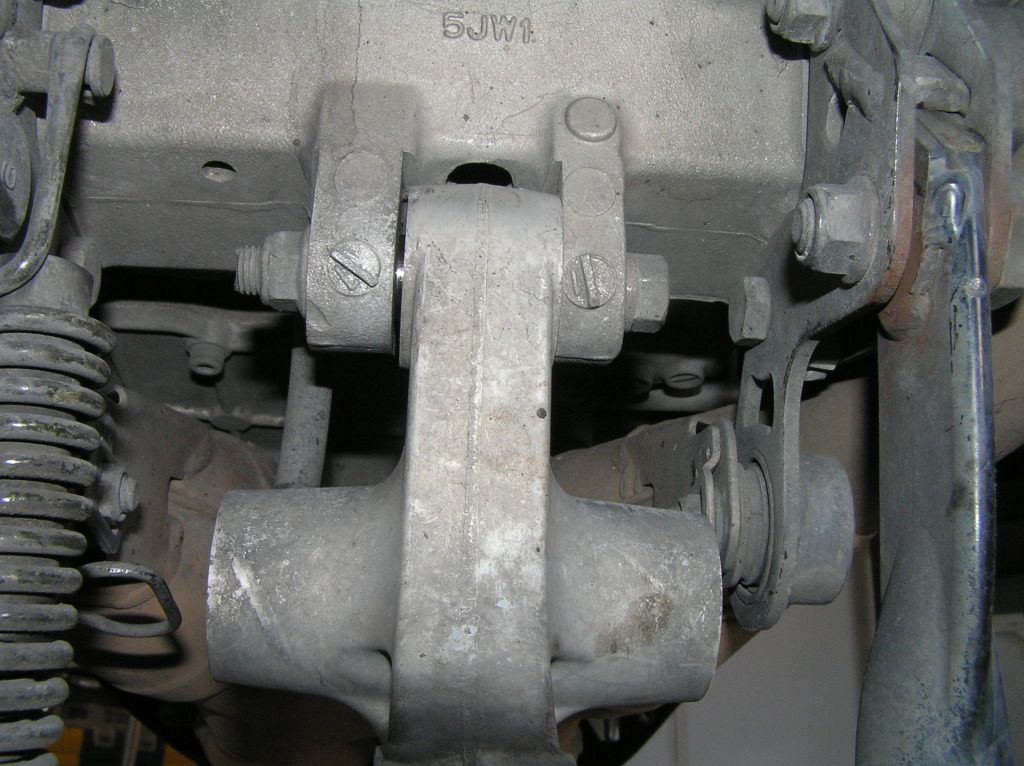

The bracket that prevents the bolt removal.

So over the weekend (on call again) I did the mod to allow the bolt and relay arm to be removed.

I used a rotary cut off wheel and small grinding stone and removed some excess material from the centrestand bracket to allow the removal of the bolt in situ. You don't have to remove the centrestand.

Metal and bolt removed

The bolt for the frame pivot link is quite long and there are 5-6 threads extending the nut when done up. I cut the threads off leaving 1 thread past the nut when fully torqued. The bolt will not come out,(the bolt head hits the exhaust), without removing a few threads.

I used a dozen or more dremel cut off wheels and grindstones to remove the metal that prevents the bolt removal, there is plenty of "meat" left on the centrestand bracket.

After grinding

It may have been easier to remove the centrestand but I didn't want to risk slinging the bike by myself.

All up it took about 6 hours to do the mod and lube, and a lot of cut off wheels.

It will make servicing the linkages real easy next time, no excuse.

Cheers