is all you have to do to free the engine mechanically from the bike. I put a board under the oil pan and jacked it up there, then I removed the front wheel and forks for clearance to the engine, and found that I could press down on the back of the bike and lift the front quite easily at that point. I stuffed the rear axle into the rear wheel, then put the stub of the axle into the swingarm, making a single-sided swing arm out of it. (Final drive is off, remember.) There's not going to be any serious weight on the wheel, it's just going to keep the bike from rocking too far back. Remember the centerstand is elevated about 3 inches or so. I put the top case on and put four bricks in it as a counterweight.

Disconnect electrical connections to the engine (easy checklist in the service manual) then start removing bolts (again, easy checklist.) Lowered the jack as far as it would go under the motor, then grabbed the frame and raised it. The motor tilted forward a bit as the frame came up, so I braced that with some more scrap lumber and tried again. Tilt the frame up, roll the motor forward. Engine out by myself, no lifting!!!!!

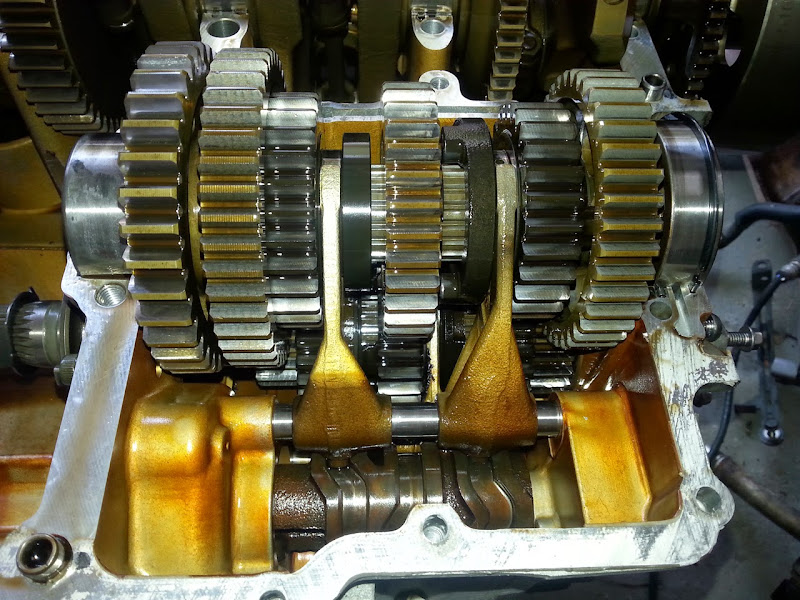

Stupidity retracted. You'll be getting a whole new trans when you do the head swap.Swapping the head from my motor to his should be much easier than turning this thing over and splitting the case, but OTOH I have the needed parts here on hand, including the shift drum and 2nd and 5th gears (and shift fork, just in case, to correct the skipping-under-load that I, too, have begun to experience in second gear.)

Yeah, well, thanks, but we'll see how it goes on installation......Pure Genius. Let me be the first to nominate you for the FJR "MacGyver" Award for that procedure!

Good mechanic, I agree with his concerns. I had those same concerns with my valve killer. Since I was a leader in crushing valves there was no history to review so we chose to err on the side of caution and checked everything. My valve train was so crushed that it broke valves and damaged the head casting causing the casting to need replacement. This is just about the worst possible damage a no clearance cylinder head can have.BTW, a mechanic friend of mine suggested I not use 'howie's engine, as he would not trust the pistons after they've hammered the valves. Cracks, whatever. But it seems I've read of cylinder head being repaired or replaced after such an event and the bike continuing along fine. Didn't Ionbeam go through that?? Thoughts??

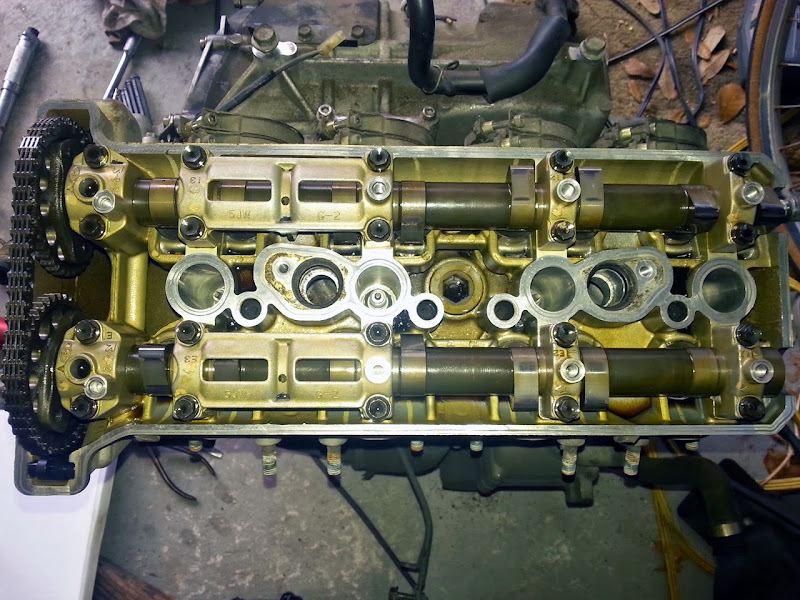

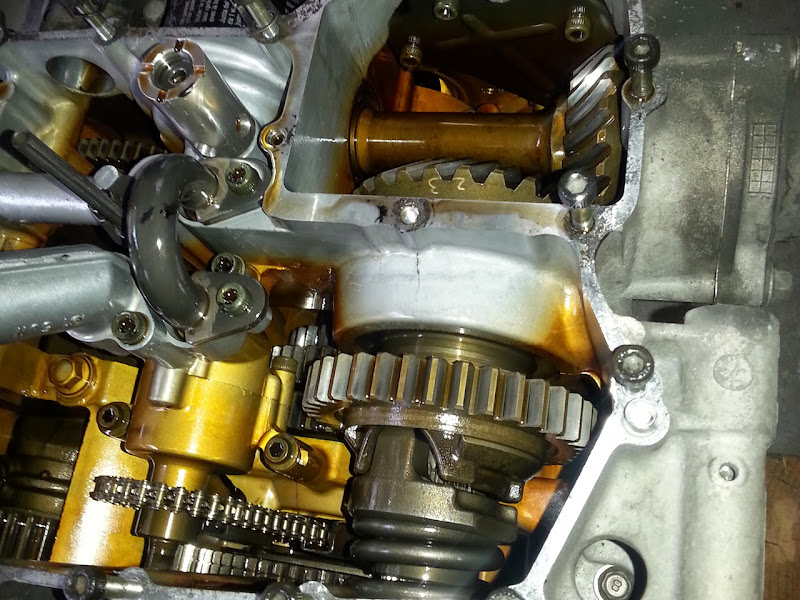

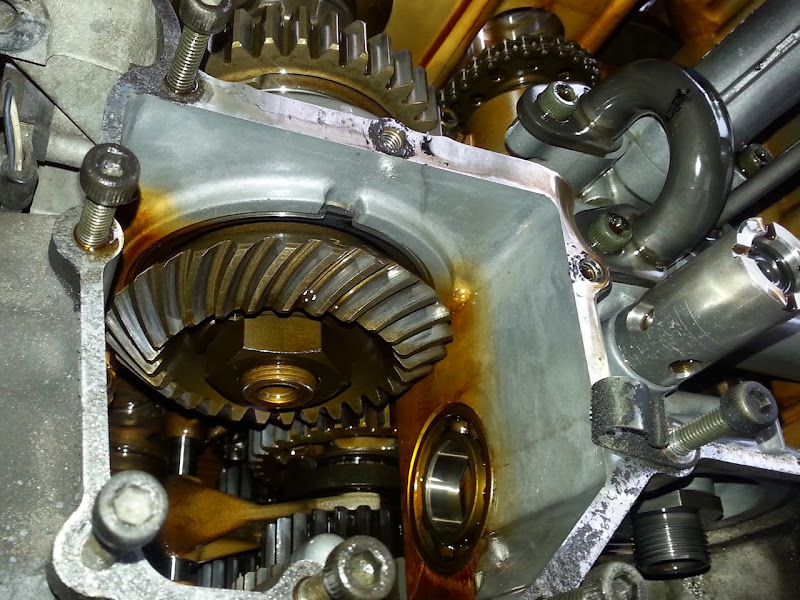

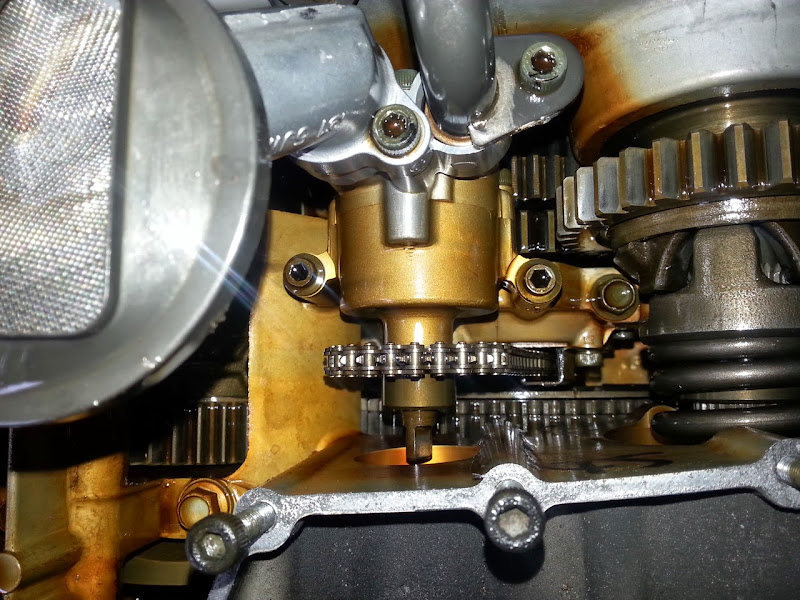

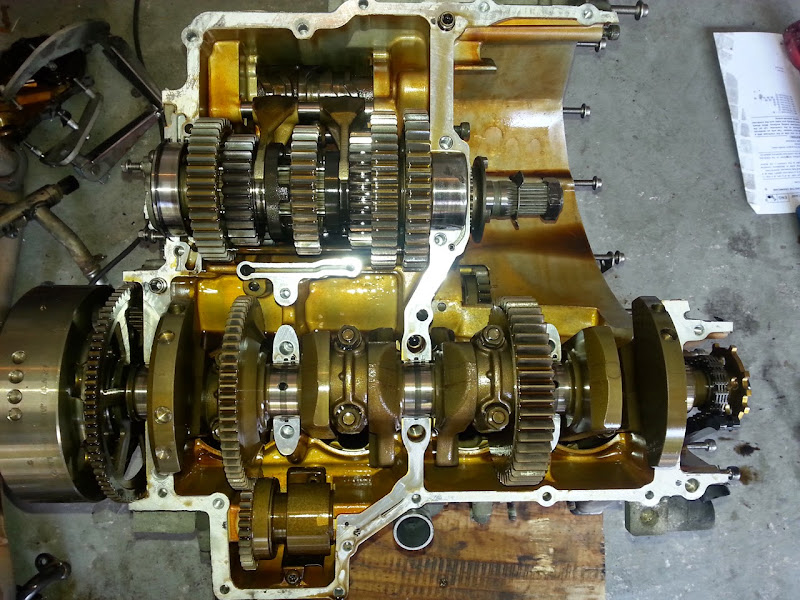

Damn Walt, you just rip into an engine like it was something as trivial as changing the oil, amazing. Can't wait for the picsWell, since I've had so much trouble fetching Radiohowie's motor, and I have parts on hand salvaged by hppants from Patriot's bearing-failure motor, I've started in on the case split.

My car smells of anti-freeze every third time I drive it. Not every time, and it's losing coolant, but not a lot, so somehow I don't trust it for a 700-mile round trip. I've had co-workers down there twice during this time but they've not made the connection, so I PM'd 'Howie and let him know he was stuck with the lump for a while longer.

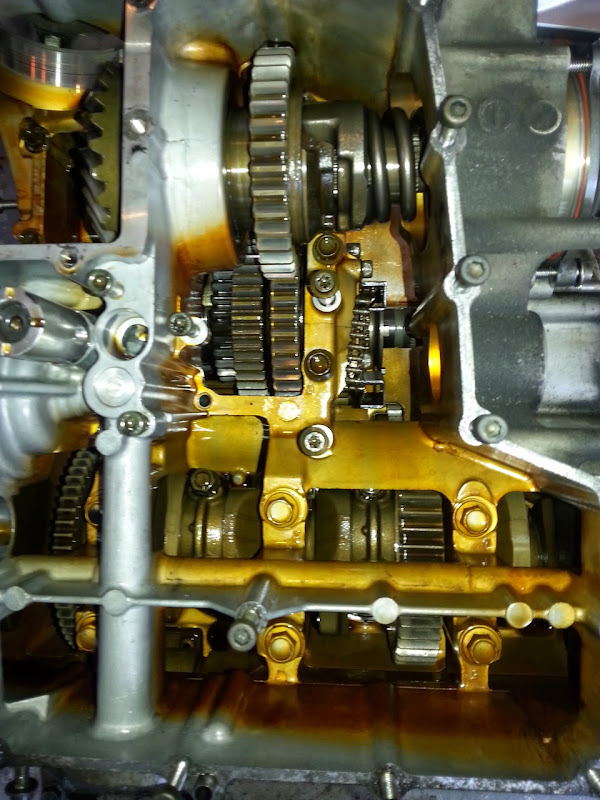

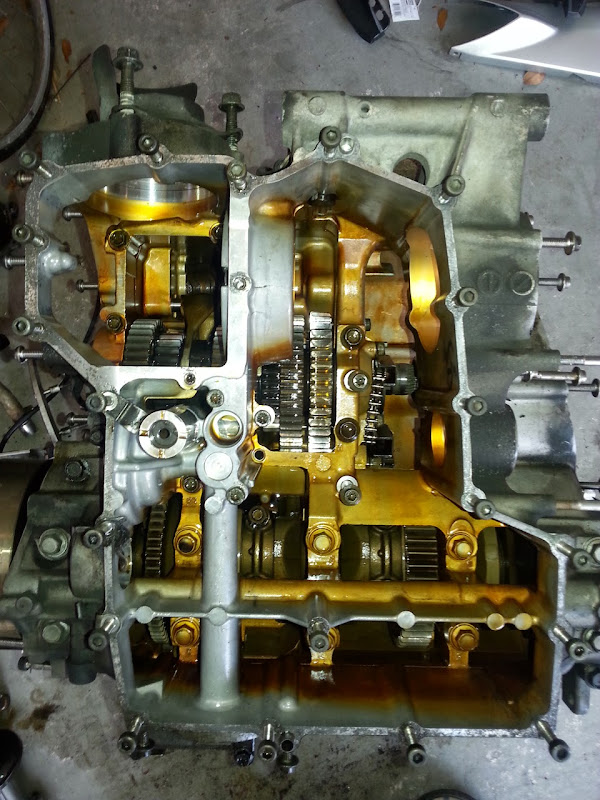

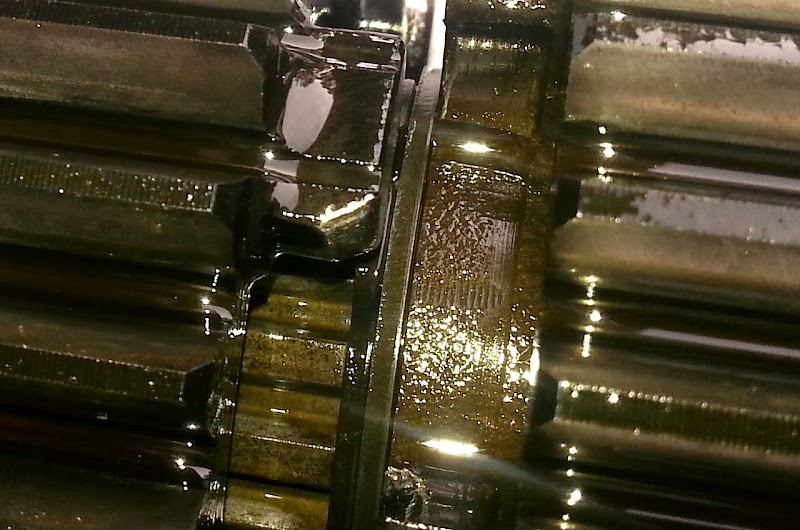

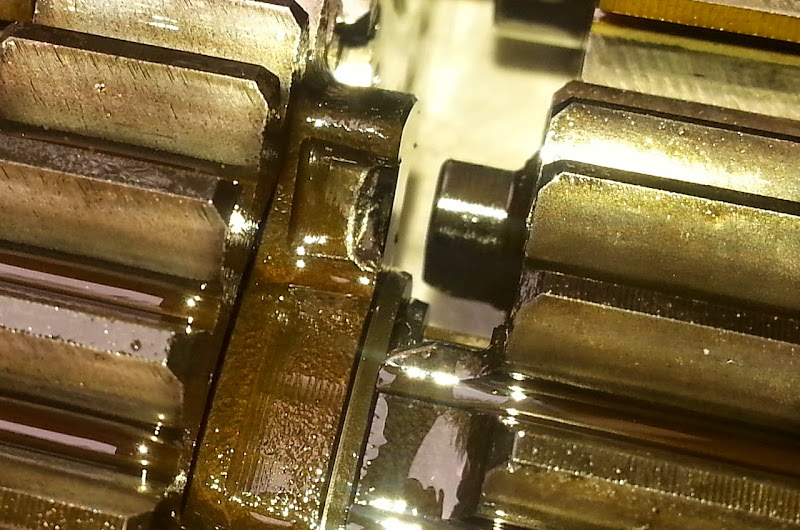

Today I got the motor turned over, the side covers off, oil pan off, oil pump and clutch basket out, and the shaft out that feeds the u-joint. I have to get another socket to get the middle gear shaft out, I already had to get a 30mm for the clutch basket nut, now I need a 36 for the middle gear axle. I think I'll just leave computers and open a bike shop.

Well, since I removed those bolts from this engine and know how smoothly they came out, I don't think that's really a concern.Walt, I just had a thought.....

While the motor's out, I'd suggest putting time-serts into the four front motor mount lugs. Extra $$$, I know, but you don't want to discover stripped or "pulled-out" threads upon re-installation of the motor. DAMHIK.