The steel rule in the photo is a six inch scale. They don't show up too well in the photo, but the graduations are in .010" and .020".

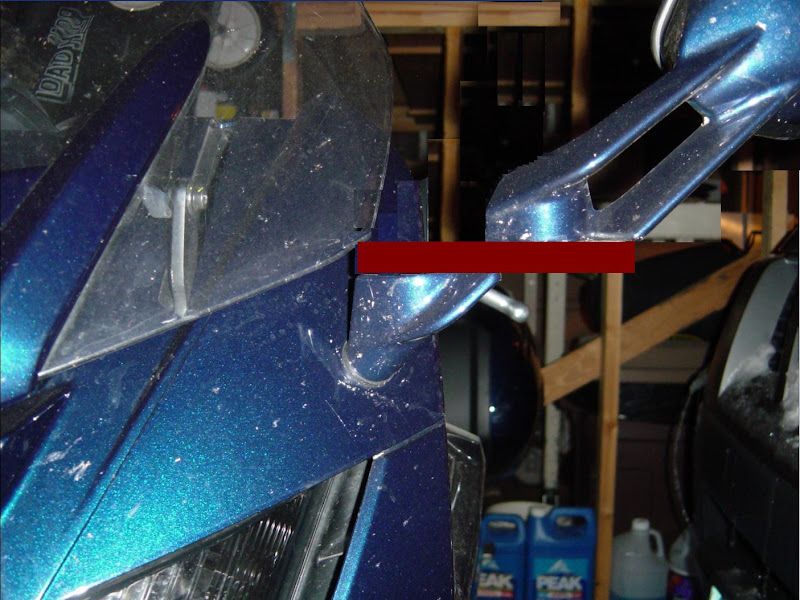

The studs on jet mechanic's mirrors are approximately 9mm longer (about .350") than what I have on my '06.

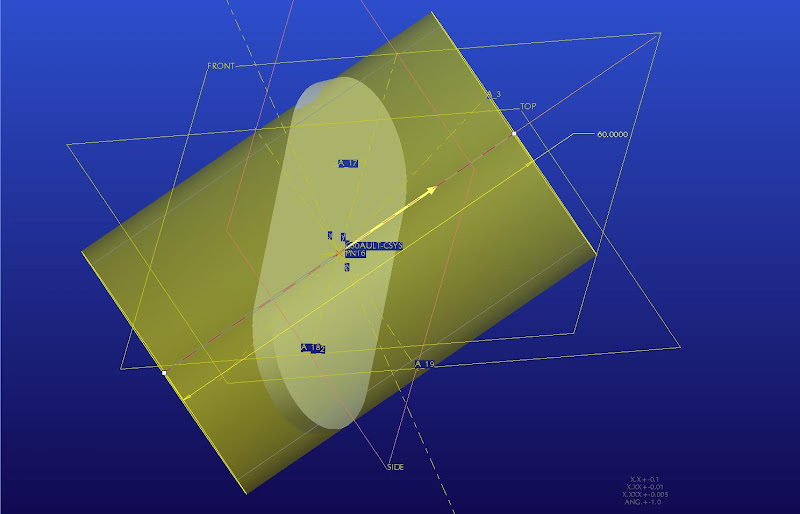

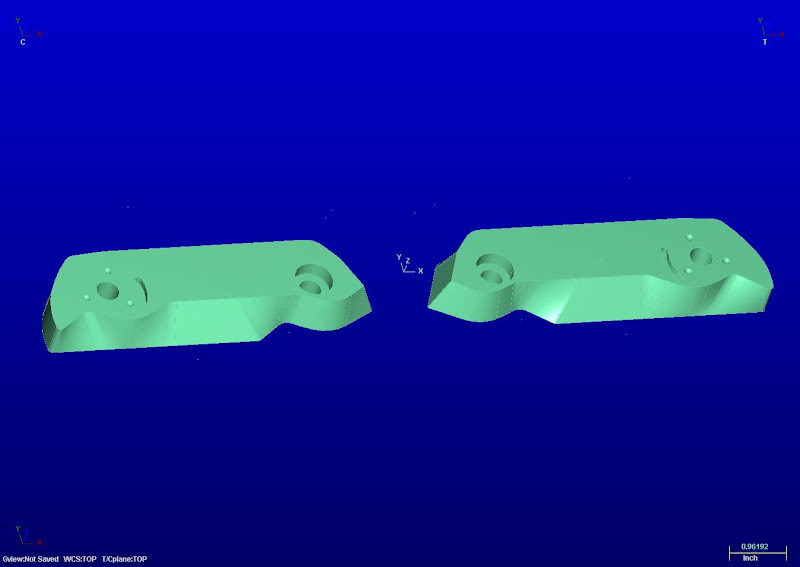

Next, I took the measurements of the angles on the fairing and tried to plug them into a CAD model. The line we are interested in is 45 degrees to the ground and 90 degrees to the centerline of the bike (front to rear). We want not only this centerline, but we when we make our diagonal cut on the spacers, we want the surfaces to follow the dimensions of the mirror base and rubber vibration dampener.

If that makes any sense, (or if it doesn't) I offer this:

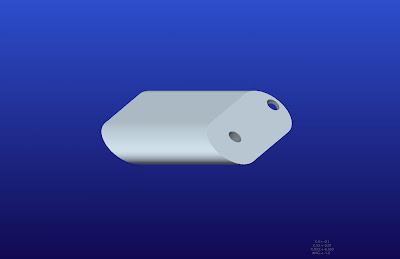

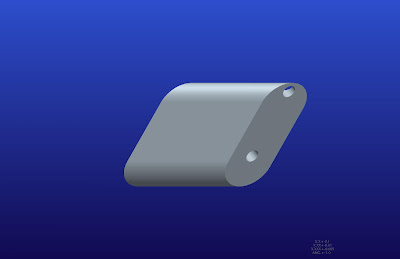

The light oval in the middle is an approximation of the rubber vibration dampener. The yellow arrow is the direction we need the mirror to move if we want an improved rear view. The transparent yellow form is an oval and about 2" (50mm) tall. I took a break after getting that far. Tomorrow I'll cut the ends parallel to the planes on the face of the dampener and add holes for the mirror studs and threaded posts where the bracket will mount to the fairing.

Remember the pasta? Maybe picturing that will help. The oval shape is produced first, the ends are cut, and those surfaces either get drilled for the mirror studs, or drilled and tapped for the fairing mount studs. This whole deal will require two special fixtures, one each for the secondary operations.

And,.. I still don't have an HID mount or the camera mount!