Until you do a compression/leakdown check and find issues, you have no reason to pull the head. If turning the engine over at the crankshaft bolt goes all the way around without anything other than normal compression resistance (and nothing punches through the side of the block) then there's no need to yank the head "just because."

But do those checks before stuffing the motor back into the bike!!!

EDIT: I just realized I said to do the compression check with the engine out of the bike, to make doing the head work (if needed) easier to start.

Obviously you'd need to have the covers back on it so it holds the oil you'd have to put in it, and you better strap that thing down and brace it before putting voltage on that starter to turn it over!!!

You're not going to need water, but don't forget the oil cooler and filter.

Maybe do the compression/leakdown after getting it back in the frame, but not so far along in reassembly that you'd want to commit suicide rather than pull it back out if you had to. Get it in the frame, put the side covers and oil cooler and filter on, put some oil in it, connect the big ground and starter cables. Make sure no other hot wires are laying around loose (I don't think there would be) and connect the battery back up. You won't need throttle bodies, cooling, exhaust, and all that until you're sure it's staying in.

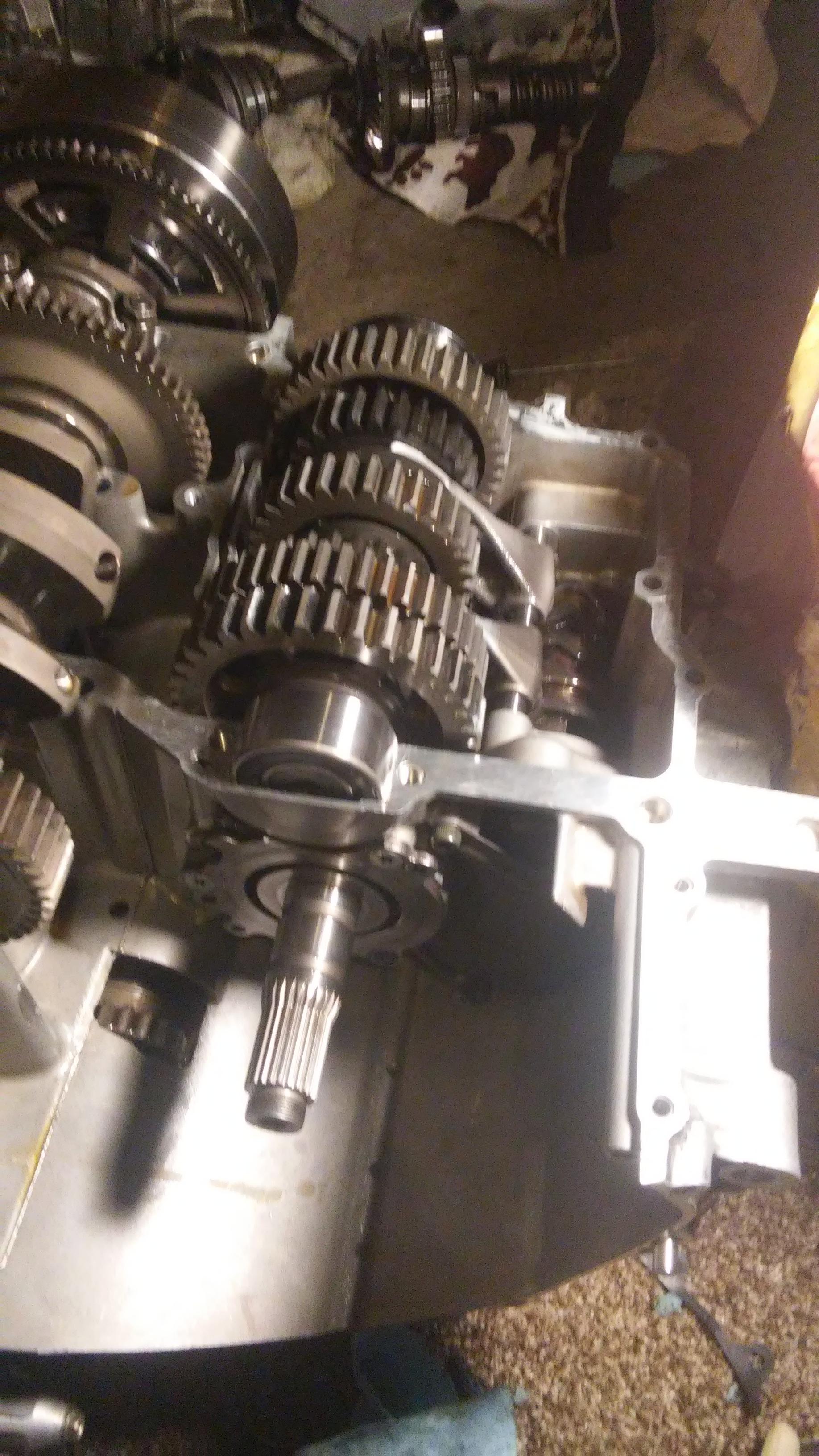

) are the reflection of those parts on the inside wall of the engine case. When I first looked at it before posting, I was thinking, "What the hell is that OTHER gear??!?!!"

) are the reflection of those parts on the inside wall of the engine case. When I first looked at it before posting, I was thinking, "What the hell is that OTHER gear??!?!!"