Here's a data point. I took two

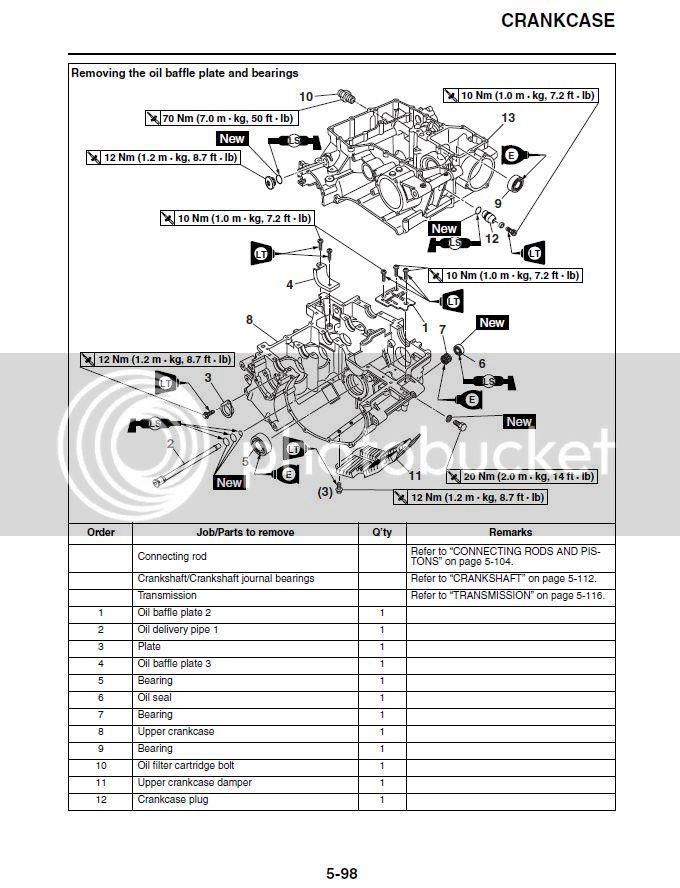

90401-20007-00 unions I had laying around to a local aerospace machine shop in Placentia. I'm having them reduce the width of the 27mm x ~0.200" hex by removing 0.075" off the face of the hex on the short side of the union (oil filter side).

"Turn off 75 thou off of this face right here"

"$40"

"See you tomorrow, thanks"

I did zero shopping around.

I like my cheap Purolators and diesel oil, tyvm.

Thanks to Norm Kern for the how to and measurement posts on the FJR Facebook page awhile back.