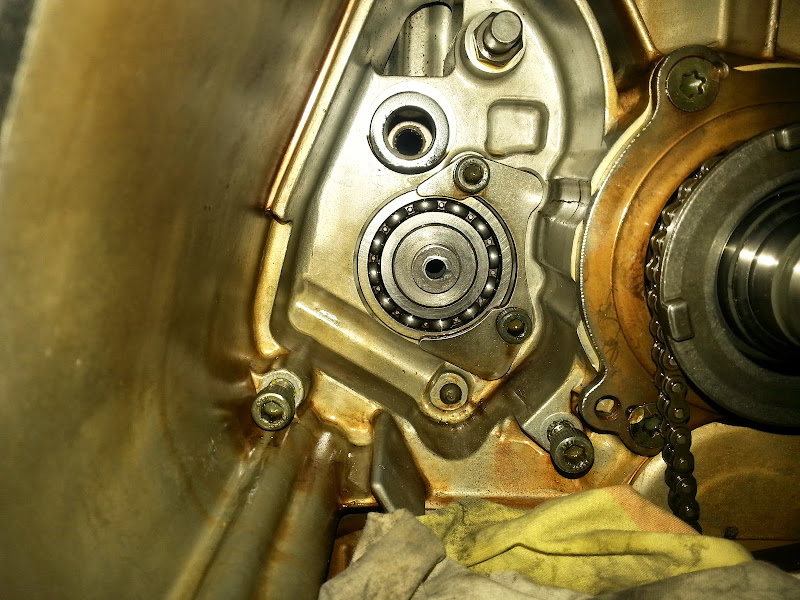

Well, I got the shifter down into first gear using a pair of channel-lock pliers to turn the drum. I ran it back up as far as third, then back down to first, turning the shift drum with the pliers while turning the tranny shaft with my other hand. So it looks like the actual gearbox and shift drum are OK.

I successfully drilled the shift drum shaft, intending to try bolting the star cam back into place. The shaft had a little dimple which got me started on center very easily. Turns out the shaft opens up after about a quarter of an inch into the interior of the shift drum.

Unfortunately, my plan hit a snag there, as there's no way I can turn a tap that deep inside the tranny housing; no room for the tool. Maybe there's an extension available for the purpose, I don't know.

It's probably academic anyway, as while hand-fitting the parts I found that the shift ratchet thingamajig has a tab that will occupy the space the bolt head would be in, and without access to a fourth dimension to fold the parts through they will interfere with each other, like some peoples' valves and pistons, just not as catastrophically.

The star cam does fit on the drum in exactly one place, so the break faces mate very nicely. I don't know if it could be welded, I don't know if epoxy would hold up on it. I had planned on some epoxy under it with the bolt to ensure no rotation of the cam against the shaft, and some red loc-tite on the bolt, but the bolt plan appears to be out the window. If I'd been able to do that, I'd be riding the bike tomorrow. Maybe Sunday.

My employer has a crew working next week in Orlando, I think I'll see about diverting one of the vans a little ways down I-4 and US 27 (or whatever road they'll need down there....) while they're in the neighborhood......