Brodie

Darksider #16 - and Proud of it !

Gentlemen,

Thought I'd add to the discussion...

My bike gave me several episodes of -nothing- the last couple of months when switching on the key. I cut the cord tie, sprayed contact cleaner in the neither regions of the switch, and even jiggled the wires to some success. With my 3 week vacation coming up I decided to open it up and find out why my switch was intermittent. Thanks to this forum (all of you) I had no reservations about removing the top fork bridge and performing surgery on the ignition switch.

Here are my findings...

Good news...

Upon backing out the security screws and removing the wiper plate I found all four wires were still attached.

The switch had some dirt in it, but no built up spoodge gumming up the works.

The lock cylinder was in great shape for 32 thousand miles, the fork lock was in good repair.

This left me with the basic question... What happened? What is the failure mode on my bike?

I had a closer look at the components. What we have is a plastic wiper plate with brass contacts riveted on and wires soldered to their back side (slight wear on the wiped surface but otherwise in good shape). The lock cylinder is shaped into a shaft which when turned cams a link that moves the lock pin in and out. This shaft also turns a plastic carrier that mounts four copper stampings which act as spring loaded wipers. These copper wipers have two barbed legs engaged in small rectangular holes cast in the carrier. Each wiper has its own spring enabling it to float against the wiper plate. These wipers also have three small contact points embossed on their faces.

Upon closer examination of one of these wipers I noticed heat induced discoloration and a bit more wear on the hottest contact point.

If you look closer at the carrier itself, right next to the overheated wiper is a melted spot in the plastic.

This is the smoking gun I was looking for!

The melted area pinches the wiper so it does not float as easily. When the key is turned the wiper is sliding across the wiper plate and sometimes catches on the edge of the brass contact area. Occasionally it tilts and hangs up in the carrier preventing all three contact points to do their job.

That is the failure mode for the switch on my bike. Now to figure out the root cause.

HEAT - Why are things getting hot in the first place? All the electrical farkles I put on my bike come straight off the battery thru an added fuse then on to a sub panel. I am not putting any more demands on my bikes original wiring. Heat is caused by resistance in an electrical circuit. The main fuse is rated at 50 amps. The electrical path then goes straight to the ignition switch then back to several more fuses and on to the rest of the bike. Think of it, 50 amps, carried by 12 gage wire a good 3 feet through an electrical switch with a very small contact point.

In my opinion this is a very poor design for that kind of amperage. That setup, I believe, was designed several decades ago when Yamahas were small and had a small load on their electrical systems. It is not up to the demands of a modern bike with the type of systems in use today.

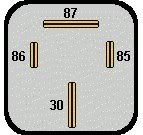

I decided to make a change. Relays are designed to use a very small amount of current to switch a much larger load. I found a relay rated at 70 amps to put between the main fuse and the ignition switch. Pictured below is the relay I installed on the ignition switch pigtail located under the fuel tank heat shield.

Its been on the bike for several days now and not given me a lick of trouble. Notice I left the main harness alone on the bike, my standard practice is to always modify the pigtail and leave the main harness intact. That way if I blow it, its a lot easier to replace a component then to repair the main harness.

Time will tell how this set up will hold up.

Many thanks to Barabus, and others, for the time he took to share with us the work he did to his switch.

Brodie

Thought I'd add to the discussion...

My bike gave me several episodes of -nothing- the last couple of months when switching on the key. I cut the cord tie, sprayed contact cleaner in the neither regions of the switch, and even jiggled the wires to some success. With my 3 week vacation coming up I decided to open it up and find out why my switch was intermittent. Thanks to this forum (all of you) I had no reservations about removing the top fork bridge and performing surgery on the ignition switch.

Here are my findings...

Good news...

Upon backing out the security screws and removing the wiper plate I found all four wires were still attached.

The switch had some dirt in it, but no built up spoodge gumming up the works.

The lock cylinder was in great shape for 32 thousand miles, the fork lock was in good repair.

This left me with the basic question... What happened? What is the failure mode on my bike?

I had a closer look at the components. What we have is a plastic wiper plate with brass contacts riveted on and wires soldered to their back side (slight wear on the wiped surface but otherwise in good shape). The lock cylinder is shaped into a shaft which when turned cams a link that moves the lock pin in and out. This shaft also turns a plastic carrier that mounts four copper stampings which act as spring loaded wipers. These copper wipers have two barbed legs engaged in small rectangular holes cast in the carrier. Each wiper has its own spring enabling it to float against the wiper plate. These wipers also have three small contact points embossed on their faces.

Upon closer examination of one of these wipers I noticed heat induced discoloration and a bit more wear on the hottest contact point.

If you look closer at the carrier itself, right next to the overheated wiper is a melted spot in the plastic.

This is the smoking gun I was looking for!

The melted area pinches the wiper so it does not float as easily. When the key is turned the wiper is sliding across the wiper plate and sometimes catches on the edge of the brass contact area. Occasionally it tilts and hangs up in the carrier preventing all three contact points to do their job.

That is the failure mode for the switch on my bike. Now to figure out the root cause.

HEAT - Why are things getting hot in the first place? All the electrical farkles I put on my bike come straight off the battery thru an added fuse then on to a sub panel. I am not putting any more demands on my bikes original wiring. Heat is caused by resistance in an electrical circuit. The main fuse is rated at 50 amps. The electrical path then goes straight to the ignition switch then back to several more fuses and on to the rest of the bike. Think of it, 50 amps, carried by 12 gage wire a good 3 feet through an electrical switch with a very small contact point.

In my opinion this is a very poor design for that kind of amperage. That setup, I believe, was designed several decades ago when Yamahas were small and had a small load on their electrical systems. It is not up to the demands of a modern bike with the type of systems in use today.

I decided to make a change. Relays are designed to use a very small amount of current to switch a much larger load. I found a relay rated at 70 amps to put between the main fuse and the ignition switch. Pictured below is the relay I installed on the ignition switch pigtail located under the fuel tank heat shield.

Its been on the bike for several days now and not given me a lick of trouble. Notice I left the main harness alone on the bike, my standard practice is to always modify the pigtail and leave the main harness intact. That way if I blow it, its a lot easier to replace a component then to repair the main harness.

Time will tell how this set up will hold up.

Many thanks to Barabus, and others, for the time he took to share with us the work he did to his switch.

Brodie