Some comparisons made today, and the tough decisions of re-using my parts or using

Patriot's parts sent over by our pal

hppants. Tough decision there.....

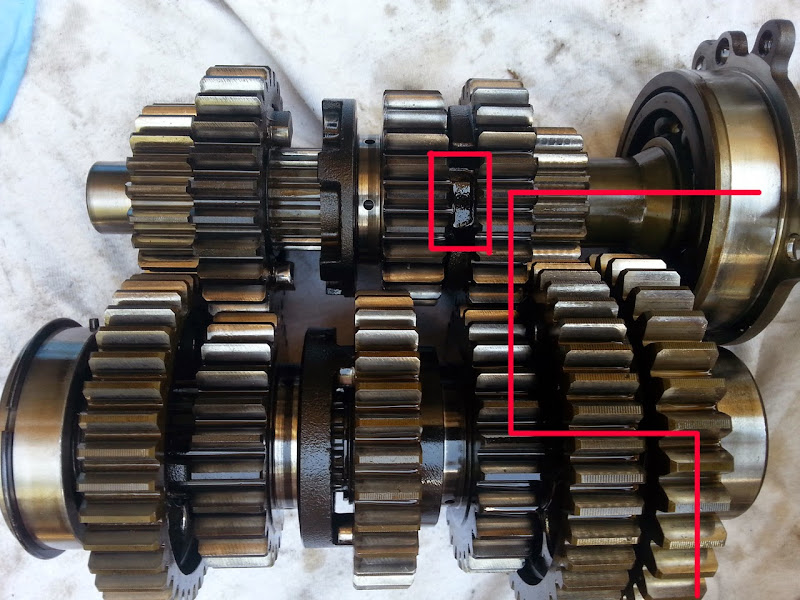

Center shift fork (4th and 5th)

And my statement earlier that this is the 5th gear fork and thus worn heavily is half wrong. It is the 5th gear fork, but the grungy side is the side for 4th gear!!!

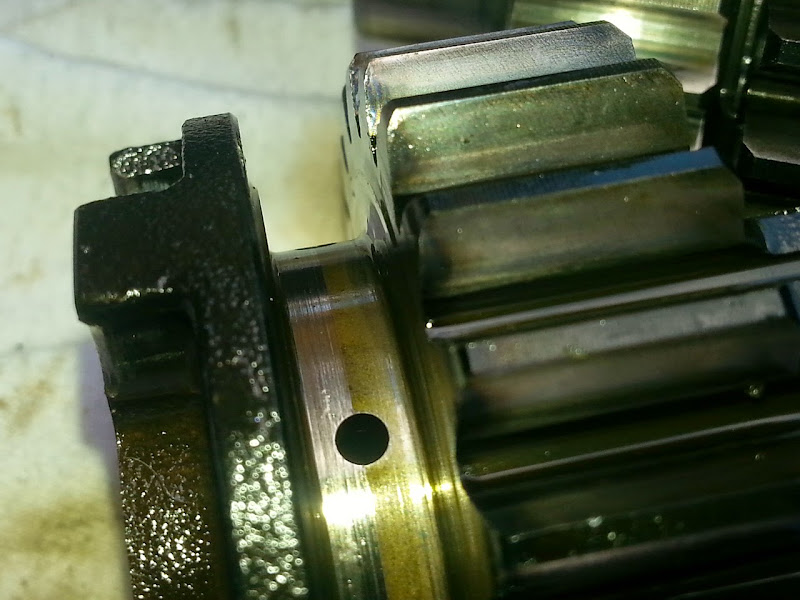

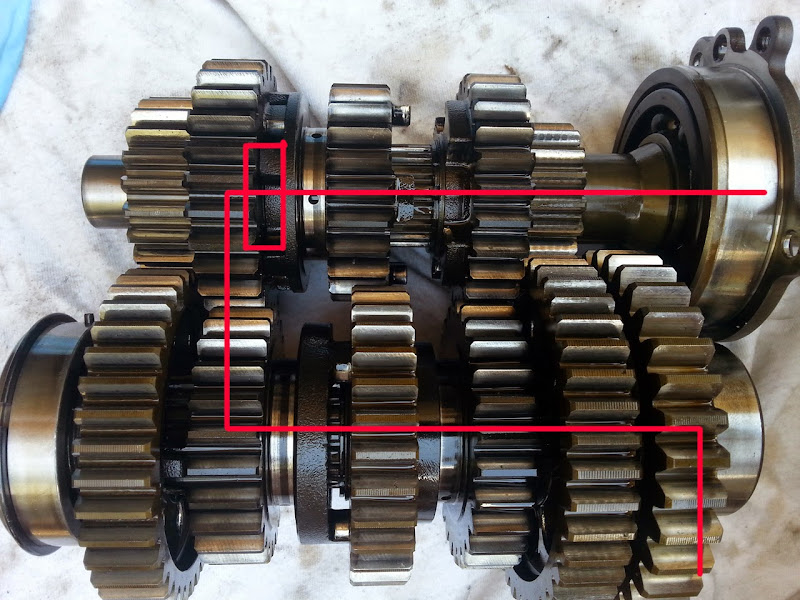

Here's my third gear wheel, looking into the groove the worn fork rides. This wheel is moves left to engage 5th, and right to engage 4th.

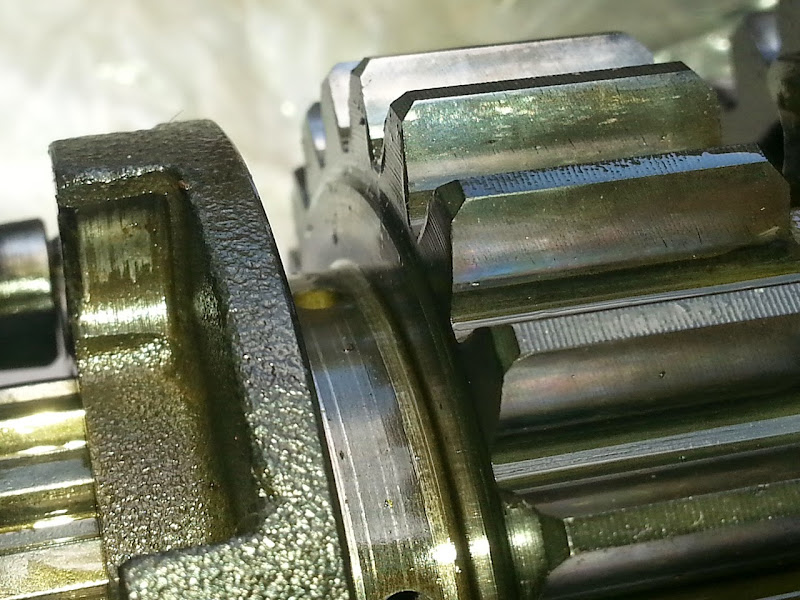

Here's the same wheel from Mike's transmission. Note the ridge on the 4th-gear side of the fork groove which is gone on mine!

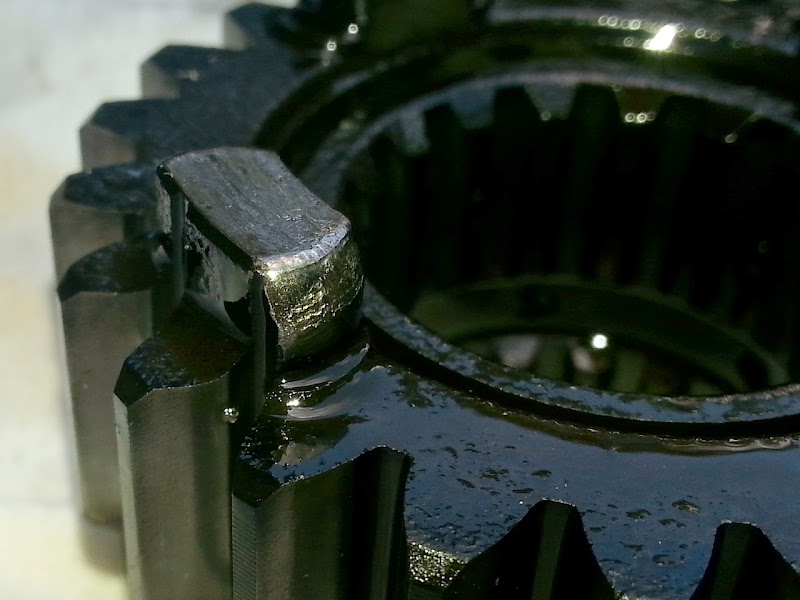

Another comparison. The 4th-gear dogs on mine.....

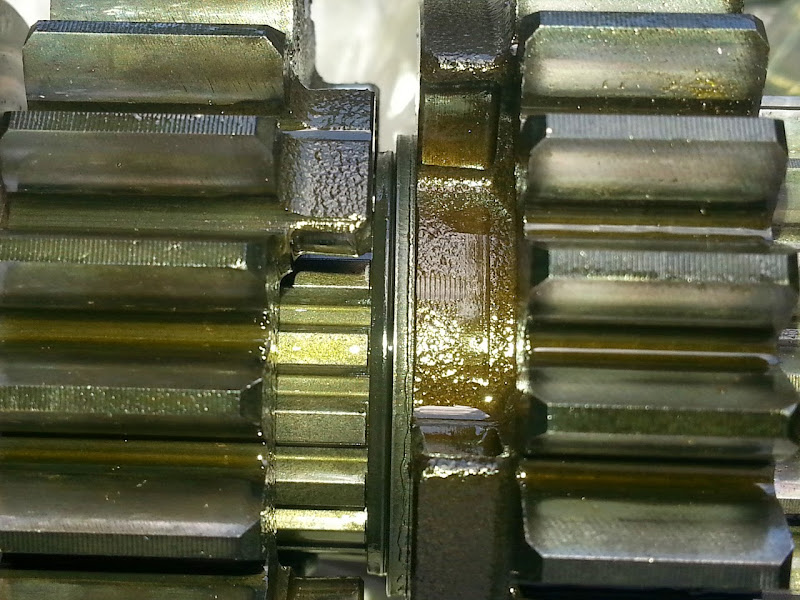

.... and on Mike's

Now for some fun. If you want to see how the shifting works in this thing, read on. If you already understand the shifting, or if you could care less, then go find something else to do. I've always been a little curious about this myself. I've seen the Youtube videos about motorcycle shifting, but some of them suck, although some are rather clear. Most show 6-speed boxes, though, and I was wondering how our missing ratio compared to those.

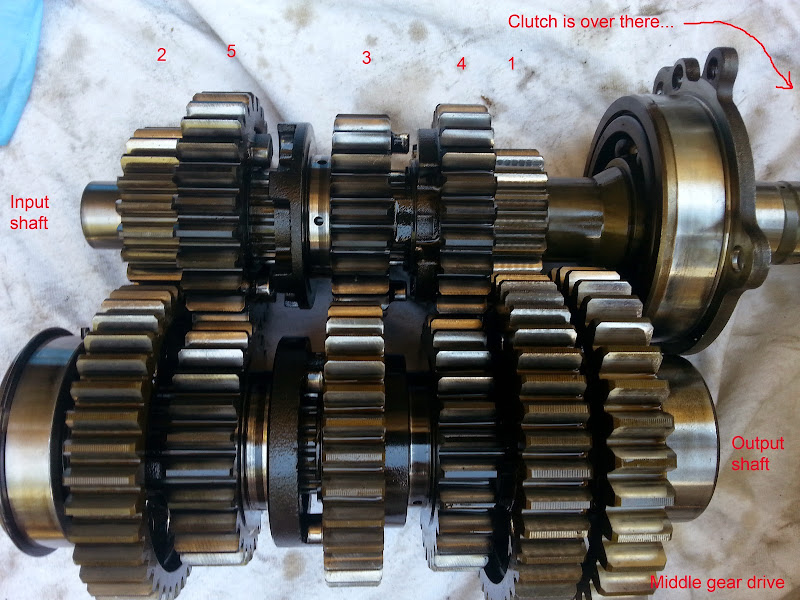

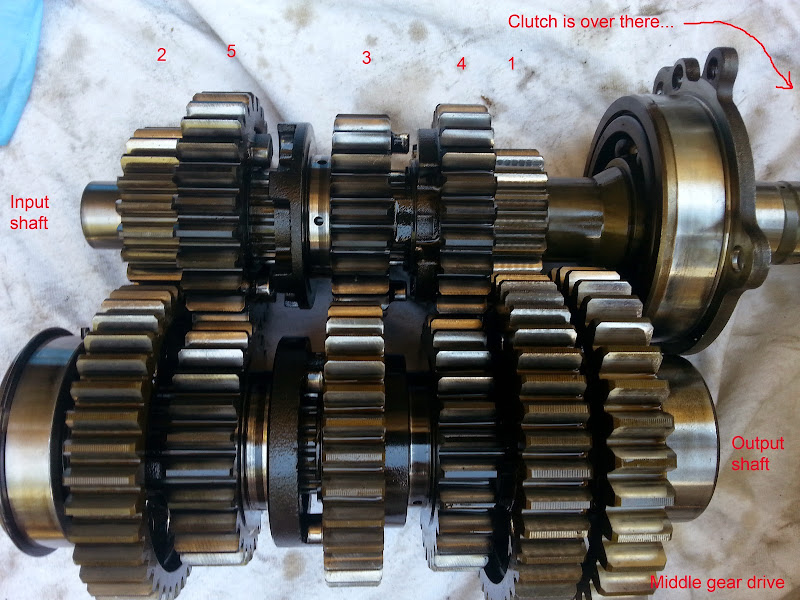

Here's a shot of the transmission shafts set as they would be in neutral. The shaft at the top is the input shaft, driven by the clutch. The shaft at the bottom is the output shaft, driven by whichever gear pair is actually engaged. In neutral, it's obviously not driven. The big gear on the right of the output shaft is splined to the shaft, and drives the middle gear shaft, which has the bevel gear which drives the output shaft to the u-joint to which the drive shaft to the rear wheel is attached.

If the crankcase were made of Star Trek's "transparent aluminum," this is the view you'd have from behind the engine looking forward, assuming the shift drum and forks were also transparent.

The gear pairs are labelled 1 through 5. One wheel for each gear is splined to its shaft, the other freewheels, allowing all the gears to stay meshed all the time, giving the term constant-mesh gearbox. Selection of ratios is done by sliding some of the wheels back and forth so the dogs on the sides mate, locking adjacent wheels together.

On the input shaft, 1st, 2nd, and 3rd are splined to the axle (1st is actually machine as

part of the axle!) while 4th and 5th spin freely. On the output shaft, 4th and 5th are splined to the axle while 1st through 3rd spin freely. You'll notice that the gears are not in order on the shaft. The idea is that each gear wheel is adjacent to the other type of wheel, free, spline, free, spline, etc. Gear selection is done simply by sliding a wheel into the adjacent one, locking them together so that the free wheel is no longer free. When both wheels of a specific ratio are locked to the shaft, that ratio is selected, as all the other ratios have one wheel spinning freely. So as pictured, with no dog engaged, the input shaft is driven by the clutch but each ratio has one wheel spinning freely, so there is no propulsion.

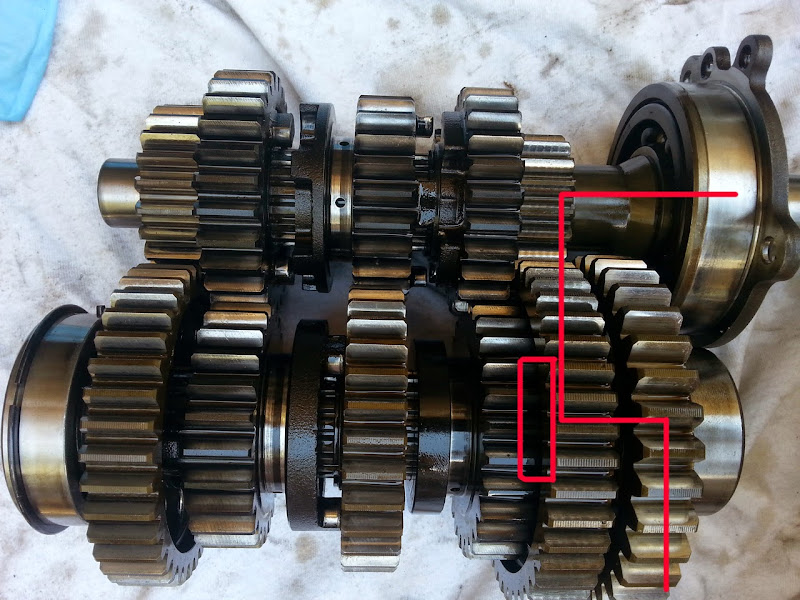

Now you kick the shifter down into first (or up for you AE guys....) and the right-hand fork moves to the right, sliding the 4th-gear output shaft wheel into the 1st-gear output shaft wheel, which until that point was free-spinning. First gear's wheel is now locked to the axle by being engaged with the next wheel over, which is splined, and transmits the torque into the axle. I drew a line showing the engaged gears, and a box showing the engaged dogs.

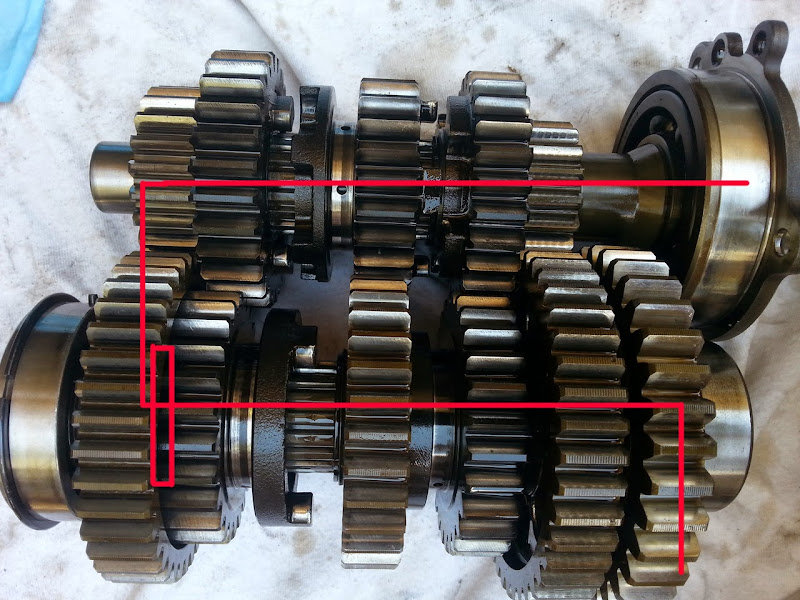

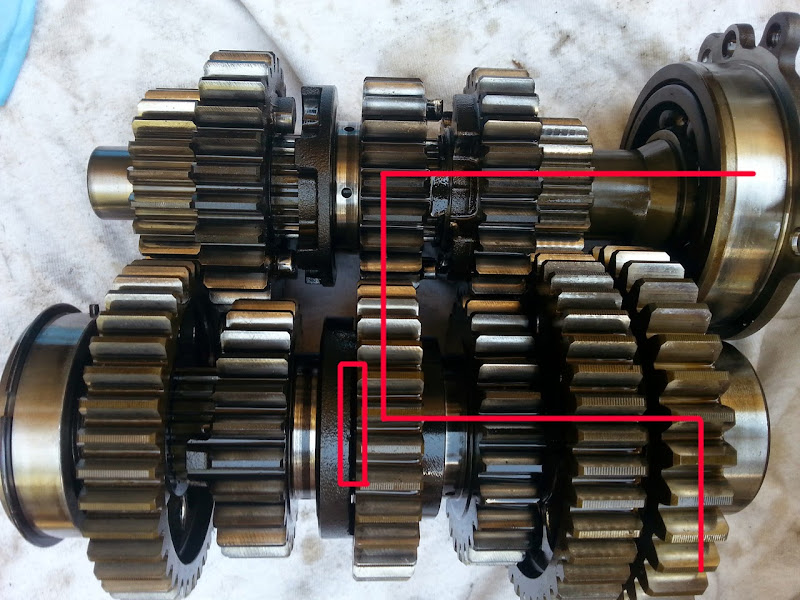

Now the same illustrations for 2nd, 3rd, 4th, and 5th.

The right fork is returned to its neutral position, and the left fork slides the 5th-gear output wheel into the 2nd-gear output wheel. 2nd-gear output was free-wheeling, now it's locked to the shaft by the splines on the 5th-gear output wheel.

3rd. The left fork moves across its neutral position, all the way to the right, and engages third gear on the output shaft.

4th. The left fork returns to its neutral, and the center fork slides the splined 3rd-gear wheel into the freewheeling 4th gear wheel on the input shaft.

And 5th, also handled by the center fork on the input shaft.

Now back to that thought about our missing ratio..... To put a 6-speed in the FJR, which so many people seem to think is a Necessary Thing (I am not among them....) you would have to add a pair of wheels and size all the wheels differently, change which pairs the sliding wheels engage and which order, and either make the axles longer for room, or make the gearwheels thinner so they all fit. Longer axles means all-new castings for the crankcase, and thinner gearwheels probably means weaker gears. Oh, yeah. New shift drum to make the extra selection.