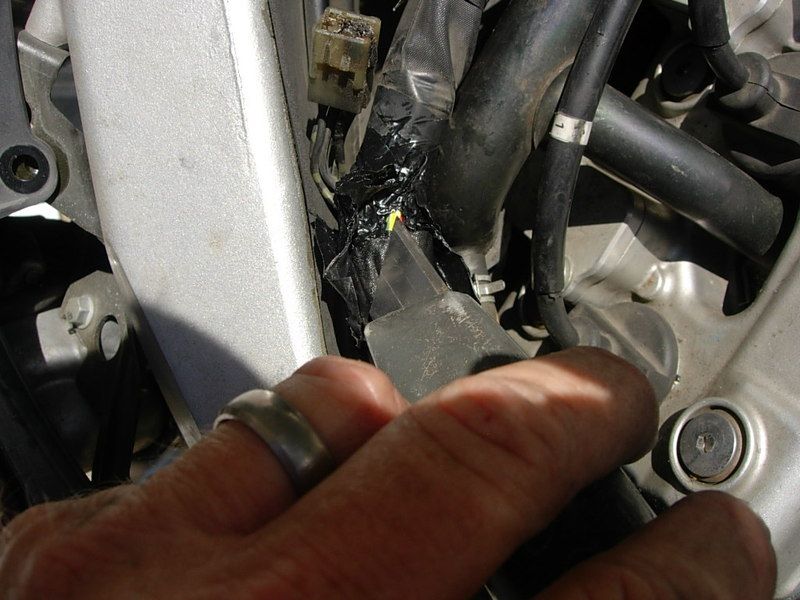

Circle shows the little chute where this section of 'T" gets pushed up into to gain slack in the engine compartment.

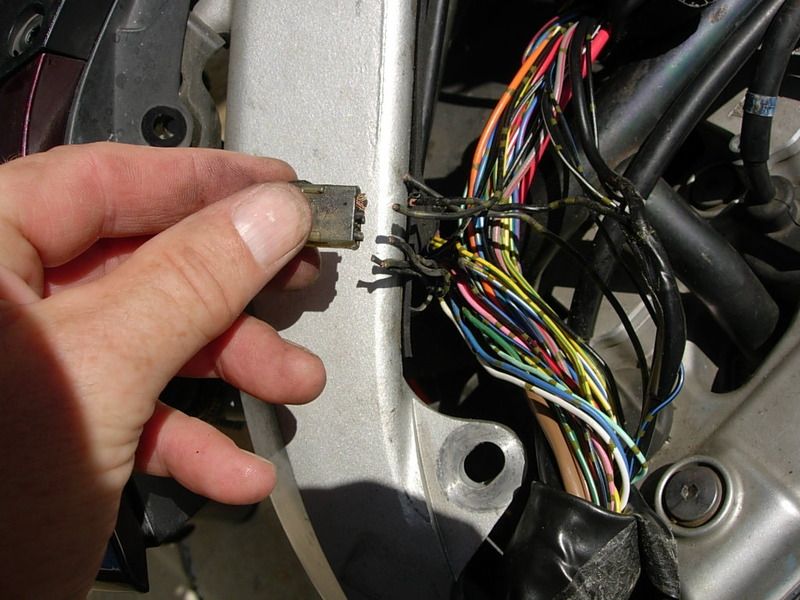

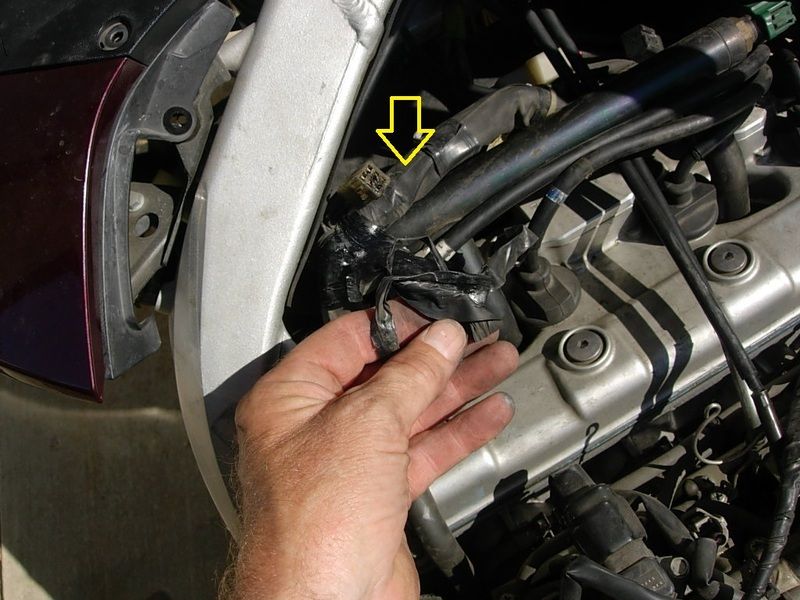

Screwdriver points to the object of my desires- the main wiring harness- to be pulled up. You can see the burned S4 spider on the right.

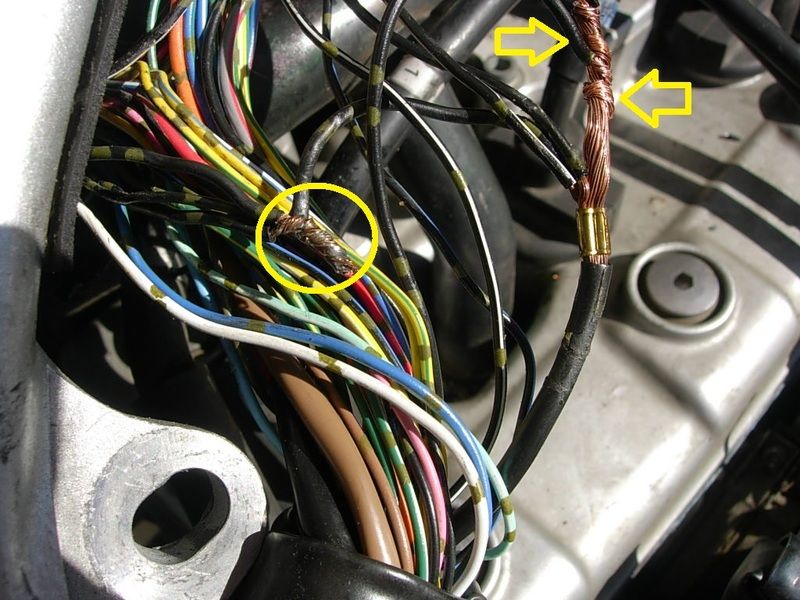

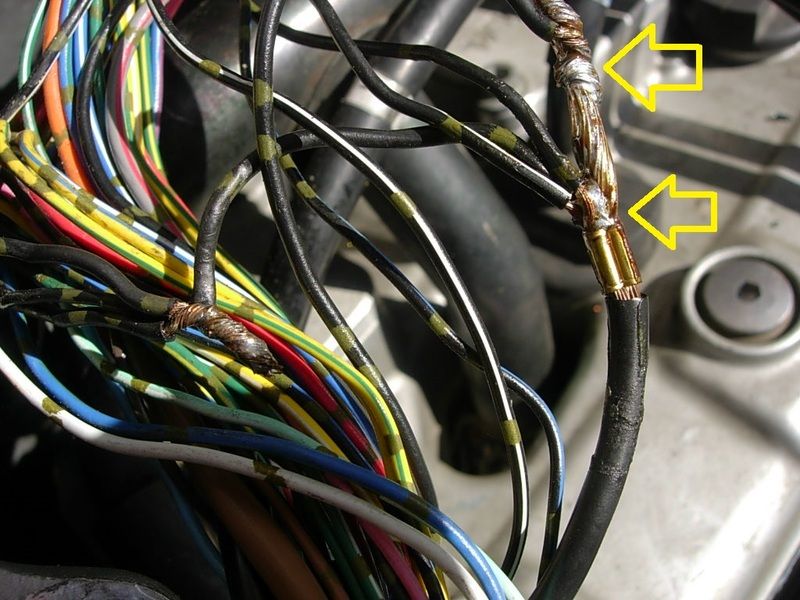

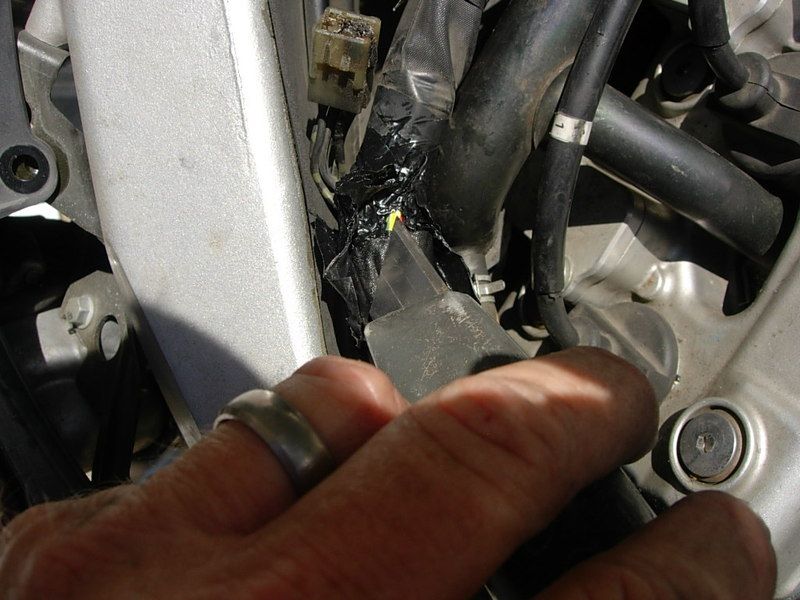

And the offending wiring in the S4. I later learned that this one small wire carries all the current collected in the spider back to the main ground wire. Also note- the straight sections of harness are covered with a folded wrap like a sticky note folded together with the sticky glue holding it closed. The 'T' section is plain ol' electrical tape.

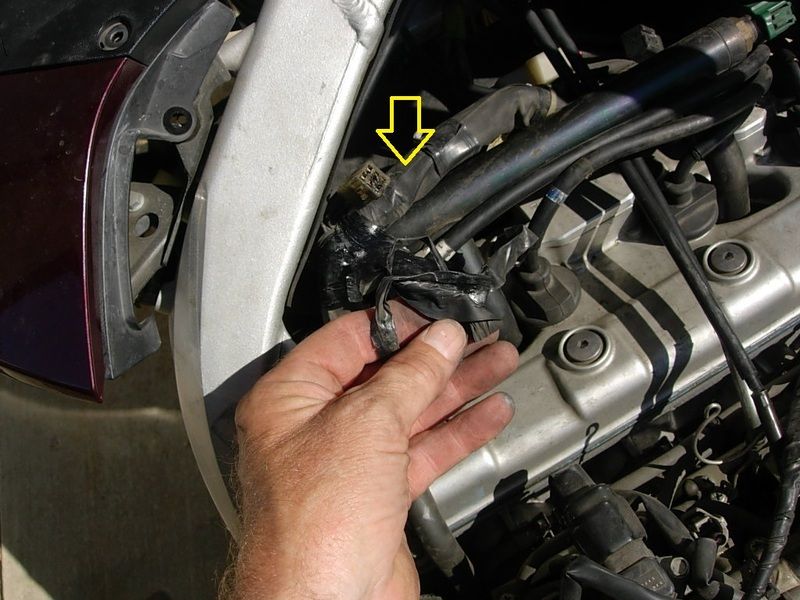

The arrow shows the coolant hose clamp removed to gain a little room. In this pic, by pushing up from the bottom and tugging up from the top you can see the harness starting to cooperate.

And now time to carefully unwrap

Once the tape is removed you can see what I meant about the sticky note-type cover

Oh hell no! Having these issues is one of the benefits of owning the bestest color FJR ever!

Screwdriver points to the object of my desires- the main wiring harness- to be pulled up. You can see the burned S4 spider on the right.

And the offending wiring in the S4. I later learned that this one small wire carries all the current collected in the spider back to the main ground wire. Also note- the straight sections of harness are covered with a folded wrap like a sticky note folded together with the sticky glue holding it closed. The 'T' section is plain ol' electrical tape.

The arrow shows the coolant hose clamp removed to gain a little room. In this pic, by pushing up from the bottom and tugging up from the top you can see the harness starting to cooperate.

And now time to carefully unwrap

Once the tape is removed you can see what I meant about the sticky note-type cover

You know Russ, if you'd paint that thing a decent color, then you wouldn't have these issues.

Oh hell no! Having these issues is one of the benefits of owning the bestest color FJR ever!

Last edited by a moderator: