Fontanaman

Robin Trower

I will give Eric at Penske a call and report back.

If it doesn't stay "attached" as it should, I don't care if it's free to re-build.Too bad Townsends...you're missing out on one of the best owner-rebuildable shocks on the market.<<snip>>I know what I'll NEVER buy....

--G

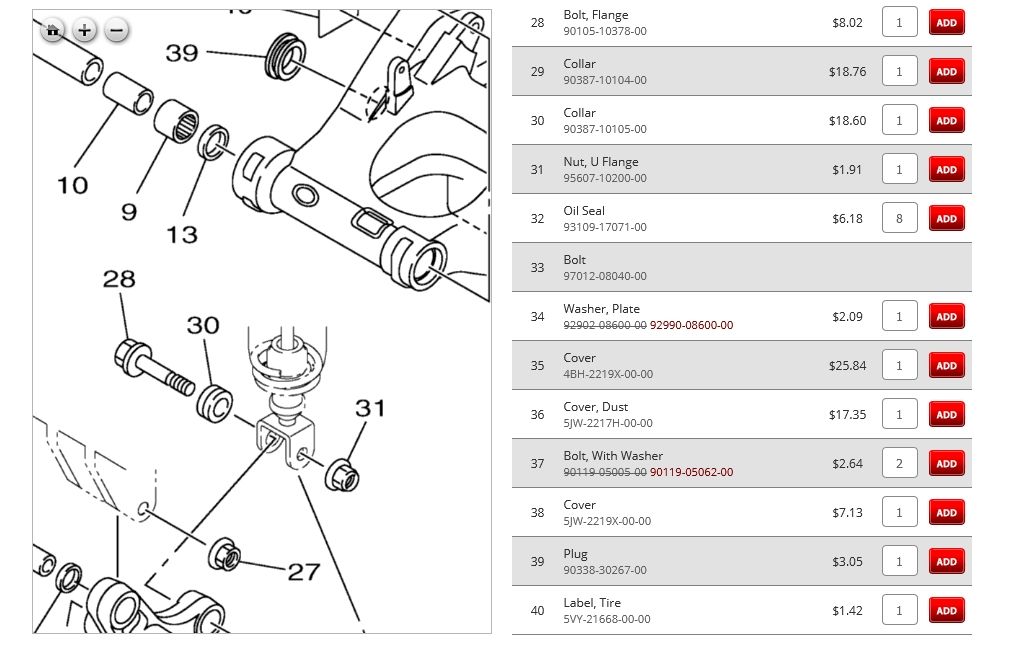

No, the easiest solution would be to slip a washer/shim/spacer with the correct OD onto the bolt before installing it. I'll be doing this to my son's (my old) FJR sometime when the weather breaks and he can get the bike down his unpaved road to bring it here for its 100k mile service.IMO, the easiest solution is machining the head of the OE bolt.

I would agree, John, except your washers are a bit too big. You want the OD to be the same size as (or slightly smaller than) the OD of the shoulder of the bolt.To me, the easiest fix is in post #255.

Or we could use ball bearings. (This is meant as a joke, by the way.. one of my favorite)I would agree, John, except your washers are a bit too big. You want the OD to be the same size as (or slightly smaller than) the OD of the shoulder of the bolt.To me, the easiest fix is in post #255.

Wow! You really don't have much experience with the legal profession, do you?(and disclaimer - we do not need another 3 page legal dissertation, I think the previous one suffices, and the points were made well.)

Enter your email address to join: